WHICH PIPING MATERIALS MAINTAIN WATER PURITY STANDARDS?

When the purity of water and other solutions is critical, each component that comes into contact with the fluid—such as the piping material—must maintain high-purity standards throughout its life. The smallest system impurities can:

- Inhibit the effectiveness of the system

- Reduce the life of expensive systems

- Increase processing downtime

- Cause health issues for the end product

Impurities in a solution are a result of leaching, or the dissolution of metals, solids and chemicals into a fluid.

Consider lead piping, for example. Before the Environmental Protection Agency (EPA) implemented the Lead and Copper Rule (LCR) in 1991, lead piping was used for plumbing. After the lead pipe began to corrode—whether from water temperature, acidity or a lifetime of wear—the lead would leach harmful contaminants into the water supply.

Read on to see why industries should care about leaching and the materials that maintain water purity.

Why Piping Material Specification Matters to Different Processes

Potable Water Processing: As mentioned above, water must be delivered to consumers free of contaminants for obvious safety reasons. While lead may be the most obvious, many other piping materials prone to leaching are still specified and used today.

Power Generation: Deionization and demineralization are important processes that exist to completely remove metal ions from the system. Removing these ions preserves the system equipment—decreasing downtime and increasing the system’s lifecycle. All boiler feed water transported to and from these systems must be completely free of contaminants. If a piping material deposits new ions into the supply, it jeopardizes the purpose of this process.

Food and Beverage, Personal Care, and Biotech: In industries where piping is required to transport the end product consumers will use, contamination causes safety and quality concerns.

Semiconductors: These specialized processing facilities require pristine conditions. Specifically, the chemicals used in lithographic plate etching must be ultrapure. Any metallic ions in the etching solution can threaten the highly detailed production process of expensive chips.

NSF 61: The Water Purity Standard for Piping Materials

NSF 61 is what piping materials are listed to for the safe transport of potable water. It tests for any piping, fixture and joining material or compound that could leach contaminants from the material into the water supply.

NSF 61’s importance is recognized beyond potable water applications, as compliance ensures certain compounds will not leach into the water above a defined threshold.

Comparing Water Purity Performance of Piping Materials

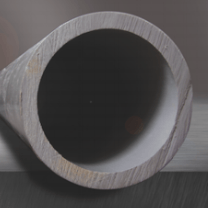

Metallic Piping: Metal piping materials are vulnerable to leaching. Copper, for example, is vulnerable to water below pH 6.5. Corrosion control may be required to limit leaching of copper molecules into the supply. Because of its susceptibility, metal piping materials are not recommended when purity is a priority. See the image of a metal pipe after years of use.

PEX (cross-linked polyethylene): Eight PEX brands do not have NSF 61 ratings in all water conditions and temperatures, including elevated temperatures.

PVDF (polyvinylidene fluoride): Additives ensure non-leaching properties, but PVDF can be costly to maintain.

PVC (polyvinyl chloride): PVC is impervious to corrosion and leaching. However, it does not maintain its physical properties when exposed to elevated fluid or atmospheric temperatures, and users have found it has a lower lifecycle even at low temperatures.

CPVC (chlorinated polyvinyl chloride): CPVC builds on the corrosion resistance and anti-leaching properties of PVC, and delivers superior reliability at increased temperatures and pressures. And, routinely tested to the highest standards of water quality and purity, Corzan CPVC fully complies with NSF 61. See the image of a CPVC pipe after years of use.

Corzan CPVC provides corrosion and leaching resistance that certify its ability to deliver continuous reliability in the long term. If you have questions about the specification of CPVC for your process, our team of product and engineering specialists is available for a free consultation.