CPVC vs Steel Piping Systems

Which Piping Material Performs Better In Industrial Applications?

WHAT IS CPVC?

The qualities and attributes that define Corzan® CPVC and why it is the material of choice for industrial systems around the world

Is Plastic Better than Steel?

For decades, metal piping systems have been the status quo for many industrial applications. Galvanized steel, stainless steel and other alloys are strong, durable and capable of standing up to the high heat and elevated pressure demands of these environments.

The other, underlying reason metal systems are commonly specified is they’re the familiar choice. Engineers have acquired a thorough understanding of the material’s capabilities, including when issues will arise and the extent of those issues.

When talking about industrial piping systems, any decision to transition away from the known to the unknown is done with no small degree of hesitation, and with good reason. Any misstep could cost a company millions, and the engineer his or her reputation.

What is Chlorinated Polyvinyl Chloride?

Chlorinated polyvinyl chloride (CPVC) is an important engineering thermoplastic due to its relatively low cost, high glass transition temperature, high heat distortion temperature, chemical inertness, and outstanding mechanical, dielectric, and flame and smoke properties.

Conceptually, CPVC is a PVC homopolymer that has been subjected to a chlorination reaction. Typically, chlorine and PVC react according to a basic free radical mechanism, which can be brought about by various approaches using thermal and/or UV energy.

Creating Heat Resistance to Rival Steel

The chlorine content of base PVC can be increased from 56.7 percent to as high as 74 percent, though typically most commercial CPVC resins contain 63 to 69 percent chlorine. As the chlorine content in CPVC is increased, the glass transition temperature (Tg)—temperature region where the polymer transitions from hard, glassy material to a soft, rubbery material—increases significantly.

The additional chlorine atoms protect the polymer’s carbon backbone against chemical attack, and give it greater heat resistance. The increased heat resistance allows CPVC to be pressure-rated at higher temperatures. The compound is also inherently inert to acids, bases, salts, and aliphatic hydrocarbons, all of which tend to corrode metals.

Why Corzan CPVC?

CPVC technology was specifically engineered to satisfy the demands of harsh industrial process environments. In 1958, Lubrizol was the first to formulate CPVC into a useful material for pipes and fittings. Corzan® CPVC is a thermoplastic capable of withstanding prolonged exposure to high heat and elevated pressure while offering superior corrosion resistance.

CPVC vs Steel: Putting on the Pressure

A material’s ability to withstand high heat and pressure for prolonged periods of time is essential to the performance of an industrial system. Any weakness here and plant operation managers will be regularly performing repairs, shutting down the system for unscheduled maintenance, and potentially replacing the piping system prematurely.

Metal has proven itself capable of satisfying heat and pressure requirements, but what about CPVC?

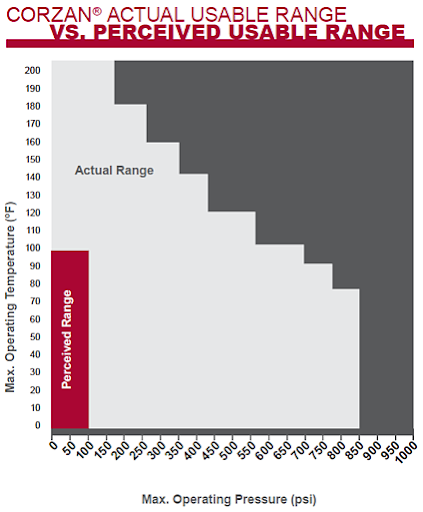

The following is Corzan CPVC’s maximum operating temperature and pressure range as determined by ASTM D2837F441. The red area is what most engineers perceive CPVC’s capabilities to be. The light gray is Corzan CPVC’s actual full operating range.

How Long Do Steel Pipes Last?

The most significant advantage a CPVC piping system has over galvanised steel is its corrosion resistance.

Metals may corrode by pitting corrosion wherein tiny pits form along the length of the pipe diminishing the pipe’s wall thickness and reducing its pressure bearing capability.

Another cause for concern is crevice corrosion. This is where ions in the fluid concentrate in crevices around welds, flanges and other types of pipe connections. This ion buildup can degrade material quickly causing leaks at welds and joints.

Conversely, pipes and fitting made with CPVC material are inherently inert to most acids, bases, and salts, meaning the aggressive ions that attack metals flow right past CPVC, leaving the piping unscathed.

Which Pipe Is Best For Water Supply?

One of the biggest threats to industrial piping in water distribution is scaling, as it can significantly jeopardize flow rates.

At different pH levels and temperature ranges, certain metal ions are water soluble, which allows them to flow through a metal piping system with little to no problem.

However, if the fluid a metal is dissolved it falls outside of its solubility range, ions can drop out of the solution and attach to the walls of a metal pipe. These ions build up over time to create what look like scales around the inside of the pipe.

Galvanized steel pipes are known for scale buildup over time. With CPVC, there is little concern of scaling. The material has a significantly lower affinity to scaling than metals. Corzan piping's Hazen Williams C-factor rating of flow friction is 150, and it can maintain this rating throughout its life.

Which Pipe is more expensive – Steel or Plastic?

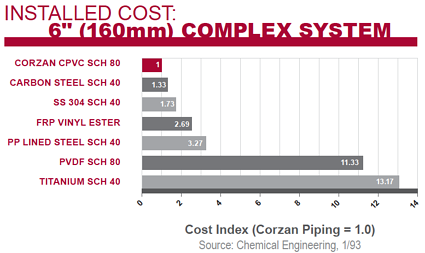

Labor, fabrication and other installation expenses can combine to account for more than half of a piping system’s total installed cost. The following graph with data produced by Chemical Engineering Magazine shows the cost index of installing Corzan 6-in. CPVC piping systems compared to metal and thermoplastic alternatives.

When it comes to installation, CPVC holds a number of advantages over metal alternatives. Here is why a Corzan system offers one of the lowest installed costs of any piping material:

Joint Welding - Metal piping seams are welded together using intense heat and often a metal filler. CPVC systems are fused together using a straightforward, two-step solvent cement process.

Weight - CPVC weighs 1/6th that of comparably sized steel. A 6-in., schedule 80 Corzan pipe weighs about 6 lbs./ft., whereas the equivalent steel pipe can weigh between 25 and 29 lbs./ft. (based on a sampling of steel piping manufacturers.)

Labor and Equipment - The weight of a metal piping system requires that more laborers be involved to handle, install and secure the piping. In addition, heavy machinery will need to be available to transport and hoist the piping into place. In addition, labor costs escalate as laborer skill-level demands increase. This is especially relevant for seam welds.

Fabrication - Due to its weight, need for specialized welding techniques, and electricity / flame requirements, much of a metal piping system is prefabricated offsite and trucked to the facility.

This process can prove expensive as special accommodations are made to ship the piping. In addition, there is limited room for error. CPVC can be prefabricated, but thanks to its two-step solvent cement welding process

Maintenance - With minor training for solvent welding of CPVC pipes and fittings, any mechanical contractor or plant maintenance engineer can change, repair and modify the system. The piping itself is also flexible to a point, so one or two men without specialized equipment can easily make alignment adjustments.

Which Pipe is Safer, Plastic or Steel?

CPVC also offers a number of safety advantages over metal alternatives.

Thermal Conductivity

CPVC has a very low thermal conductivity value. The heat transfer coefficient of Corzan CPVC is approximately 1/300th that of steel, saving energy costs and offering a much cooler surface temperature. Not only does this also reduce the need for costly insulation, it limits worker exposure to burn hazards.

Fire Safety

CPVC will not sustain burning. This is thanks to its Limiting Oxygen Index (LOI) of 60. LOI is the percentage of oxygen needed in an atmosphere to support combustion.

Since Earth’s atmosphere is only 21 percent oxygen, Corzan pipe or fitting will not burn unless a flame is constantly applied to it, and it will stop burning as soon as the ignition source is removed.

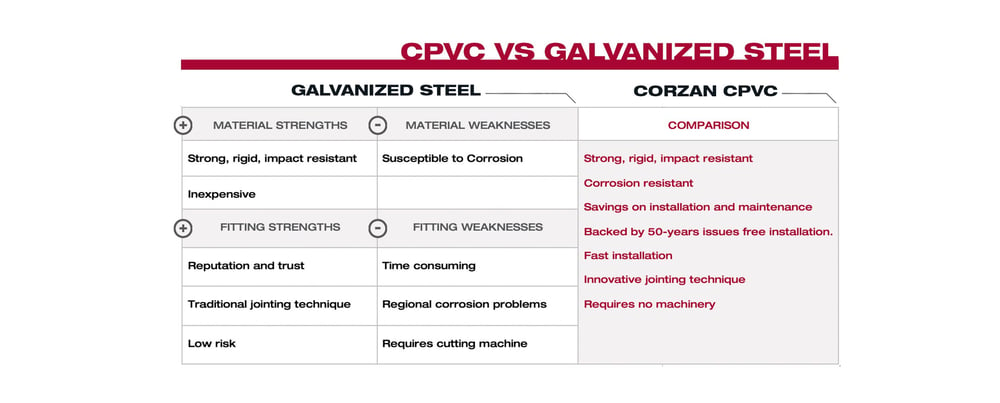

CPVC vs Galvanized Steel

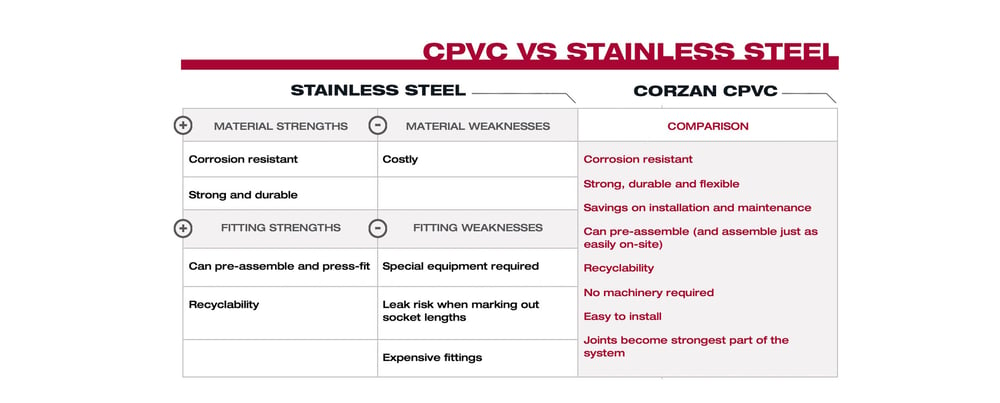

CPVC vs Stainless Steel

If you’re interested in learning more about Corzan CPVC, or simply have questions about the process of transitioning away from a metal piping system, contact us.