Each year in the United States, an estimated 61 cubic kilometers of wastewater are treated by plants—roughly the volume flowing over Niagara Falls in a year. Nearly 15,000 wastewater treatment plants in the U.S. today treat sewage water, polluted agricultural water and industrial plant wastewater.

Through a series of processes that vary by plant, contaminated water is transformed to clean water for release into the environment or use by other industrial processes.

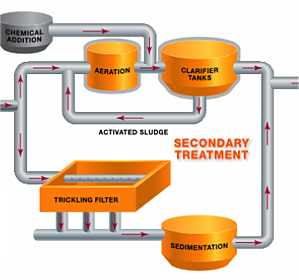

The process starts with primary treatment, where large objects and solids are filtered out from the influent. The resulting effluent is then treated chemically or microbiologically during secondary treatment, which continues to advanced treatment if any harmful chemicals are still present in the water.

During the process, large vessels and piping systems must convey and handle very polluted water, highly corrosive and caustic chemicals, and other demanding environmental and system conditions. To keep plants efficient and cost-effective, appropriate material selection is critical.

Material Options

The corrosive environments of wastewater treatment plants typically pass on metals in preference of plastic piping. Plastic piping is inherently resistant to many of the contaminants in wastewater and the treatment process, such as salts and minerals, and the chemicals used to treat the water, including strong acids and bases.

For some facilities, polyvinyl chloride (PVC) is used as a cost-effective option that provides serviceable performance.

However, due to the full pH range subjected to the lines, consistent quality concerns and the potential high heat created by exothermic reactions in the process, PVC is not always the best option for maximizing full lifetime value. Other plastics considered for most lines include chlorinated polyvinyl chloride (CPVC), polypropylene (PP) and polyvinylidene fluoride (PVDF).

A Reliable Choice

An advanced thermoplastic, which builds upon the advantages of PVC, is chlorinated polyvinyl chloride (CPVC). Commercialized by Lubrizol nearly 60 years ago, CPVC is a specially engineered thermoplastic with excellent corrosion resistance, impact strength and temperature resistance. The need for a consistent quality thermoplastic was a leading factor in Lubrizol creating the Corzan CPVC technology. Today, it is one of the most specified industrial CPVC materials in the world. Engineers have confidence in Corzan CPVC, regardless of the manufacturer, and specify around the technology.

CPVC, an effective wastewater treatment plant material for decades, continues to assert more prominence in the industry through a reputation of long-lasting, reliable and efficient systems.

Why CPVC for Wastewater Treatment?

CPVC is a high-performance industrial piping material specially engineered to meet the demands of wastewater treatment plants, creating greater reliability and better performance for an extended service life.

Specific advantages of CPVC:

- Significantly lowers life-cycle costs over metallic systems and requires significantly less maintenance than less expensive plastics

- Eliminates internal and external corrosion caused by many corrosive chemicals

- Blocks the degrading effects of chemicals, microorganisms and UV light

- Ensures optimal flow rates with excellent hydraulic capabilities and pressure ratings up to 200°F (93.3°C)—nearly 80°F (45°C) higher than PVC

- Achieves long-term performance with superior mechanical strength, and Corzan® CPVC has the highest impact resistance (24448 cell class up to 8-in. diameter, as defined by ASTM-D1784) of any CPVC pipe compound

- Comes in diameters up to 24-in (check with each manufacturer)

- Reduces installation time with a lightweight design (1/8 the weight of steel) and joining systems that eliminate the need for torches or complicated heat-fusion techniques

- Decreases total installation costs attributed to lower material costs and installation time, as compared to metallic alternatives

- Meets and exceeds regulatory requirements, including smoke and flame resistance and NSF International standards for potable water safety

CPVC Stands Up to the Most Aggressive Chemicals

Corzan CPVC provides superior lifetime resistance to corrosive chemicals and water of all purity levels—even at high temperatures. In fact, CPVC pipes and fittings effectively stand up to most acids, bases and salts.

Most of the aggressive chemicals involved and used during the wastewater treatment process are compatible with CPVC, including:

Chemical Compatibility of CPVC

|

Type |

Chemical |

Maximum Temperature |

|

Coagulants, Flocculants and Precipitants |

Aluminum Sulfate (Alum) |

200°F (93°C) |

|

Aluminum Chloride |

200°F (93°C) |

|

|

Calcium Hydroxide (Lime) |

200°F (93°C) |

|

|

Ferric Chloride |

200°F (93°C) |

|

|

Ferric Sulfate |

200°F (93°C) |

|

|

Ferrous Chloride |

200°F (93°C) |

|

|

Ferrous Sulfate |

200°F (93°C) |

|

|

Sodium Aluminate |

200°F (93°C) |

|

|

pH Control |

Calcium Carbonate |

200°F (93°C) |

|

Calcium Oxide |

200°F (93°C) |

|

|

Carbon Dioxide |

200°F (93°C) |

|

|

Carbonic Acid |

200°F (93°C) |

|

|

Hydrochloric Acid |

180°F (82°C) |

|

|

Magnesium Hydroxide |

200°F (93°C) |

|

|

Magnesium Oxide |

200°F (93°C) |

|

|

Sodium Bicarbonate |

200°F (93°C) |

|

|

Sodium Carbonate (Soda Ash) |

200°F (93°C) |

|

|

Sodium Hydroxide (Caustic Soda) |

Contact Lubrizol |

|

|

Sulfuric Acid |

Depends on Concentration (Contact Lubrizol) |

|

|

Disinfectants, Odor Control and Color Removal |

Ammonia in Solution |

Usually 200°F (93°C) |

|

Calcium Hypochlorite |

200°F (93°C) |

|

|

Chlorine Dioxide |

200°F (93°C) |

|

|

Fluosilicic Acid, 30% |

180°F (82°C) |

|

|

Hydrofluosilicic Acid, 30% |

180°F (82°C) |

|

|

Hydrogen Peroxide, 10% |

180°F (82°C) |

|

|

Hydrogen Peroxide, 50% |

120°F (50°C) |

|

|

Ozone (Aqueous) |

200°F (93°C) |

|

|

Peracetic Acid |

Depends on Concentration |

|

|

Potassium Permanganate |

180°F (82°C) |

|

|

Sodium Hypochlorite |

200°F (93°C) |

|

|

Sodium Sulfite |

200°F (93°C) |

|

|

Sodium Bisulfite |

200°F (93°C) |

|

|

Sulfur Dioxide |

200°F (93°C) |

Information is based on Corzan Industrial Systems’ Chemical Resistance Data. View the Corzan CPVC Chemical Resistance Table of more than 400 chemicals and compounds. Check with your manufacturer to confirm compatibility.

System Installation Time and Reliability

Installation cost and time can sometimes account for more than half of the total cost of a system.

Compared to metals, CPVC cuts installation costs and time significantly due to the following advantages:

- No need for a designated welding area

- No costly hot work permits

- Does not require an experienced, certified welder

- No need for heavy and expensive equipment

- Lighter and easier to move and secure

CPVC is typically installed through a simple step-by-step solvent cement joining process. With solvent cement, the pipe and fitting fuse together at the molecular level, forming a uniform piece of material. Where other materials are often vulnerable, CPVC solvent cemented joints are often the stronger part of a system, translating to greater reliability, fewer repairs and a longer service life. In addition, ASME B31.3 bonder training is available and recommended for all installers.

Where Can CPVC Be Used in Wastewater Treatment Plants?

CPVC piping is depended on by all types of wastewater treatment plants around the globe. Take for example, sewage plants, industrial wastewater treatment plants and agricultural treatment plants. Each has unique system characteristics that call upon the strengths and unique capabilities of CPVC.

System Specific Applications

Throughout a wastewater treatment plant, like the general one shown in the diagram above, CPVC has many potential uses—illustrated in gray. Essentially, anywhere piping is used to convey a fluid or other medium, CPVC is an option.

Not shown in the diagram are all of the various lines and storage tanks used for chemicals injection throughout the system. CPVC performs especially well against these substances.

Primary Treatment

The purpose of primary treatment is to take wastewater from drains and sewers, and remove any solid particles that cannot be removed by chemicals.

CPVC can be used in primary wastewater treatment for:

- Bar screens

- Scum and grit removal

- Filtering equipment

- Chemical addition tanks

- Sludge removal, including anaerobic digestion and dewatering

Why CPVC for Primary Treatment and Sludge Removal

The most common and cost-effective use of CPVC during primary treatment and sludge removal is for conveying injection chemicals into the process.

Highly acidic chemicals are used to remove unwanted contaminants from the water. Ferric chloride, for example, precipitates phosphorous to allow it to settle in the sedimentation tank. Phosphorous is a leading factor in eutrophication, which devastates water with excessive plant and algae growth. With ferric chloride and ferrous chloride, CPVC is recommended up to 200°F (93.3°C).

CPVC stands up to many other chemicals and potential contaminants involved in primary wastewater treatment, including:

- Microbial growth

- Abrasives

- Ferrous chloride

- Ferric chloride

- Alum

- Alkaline lime slurry systems that neutralize the acid generated during the nitrification of ammonia

An important characteristic of primary treatment influent piping is the material’s resistance to scaling and fouling. Due to the characteristics of the untreated raw influent, minerals like calcium and magnesium can deposit on piping materials—most notably metals.

CPVC is resistant to this occurrence.

Pictured are two pipes after years in use. The metal pipe is affected by corrosion, while the CPVC maintained its surface smoothness and inside diameter.

Secondary Treatment

The effluent from primary treatment should be free of suspended solids and anything that cannot be removed through chemical processes. During secondary treatment, 85% of organic matter should be removed.

This is accomplished through:

- Trickling filter or biofilter

- Aeration (an activated sludge process)

- Clarifier tanks

Why CPVC for Secondary Treatment

As with primary treatment, CPVC continues to be a preferred conveyer of injection chemicals during secondary treatment.

CPVC stands up to many of the chemicals and other contaminants involved in secondary wastewater treatment, including:

- Oxygen, used for aeration

- Microbes, such as acids or hydrogen sulfide

- Highly concentrated acids and caustic solutions used for pH control, for example magnesium hydroxide and hydrochloric acid.

- Disinfectants, including calcium hypochlorite and sodium sulfite

- Dechlorination chemicals, such as hydrogen peroxide and sodium bisulfite

During aeration, when oxygen is pumped into the wastewater, high concentrations of microorganisms can occur. This excessive biological growth washes out and collects in the clarifier tanks. CPVC resists biofilm formation, which pollutes the water and can also buildup and hinder efficiency.

The Hazen Williams C Factor is an important figure for flow dynamics. It compares the smoothness of different materials, where the higher the C Factor, the smoother, more consistent the material surface is. At installation, CPVC has a C Factor of 150, which is mostly maintained throughout its life. Alternatively, new stainless steel has a C Factor around 130, but can end up well below 100 after years of use.

The result: greater lifetime efficiency for CPVC, allowing for smaller, less expensive pumps and lower consumption costs.

Also, secondary treatment piping and tanks are often installed outdoors. Corzan CPVC is specially engineered with additives to lessen the impact of UV weatherability if the owner chooses not to paint or cover the material.

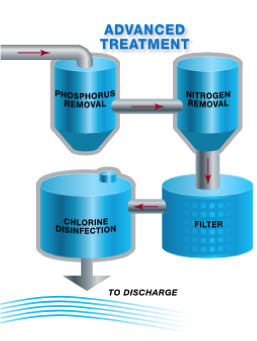

Advanced Treatment

The most common purpose of advanced or tertiary treatment is to

disinfect the water of pathogenic microorganisms an

Chlorine disinfectiond viruses. Various processes may be involved, depending on regulatory standards and the region’s water quality.

- Ozone disinfection

- UV light

- Phosphorous and nitrogen removal

- Cooling water systems

Why CPVC for Advanced Treatment

Advanced treatment is the most common use for CPVC in wastewater treatment plants. Due to the high number of corrosive and caustic chemicals added to the system at this point, piping must stand up to corrosion, temperatures and pressures.

Where can CPVC be an ideal fit for advanced wastewater treatment?

Cooling water systems: To meet regulatory standards upon discharge, water may need to be cooled before release into the environment. Cooling pipes may be installed underground or outside, and CPVC’s ability to resist external corrosion, prevent biofilm formation and avoid UV weatherability makes it an ideal fit. It is very common to utilize Corzan CPVC in double containment systems when necessary to meet regulatory requirements.

Phosphorous and nitrogen removal: CPVC effectively stands up to dilute methanol and nitrates, two chemicals frequently used for phosphorous and nitrogen removal during advanced treatment.

Underground treatment chemical conveyance: Environmental regulations often require double containment systems be used for underground chemical piping. Corzan CPVC systems can deliver in this situation, as it is pressure rated up to 200°F (93.3°C), even when conveying many corrosive or caustic chemicals.

Is CPVC Right for Your Wastewater Treatment Plant?

CPVC offers advantages that can be recognized across the plant. For dealing with the potentially corrosive and high temperature environment of a wastewater treatment facility, know that not all CPVC is created equal.

As with all materials, quality matters.

When compared to other CPVC brands, Corzan CPVC testing confirms better consistency and performance in terms of:

- Minimum burst pressure requirements

- Dimensional tolerances

- Residual stress requirements

- Drop impact requirements

- Fusion property testing

Due to our intense quality controls and superior compound, the high performance characteristics of Corzan CPVC is consistent regardless of which partner manufacturer creates it, when it is manufactured or which region of the world it comes from.

Corzan Industrial Systems has a proven track record of dependable service in wastewater treatment plants. Our specifically engineered material provides an excellent balance of properties to improve reliability and user confidence. It reduces capital and life-cycle costs, and, most importantly, allows wastewater treatment plants to avoid unnecessary shutdowns and stay more productive.

To determine if Corzan CPVC is right for your plant or any specific plant system, please schedule a free consultation with our technical support team. They can provide a free process suitability review and offer an honest assessment of whether our material can satisfy your plant’s needs.

Download as a PDF

To view this page as a printable PDF, fill out this form.