WHAT IS CPVC?

The qualities and attributes that define Corzan® CPVC and why it is the material of choice for industrial systems around the world

WHAT IS CPVC?

The qualities and attributes that define Corzan® CPVC and why it is the material of choice for industrial systems around the world

First commercialized by Lubrizol in the early 1960s, Chlorinated Polyvinyl Chloride (CPVC) has proven its value across a variety of industrial applications where high use temperature, high pressure and resistance to corrosion and microbials, are required.

CPVC is recognised as an important engineering thermoplastic due to qualities such as:

- High glass transition temperature

- High heat distortion temperature

- Chemical inertness

- Outstanding mechanical, dielectric, and flame and smoke properties

- Relative low cost to manufacture and install

Today, Lubrizol's CPVC compound is blended and sold under three brand names:

- Corzan® Industrial Systems for industrial applications

- BlazeMaster® for fire sprinkler systems

- FlowGuard® for residential and commercial plumbing

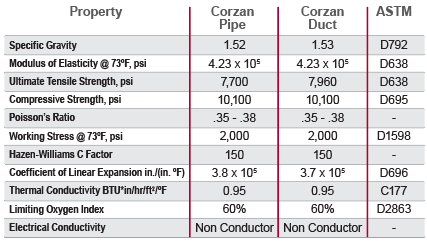

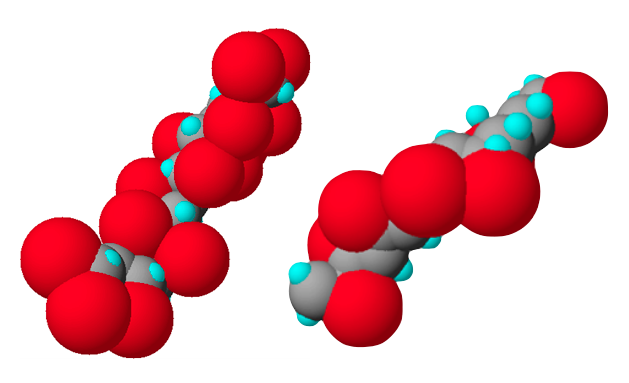

Corzan® CPVC: Basic Physical Properties

CPVC is a PVC homopolymer that has been subjected to a chlorination reaction. Typically, chlorine and PVC react according to a basic free radical mechanism, brought about by various approaches using thermal and/or UV energy.

CPVC is inherently inert to acids, bases, salts and aliphatic hydrocarbons, all of which commonly eat away at metals. It's this inherent chemical resistance, combined with its temperature and pressure resistance, that enables CPVC to meet a variety of industrial and commercial applications.

Find out more about Corzan® CPVC Technical Aspects

What is the difference between CPVC and PVC?

In PVC, a chlorine atom occupies 25% of the bonding sites on the carbon backbone - the remaining sites are filled by hydrogen. CPVC differs from PVC in that approximately 40% of the bonding sites on the backbone are occupied with chlorine atoms. The chlorine atoms surrounding the carbon backbone of CPVC are large atoms that protect the chain from degradation.

The chlorine content of base PVC can be increased from 56.7% to as high as 74%; typically, most commercial CPVC resins are measured to contain 63% to 69% chlorine.

CPVC surpasses PVC for industrial applications thanks to its increased resistance to chemicals and temperatures, combined with the manufacturing processes instilled to increase strength and durability.

Increased Temperature Resistance

As the chlorine content in CPVC is increased, the glass transition temperature (Tg)—temperature region where the polymer transitions from hard, glassy material to a soft, rubbery material—increases significantly. It’s the additional chlorine molecules that protect the polymer’s carbon backbone, which in turn protects its structural integrity against heat.

The increased heat resistance allows CPVC to perform at higher operating pressures than PVC.

CPVC Additives

CPVC resin is infused with additives to enhance many of the CPVC resin’s inherent properties, while easing its processability. This process sets CPVC apart from other thermoplastic and metal piping systems, fortifying it against the demanding environments of industrial processing plants.

Not All CPVC Is The Same

Although CPVC as an industrial piping material has a long, proven history, not all CPVC systems are equal in performance or fit for long-lasting use in application environments.

While some bottom-line benefits of CPVC are common regardless of manufacturer, CPVC compounds are often differentiated by the level of performance they provide. Just as two different metallic piping systems will likely perform differently, it’s logical to understand different types of CPVC industrial pipe, produced from different compounds, will yield contrasting results.

Corzan® Industrial Systems, and our partner manufacturers have undergone rigorous and varying types of tests regarding:

- Minimum burst pressure requirements

- Dimensional tolerances

- Residual stress requirements

- Drop impact requirements

- Fusion property testing

We recommend gaining clarification on the testing of any material you are considering for your industrial system.

Why Corzan® CPVC Is The Dependable Choice For Industrial Applications

Discover why Corzan® Industrial Systems is the preferred brand of choice in delivering system components and complete systems, to meet a range of industrial applications and the demands each present.

- Corzan® CPVC and Superior Specification Capabilities

- Corzan® CPVC and Quick, Simple And Efficient Installation

- Corzan® CPVC: Proven Reliability Across A Variety Of Industrial Applications

- Corzan® CPVC: A Complete Industrial System

Where To Purchase Corzan® CPVC

Corzan® Industrial Systems only partners with manufacturers that have a proven track record of quality and reliability. We carefully select manufacturers based on their ability to consistently convert Corzan® CPVC into high performance piping systems, ducting, tower packings, sheets and lining.