Keep Up With Membrane Technology Advances | Corzan CPVC

Membrane technology continues to advance at a lightning pace. A type of separation process, membrane technology, is being utilized in processes as varied as absorption, distillation, fouling, microfiltration, nanofiltration, reverse osmosis, ultrafiltration, and desalination. And as the technology advances, so does the dependence on piping systems to maintain fluid stream purity.

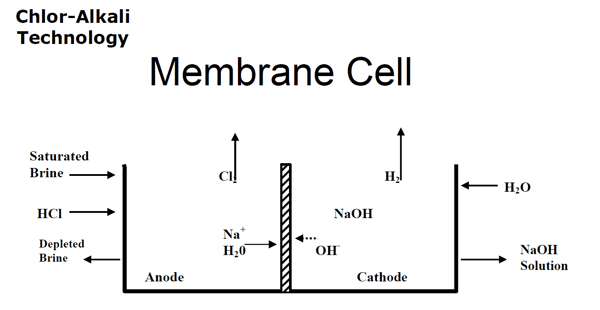

We see a particular emphasis on this in the Chlor-alkali industry, which produces the products that are used extensively in more than half of all industrial chemical processes today. Here membrane cell technology is used in the electrolysis process, where an electric current generates a desired chemical reaction – thus converting saltwater or brine into available chlorine, hydrogen potassium hydroxide, and sodium hydroxide. Charge-sensitive membrane cells are designed to allow only positive ions to pass through. Still, they are sensitive to fouling and contaminants – ions of minerals such as calcium, magnesium, silicon, nickel, lead, or tin that leach out of piping or other system components as a result of process chemical reactions.

When contamination occurs, the results can include:

- Decrease in unit efficiency

- Compromise to the integrity of the process, threatening on-spec production

- Overall reduction in system service life.

Thus, a high-efficiency process loses its technological edge because it is fouled with unwanted elemental contaminants.

Achieving Chemical Processing Purity

But the value to the industrial sector doesn’t stop with the saturated brine system of membrane Chlor-alkali production. Membrane technology has seen success in several other applications such as deionized water, process water, hydrochloric acid, sodium hypochlorite, and sulfuric acid, where it is imperative to put into the process only what should be there and no more.

The secret to keeping a process clean is to ensure that systems are comprised of components that are non-reactive to the given medium. What is considered purity in one operation could be quite different in another. Thus, it is essential to understand how piping materials in these systems are liable to interact with the process in undesirable ways, both in normal operations as well as in upset conditions.

Typical piping material choices range from carbon steel and stainless steel to piping that is fiber-reinforced glass- or PTFE-lined. A variety of expensive exotic alloys are also sometimes used. But some of these materials can be vulnerable to leaching in the presence of specific chemical reactions, diminishing the impact of advancements in the membrane technology itself because the piping systems are not chemically inert.

When Chemicals Are Reacting, Chemically Inert Corzan Offers Advantages

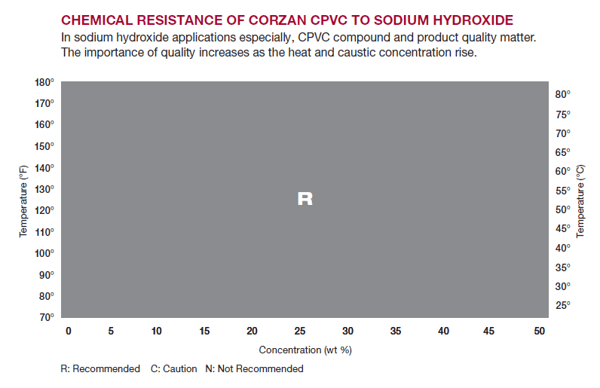

Thermoplastics have been utilized as well, but the most cost-effective and consistently reliable thermoplastic has been Corzan® CPVC technology, serving as an inert chemical resistance layer that helps protect the cleanliness of the stream from acids, bases, and salts that should not be there. Corzan CPVC pipe, fittings ducting, sheet, and valves are inherently suitable for chemical reaction processes where stream purity matters, offering superior resistance to the chemicals commonly found in these harsh applications. Corzan CPVC has been utilized in piping systems, storage or conversion tanks, headers, manifolds, and absorption towers, just to name a few applications.

Lubrizol Advanced Materials is committed to enabling a sustainable world. Our unmatched science unlocks immense possibilities at the molecular level, driving sustainability and measurable results on our mission to help the world Move Cleaner, Create Smarter, and Live Better. Join us in our work as we continue to create solutions with our manufacturing partners. For testing results or consultation, please reach out to our subject matter experts at info.corzan@lubrizol.com.