SHEET & LINING

HIGH SPEED HOT AIR WELDING

SHEET & LINING

HIGH SPEED HOT AIR WELDING

The Principle of Thermoplastic Welding

In order to weld thermoplastics, the material must be heated to reach its melt state. The pieces to be welded must then be pressed together with a certain amount of pressure over a given amount of time. The heat and pressure will allow the surface molecules of the parts to interlock, fusing the parts together.

High Speed Hot Air Welding

Corzan® system components can be hot air welded to give approximately 80% of the tensile strength of solid sheet. Actual performance will depend upon the equipment used, the welding conditions employed, and the individual technique of the person doing the welding. As a result, the recommendations given on this page are intended to be general guidelines and do not guarantee actual performance.

The Essentials of Hot Air Welding Corzan CPVC

- Clean, dry air

- Accurate temperature control

- Beveled edges on base material

- Buff or scrape welding surface and rod

- Base material and rod both Corzan CPVC

- Ideal rod diameter 1/8 - 5/32-in.

- Optimum temperature range:

-

710-800°F (375-425°C) - Dial Selected

- 680-770°F (360-410°C) - Measured and adjusted - 3/16-in. (5mm) inside main opening of welding tip.

-

- Optimum air flow: 40-60 lpm

Equipment

When thermoplastics are being welded, the quality of the air used as the heat transfer medium is a critical factor in the quality of the weld.

High-speed hot air welding requires the use of air that is supplied at low pressure and high volume and is free of oil and moisture. Common shop compressors generally do not supply air of adequate quality for use in high-speed hot air welding. Many manufacturers of hot air welding equipment also have blowers available that are specifically suited for this purpose.

When Corzan system components are being welded, the accuracy of the temperature controlling equipment is equally as important as the quality of the air. The optimum temperature range for welding Corzan system components is typically slightly narrower than for other thermoplastics, such as polyolefins. The quality of the weld produced is therefore dependent on having a constant temperature at the welding tip.

Welding equipment for use with Corzan system components preferably should control the temperature by regulating power to the heating element, not by varying the air flow. The ideal temperature control arrangement for welding Corzan system components should incorporate closed loop controls, which hold the temperature constant even while air flow or supply voltages fluctuate.

A high speed welding tip is designed to perform three functions:

- Preheating the base material

- Guiding and preheating the welding rod

- Applying pressure to the weld area

Material Preparation

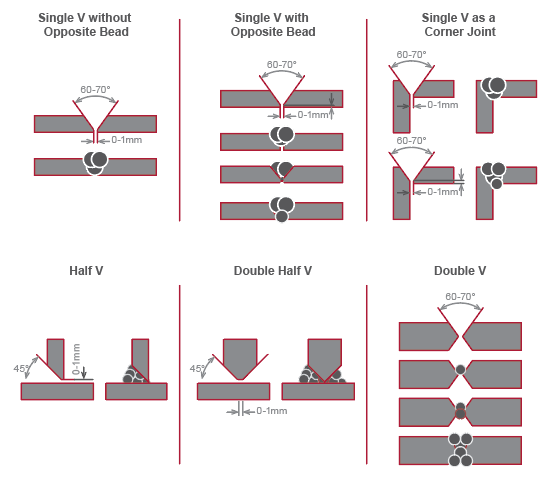

The ends of the pieces of material to be joined must be beveled in order to produce the best weld. The bevel may be produced with an adjustable saw, a router or other suitable tool. The angle between the bevels of the two pieces to be joined should be between 60 and 70°, except when one piece is joined perpendicularly to another, in which case, the angle is reduced to 45°.

The parts to be assembled must be very clean. To remove surface residue, slight grinding or scraping with a sharp blade at the area to be welded and the weld rod is strongly recommended. Acetone is the only solvent that is suitable for use to clean the area to be welded. Other solvents may have potentially negative effects on Corzan CPVC.

If the joint will not be tacked prior to welding, it is recommended to leave a gap of 0.5 to 1 mm wide between the two pieces to be joined so that the welding material may penetrate to the root of the bevel and overflow slightly on the other side. If the parts will first be tacked, they should be butted together with no gap. The parts to be joined should be mounted firmly in place with appropriate clamps as necessary.

Welding Rod Selection

When Corzan CPVC parts are being joined, the welding rod selected should also be produced from Corzan CPVC. Triangular rod may be used where the appearance of the joint is the most important factor, but round welding rod should be used when structural integrity is desired.

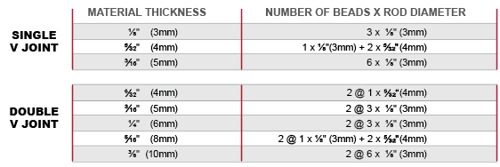

While welding rod is commonly available in sizes up to 1/4 in. (6 mm) in diameter, the strongest joints are obtained by using rod in smaller diameters with multiple beads as necessary. In order to obtain the strongest weld with Corzan welding rod, it is recommended to use rod no larger than 5/32 in. (4 mm) in diameter.

It is important to match the diameter of the welding tip with the diameter of the rod selected. An oversized tip will negatively affect guidance and pressure applied to the rod and may also cut into the parts being welded.

Tack Welding

The first step in the process is tack welding. The objective is to put the parts in place, align them, and prevent any slippage of the material during the structural welding process.

Tacking is done with a pointed shoe tip. The operator places the tacking tip directly on the material to be welded and draws it along the joint. Hot air from the welder softens the material, and pressure applied by the operator to the tip fuses the material together. Continuous or spot tack welding may be used as necessary. Larger structures or thick gauge materials may require additional clamping.

Any tank should be tack welded continuously to achieve a leak free connection. This prevents solutions from penetrating between the tank wall and the bottom in case of a problem with the filler weld.

The Welding Process

The optimum temperature range for hot air welding of Corzan system components is dependent on the type of welding equipment being used and the way in which the temperature is measured.

If the welding torch incorporates closed-loop controls, which maintain the temperature selected on a dial setting, the optimum range is typically 710 to 800°F (375 to 425°C). If the temperature cannot be directly selected on a dial setting, it must be measured by the operator and then adjusted by varying power to the heating element or regulating the air flow. The temperature should be measured with a pyrometer approximately 3/16 in. (5 mm) inside the main opening of the high speed welding tip. When the temperature is controlled in this manner, the optimum temperature for welding Corzan system components is typically 680 to 770°F (360 to 410°C).

The actual temperature within the range that will produce the best weld will depend on a number of factors and must be adjusted accordingly. The list of variables includes, but is not limited to:

- Diameter of rod

- Brand of rod

- Speed of welding

- Ambient temperature

To make it easier to initiate welding, a sharp angle may be cut on the lead end of the welding rod. The welding rod should not be inserted into the high speed-welding tip until immediately before the operator is ready to begin welding. Otherwise, the rod may burn.

To begin welding, the operator should grasp the welding torch like a dagger, with the airline trailing away from his body or over the shoulder so that he will be able to operate quickly and smoothly once he has begun.

Holding the welding tip approximately 8 cm above the area to be welded to prevent scorching the material before work begins, insert the welding rod into the preheating tube and then place the pointed tip of the shoe on the material at the starting point of the weld. Holding the welder at roughly a 45° angle, push the rod through the tip until it contacts the base material.

Continue to feed the rod with the other hand, using slight pressure. If the rod is not guided, the welding rod will stretch fully apart. The weight of the welder is the only pressure needed as the weld is pulled along the joint.

As welding progresses, visual inspection of the weld may indicate its quality. Browned or charred edges occur when the welder is moving too slowly and/or overheating. If the rod has been softened too much by overheating, it will stretch and break or flatten out. Once welding begins, it must be continued at a fairly constant rate of speed. The welding torch must not be held still, or burning will result.

To stop welding before the rod is used up, the operator should tilt the welder backward, cut the rod off with the tip of the shoe and immediately remove the remaining rod from the welding tip. Welding may also be terminated by pulling the welder tip up over the remaining rod and cutting the rod. For best results, the welding tip should be cleaned occasionally with a wire brush. Multiple beads should be applied as necessary until the joint is completely filled, as shown in Figure 2.

If the joint to be welded is a double V or a double half V joint, the best results are obtained if layers of beads are put down alternately on opposite sides of the joint. The table below presents recommendations for bead lay-up for different material thicknesses and joint configurations.

Recommendations for Bead Lay Up

Heat Stress Problems

During hot air welding, the material will expand as it is forced into position. When cooling, it will shrink back to its original volume. A welded sheet that is straight while still hot may become bent after cooling. Using a double V joint is one way to avoid this problem.

Weld Factor

When properly hot air welded, Corzan CPVC sheet can be expected to perform to approximately 80% of its nominal tensile strength.