How to Reduce Material Abrasion in Mineral Processing Pipes

In mineral processing, it’s common for solids to exist in a piping system fluid stream. However, when rocks, sand, minerals or other inorganic compounds in a slurry rub up against the inside of a pipe, material loss can occur. The risk is greatest at the pipe elbows where momentum changes occur.

As a piping system’s wall thickness is worn away, the pipe’s pressure rating and overall mechanical integrity can decrease, potentially leading to pipe leaks or failure.

How quickly a piping material wears away is contingent on two things, the fluid flowing through it and its abrasion resistance. Abrasion resistance is the ability of a material to resist material loss when another material is rubbed against it. Due to the molecular makeup of each material, some withstand wear better than others.

To reduce abrasion and preserve pipe quality, look to optimize both system conditions and piping materials. Here’s how.

Ideal System Conditions to Minimize Abrasion

All piping systems exhibit some degree of wear over time. However, particle size, shape, hardness, concentration, density and velocity in specific combinations can expedite this erosion.

To minimize abrasion, the optimal system conditions should include:

- Lower velocities. Target a fluid velocity less than five feet per second.

- Large, round particles. With their concentrated impact, smaller, sharper particles are more likely to gouge the pipe. Compare it to rubbing pebbles or sandpaper against a piece of wood; the sandpaper will cause more damage.

- Uniform particle distribution. Ideally fluid particles are roughly the same size rather than a combination of large and small particles.

- Minimum changes in direction. Increased bend radii in your pipe can result in more gradual direction and momentum changes. This reduces the force concentration on one part of a pipe’s elbow. Large-radius elbow and capped tee bends are ideal for easing into direction changes.

If you are unable to optimize the above conditions to reduce erosion, your choice in piping material becomes more important.

How Piping Abrasion Resistance is Measured

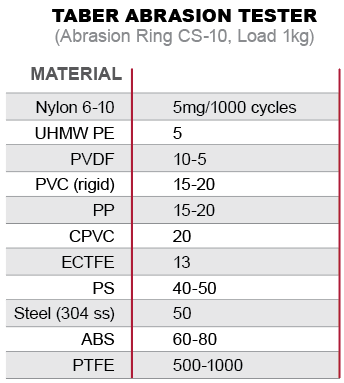

Every piping material is given an abrasion resistance value. This value is commonly defined by the Taber Abrasion Test.

During this test, a material specimen is exposed to an abrasive wheel for 1,000 cycles. The wheel rotates at a set speed, applying a controlled amount of pressure and grit. The sample is weighed before and after the cycles. The resulting weight loss gives you the material’s abrasion resistance value. Less weight loss correlates to better abrasion resistance.

Below are some common piping materials and their associated Taber Abrasion results.

The following industry standards govern abrasion testing of plastics:

- ISO 9352 Plastics: Method to ascertain plastic resistance with an abrasive wheel.

- DIN 53754: Plastic abrasion determination with the abrasive disk method.

Pipe Material Selection

Abrasion resistance scores from the Taber Abrasion Test provide a good starting point for material comparisons, but it is one of many factors to consider when building a mineral processing piping system. If you have questions about mining processing piping material, our team of product and engineering specialists is available for a free consultation.