CPVC DUCTING

HANGERS & SUPPORTS

TRUSTED PERFORMANCE

FOR LIFE

Partner with BlazeMaster® Fire Protection Systems, the most specified nonmetallic fire sprinkler systems in the world, offering easy installation, inherent corrosion resistance and excellent flame and smoke characteristics.

Corzan® CPVC Ducting requires fewer supports at elevated temperatures than other thermoplastic duct systems thanks to its exceptional heat resistance—a significant cost-savings advantage.

Proper support spacing is dependent on the:

- Duct diameter

- Temperature parameters of the system

- Location of concentrated stress loads

- Possibility of process solids accumulation within the system

As with all piping systems, proper support spacing is critical to ensure that deflection and sagging are kept to a minimum. Doing so prevents unnecessary stress on the system and reduces the possibility of creating fluid condensation/collection areas. Drains must be installed where an accumulation of moisture is expected and at low points in the system; these locations shall be specified on the drawings.

The values in the below table are based on actual testing of

Depending on the type of system service, consideration must be given to the possibility of solids accumulation within the line, particularly where two separate process lines intersect. Solids can be created within a system as the result of a chemical reaction of the fumes being extracted. Stress loads can be generated by the additional weight of accumulated solids, and this fact should be addressed with adequate system support where required.

Proper system inspection, cleaning and maintenance should be enforced to prevent the formation of additional weight loads.

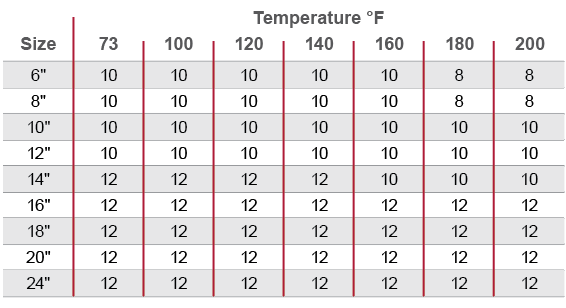

Refer to the following table for maximum support spacing of horizontal air-filled duct at various temperatures.

Maximum Hanger Support Spacing in Feet

As with any system, Corzan CPVC Duct must be independently supported at the following to ensure the highest system integrity:

- Fans

- Flexible connections

- Hoods

- Scrubbers

- Tanks

- Other system components

In the case where flexible connections are installed as expansion joints, a suitable support or hanger shall be provided at each end of the flexible connection. Other heavy system components, such as dampers, filters, etc., must also be independently supported to prevent

Hangers and supports shall be securely fastened to the building structure to avoid

Hangers selected shall have an adequate load-bearing surface free of rough or sharp edges, and shall not cause damage to the duct during use.

The hangers and hanger hardware must also be of a corrosion-resistant material suitable for use in the system environment. Hangers are to be of a type that will not restrict linear movement of the system due to expansion and contraction.

Also, avoid over-tightening to prevent duct deformation and restriction of movement.

Reinforcement

Due to Corzan CPVC Duct’s inherent rigidity and heat resistance, additional system reinforcements or flanges are not required for 6 to 24 in. duct sizes up to 160°F (71.1°C) and 10 in. of negative internal static pressure. This assumes proper support spacing requirements are followed. Additional reinforcements are not required for systems under positive pressure.

Thermal Expansion and Contraction

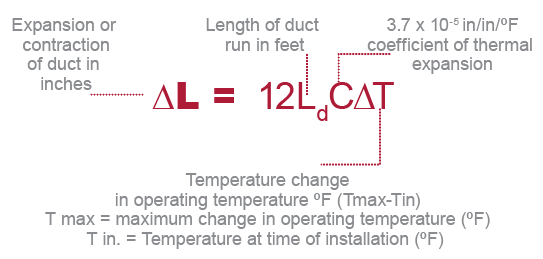

The coefficient of linear expansion (y) for Corzan CPVC Duct is 3.7 x 10-5 in./in./°F, the lowest thermal expansion rate of commonly used thermoplastics.

As with all piping products, thermal expansion and contraction of the system must be considered and properly addressed during the design and installation of the system. The expansion or contraction rate of Corzan CPVC Duct can be calculated as follows:

The most common means to compensate for changes in length is with the installation of in-line expansion joints—either flexible sleeve type or o-ring piston type

The effects of thermal expansion and contraction can also be compensated by using the inherent line flexibility of the system to construct expansion loops and offsets where required. Additional detailed information concerning the effects and control of thermal expansion and contraction, and other information pertaining to the design and installation of CPVC piping