Specification

THERMAL EXPANSION & STRESS

Specification

THERMAL EXPANSION & STRESS

It is important to consider thermal expansion when designing any piping system, including one made of Corzan® CPVC material.

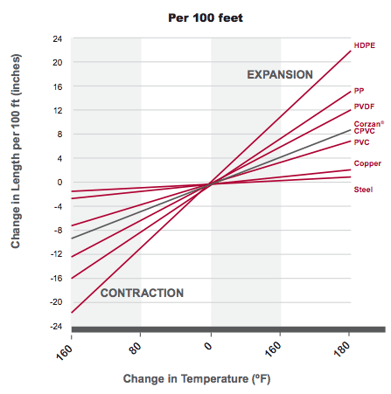

Most thermoplastics have a coefficient of thermal expansion that is significantly higher than those of metals. The linear thermal expansion of a piping system subject to a temperature change can therefore be significant, and may need compensation in the system design.

Linear Thermal Expansion of Piping Material

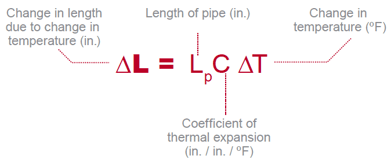

The expansion or contraction of thermoplastic pipe may be calculated from the following formula, or by using Corzan Industrial System’s Thermal Expansion Calculator.

Thermal Expansion Formula

How to Account for Expansion and Contraction

As a rule of thumb, if the total temperature change is greater than 30°F, compensation for thermal expansion should be included in the system design.

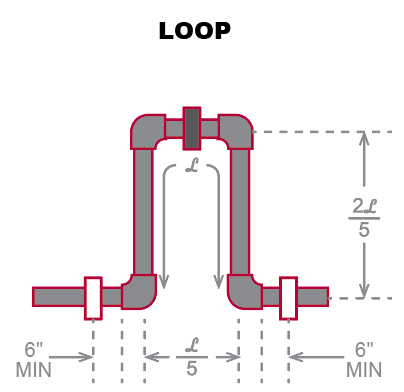

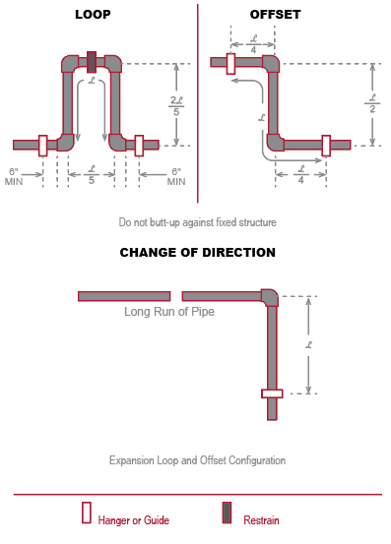

The recommended method for accommodating thermal expansion is to include expansion loops, offsets, or changes in direction where necessary in the system design.

Expansion Diagrams

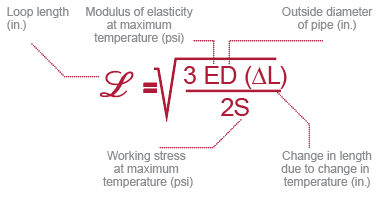

Expansion Loop Formula

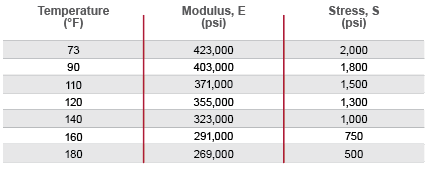

Working Stress and Modulus of Elasticity of Corzan® CPVC

Expansion loops and offsets should be constructed with straight pipe and 90° elbows, which are solvent cemented together. If threaded pipe is used in the rest of the system, it is still recommended that expansion loops and offsets be constructed with solvent cement to allow the mechanisms to better handle the bending stresses incurred during expansion and contraction.

The expansion loops and offsets should be located approximately at the midpoint of the pipe run. Valves or strainers should not be installed within an expansion loop or offset.

Thermal Stresses

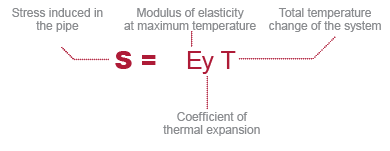

If thermal expansion is not accommodated, it is absorbed in the pipe as an internal compression. This creates a compressive stress in the pipe. The stress induced in a pipe, which is restrained from expanding is calculated with the following formula:

Impact of Thermal Stress on CPVC vs. Steel

Because the coefficient of thermal expansion of steel is five times lower than that of CPVC, dimensional change due to thermal expansion will be five times less.

However, as can be seen by the equation above, the stresses induced in the piping system due to restrained thermal expansion are dependent on the material’s modulus as well as its coefficient of thermal expansion.

Because the modulus of steel is approximately 80 times higher than that of CPVC, the stresses resulting from restrained expansion over a given temperature change will be approximately 16 times higher for steel than for CPVC.

For instance, restrained expansion over a 50°F temperature change will produce approximately 600 psi of stress in a CPVC system, but 9800 psi of stress in a steel system. CPVC’s relatively more flexible nature will usually allow it to absorb its lower stresses in a buckling or snaking of the line if necessary. Because steel piping is too rigid to buckle, its higher stresses are often transferred to surrounding structures, resulting in damaged supports, anchors or even abutting walls.