Flanging can be used to provide temporary disassembly of a piping system or can be used when it is not possible to make solvent cemented joints at the assembly site. Flanges are joined to the pipe by solvent cement or threaded joints.

Refer to the sections on solvent cementing or threading of Corzan® pipe for the proper techniques.

Flanged joints incorporate an elastomeric gasket between the mating faces to provide a seal. The gasket selected must be full-faced and have a hardness of 55-80 durometer A. Typically, gaskets are 1/8 in. thick and the material must be resistant to the chemical environment it will be exposed to and chemically compatible with CPVC.

Manufacturers of gasket materials should supply this kind of information. Keep in mind that if the piping system is for potable water service, the gasket must also be approved for potable water.

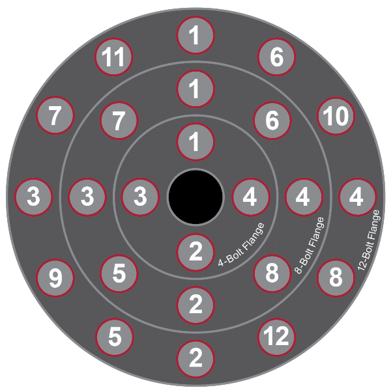

The flanges should be carefully aligned and the bolts inserted through matching holes. Use a flat washer beneath each nut and bolt head. Each bolt should be partially tightened in the alternating sequence as indicated in the patterns below. A torque wrench should be used for the final tightening of the bolts.

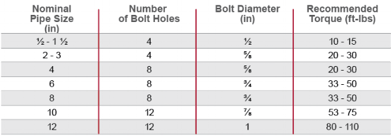

Tighten the bolts to the torque recommended in the table below in the same alternating sequence used previously.

Flange Bolt Tightening Patterns

Flange joints are typically rated to 150 psi at 73°F (22.8°C). For systems operating at higher temperatures, the flange pressure rating should be derated per the manufacturer’s recommendations.

Recommended Bolt Torque