What Is The Difference Between CPVC and PVC?

Polyvinyl chloride (PVC) is a familiar and versatile thermoplastic especially known as a piping and fitting material used for residential and commercial plumbing applications.

In the same thermoplastic family to PVC is chlorinated polyvinyl chloride (CPVC).

CPVC, though similar to PVC in name and available product types, exhibits superior resistance to heat and pressure, which enables it to be used in more demanding industrial applications.

The difference in heat and pressure resistance stem from the molecular makeup of each material.

Molecular Makeup of CPVC and PVC

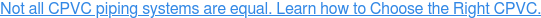

CPVC is a PVC homopolymer that has been subjected to a chlorination reaction. Typically, the chlorine and PVC react through a basic free radical mechanism, which can be initiated by thermal and/or UV energy.

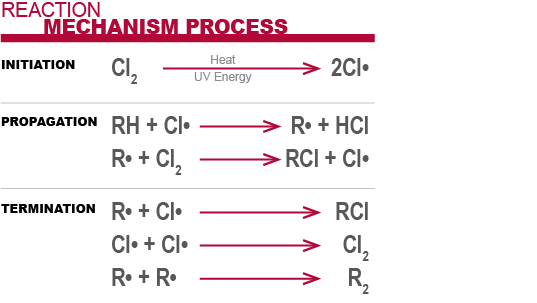

In PVC, a chlorine atom occupies 25 percent of the bonding sites on the carbon backbone, and the remaining sites are filled by hydrogen.

CPVC differs from PVC in that approximately 40 percent of the bonding sites on the backbone are filled with chlorine atoms. The chlorine atoms surrounding the carbon backbone of CPVC are large enough to protect its carbon chain from conditions that often weaken other thermoplastics.

The chlorine content of base PVC can be increased from 56.7 mass percent to as high as 74 mass percent, though typically most commercial CPVC resins contain 63 to 69 mass percent chlorine.

Diagram of CPVC (left) at a molecular level compared to PVC (right). The red spheres represent chlorine elements.

Performance Properties: CPVC vs. PVC

Many important characteristics of CPVC and PVC are consistent between the materials. And in other ways, primarily temperature and pressure resistance, the molecular differences of CPVC make its baseline characteristics superior to PVC.

Chemical Resistance

Thermoplastics are growing in popularity, often as an alternative to traditional metal materials. The PVC market, for instance, which was valued at $57 billion in 2015, is expected to reach nearly $79 billion by 2021.

Unlike metals, which are susceptible to corrosion, scaling and pitting, PVC and CPVC are inherently inert to most acids, bases and salts, as well as aliphatic hydrocarbons. This can extend their service life often for years or decades longer. Chemical resistance is a clear advantage for both CPVC and PVC.

Though, due to the difference in chlorine content, each material has a niche advantage. One example is with higher concentrations of sulfuric acid. Assuming the material is expertly manufactured, CPVC is superior to PVC. Alternatively, a chemical like ammonia is highly reactive with chlorine. The increased chlorine content of CPVC means PVC actually performs better against ammonia and most amines.

Before specifying CPVC, consult a chemical compatibility chart and contact technical support to ensure it is suitable for your application.

This chart shows the chemical resistance of CPVC for use with different chemical groups. For Corzan® CPVC’s chemical compatibility with more 400 chemicals, see the Corzan CPVC Chemical Resistance Data.

Temperature Resistance

The glass transition temperature (Tg) rises as the chlorine content in CPVC is increased. The Tg is the point where the polymer transitions from a hard, glassy material to a soft, rubbery substance, losing its structural integrity.

CPVC’s superior temperature resistance is exhibited in the ASTM standards for each material, as the maximum service temperature for PVC is up to 140°F (60°C) and for CPVC it is up to 200°F (93.3°C). Note: Be sure to check with the manufacturer to check their product’s individual operating capabilities.

Not only can CPVC be used above the maximum service temperature of PVC, but its increased temperature resistance enables it to perform better at temperatures within PVC’s working range. For example, even below 140°F (60°C), CPVC is superior to PVC in terms of impact strength and tensile strength.

Pressure Resistance

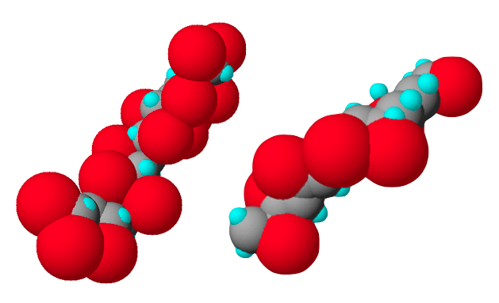

CPVC and PVC piping test to the same pressure rating at 73°F (22.8°C), but as the temperature increases, CPVC maintains its pressure rating better than PVC.

For example, let’s calculate the pressure rating for 10 in. Schedule 80 piping at 130°F (54.4°C) for both PVC and CPVC. Note that each material is pressure rated to 230 psi at 73°F (22.8°C).

- PVC has a derating factor of 0.31 at 130°F (54.4°C), making it pressure rated up to 71.3 psi at that temperature (230 psi x 0.31 = 71.3 psi).

- CPVC has a derating factor of 0.57 at 130°F (54.4°C), making it pressure rated up to 131.1 psi at that temperature (230 psi x 0.57 = 131.1 psi).

While PVC can still be specified for applications at 130°F (54.4°C), the material can withstand significantly less pressure at elevated temperatures (those above 73°F or 22.8°C) than CPVC.

This chart shows that CPVC upholds a higher pressure rating than PVC as temperature increases. Above 140°F (60°C), PVC is beyond its maximum working temperature.

Fire Performance

Thermoplastics, such as polypropylene and polyethylene, often give all thermoplastics a negative reputation when it comes to fire performance. However, susceptibility to burning and melting is not true of all thermoplastics.

Industrial CPVC, specifically, is engineered to limit flammability and smoke production. Specifically, there are ASTM tests that measure a material's:

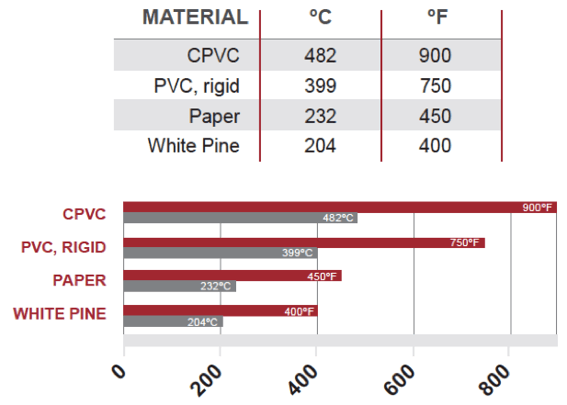

Flash Ignition Temperature: The lowest temperature at which sufficient combustible gas can be ignited by a small external flame. Corzan CPVC must be at 900°F (482°C) for this to occur, and rigid PVC must be 750°F (399°C).

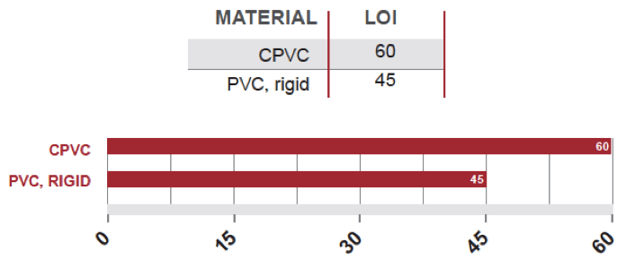

Limiting Oxygen Index (LOI): The percentage of oxygen needed in the surrounding atmosphere to sustain a flame. Corzan CPVC’s LOI is 60 and PVC’s is 45. For reference, Earth’s atmosphere is 21% oxygen.

Common CPVC and PVC Product Types

Both PVC and CPVC resin begin in either a powder or pellet form, often with the additives already blended in. The resin is then shaped or molded into the products used for residential, commercial and industrial use.

Two main molding methods are used for PVC and CPVC.

- Injection Molding: For large volume production, injection molding is an easily repeatable process. The resin is fed into a heated barrel, injected from that entry point through the mold tool, and then cooled to harden.

- Extrusion: Also a process for high volume products, extrusion begins when the resin is fed in at the top of the machine. The raw material is gradually melted through the mechanical energy of a turning screw and by heaters along the barrel. It is then formed into a continuous profile and cooled to harden.

Pipe, Fittings and Valves: A 2016 PVC market report found that pipes and fittings make up 62% of PVC revenue. The ease of installation and corrosion resistance makes it a valuable replacement to alternative materials. CPVC is commonly specified as pipe, fittings and valves where heat, pressure and chemical resistance are concerns.

Ducting: With increasing air emission regulations, the need for reliable fume handling systems, especially in corrosive environments, is growing rapidly. Depending on the demands, primarily temperature, both PVC and CPVC are specified where dependability is needed.

Sheet and Lining: The excellent corrosion resistance and fire performance of CPVC can be applied to various industrial applications and be overwrapped with Fiber Reinforced Plastic (FRP). And, when the sheet or liner will face less temperature and pressure demands, PVC can be specified.

Other product types: Often starting with CPVC or PVC sheet as a base, fabricators can cut and form the material for use in a number of varying applications.

Applications of PVC and CPVC

The value of PVC and CPVC is in their versatility, relative cost, ease of installation and corrosion resistance. Keeping those advantages in mind, common uses for each differ depending on the demands of the application.

Uses of PVC

PVC is a low cost, reliable material that can also be installed without the use of skilled, expensive welders. Globally, more than 50% of PVC resin is manufactured for use in construction.

Water: The relative corrosion resistance and low cost makes PVC the popular choice in low temperature and pressure plumbing applications.

- Drinking water

- Storm sewers

- Sanitary sewers

- Drainage

Housing: PVC sheet can be fabricated to replace other materials, such as wood, as a lightweight, sturdy substitute. The material is often painted or finished to give the appearance of other traditional materials.

- Vinyl siding

- Window frames

- Window sills

- Cabinet finishes

- Flooring

Electric cable insulation: Plasticizers can make PVC softer and more flexible for use as cable insulation. Additionally, PVC is resistant to fire and inexpensive.

Signage: Because PVC can be economical, relatively durable and easily painted, sheets of this material are commonly used for signage.

Uses of CPVC

Since CPVC builds on the strengths of PVC, it can be used in many of the same applications, but can be cost prohibitive with inexpensive PVC as a viable alternative.

However, when an application requires the chemical resistance of a PVC or CPVC, with demanding temperature and pressure conditions, CPVC is the reliable option.

Industrial Applications: CPVC is a problem-free, long-lasting solution for the harshest industrial environments, and is often specified in a number of demanding industries.

- Chemical Processing: Reliably transport aggressive chemicals at high temperatures, under pressure, without corrosion concerns.

- Chlor Alkali: Transport chemicals through some of the most corrosive environments imaginable without corrosion concerns.

- Mineral Processing: Withstand the demands of precious and raw material processing operations.

- Power Generation: Stand up long term to the high pressures and corrosive chemicals commonly used by power plants.

- Semiconductor: Flame and smoke resistance that increases efficiency, enhances safety, and prevents contamination in cleanrooms.

- Wastewater Treatment: Put an end to corrosion, even when transporting the most aggressive disinfection chemicals.

Residential and Commercial Plumbing: For plumbing applications that require more temperature and pressure reliability, CPVC provides a safe, efficient and flexible system resistant to scaling, pitting, and bacteria buildup—regardless of the water pH or chlorine levels.

- Hospitality: Restaurants and low-rise office buildings.

- Retail: Mid-rise office buildings and shopping malls.

- Education: K-12 schools, as well as colleges and universities.

- Healthcare: Hospitals, medical clinics and medical complexes.

- Multi-Family: Structures six stories or less, including apartments, condos, hotels and motels.

- High-Rise: Apartments, condos and hotels that span seven stories or more.

Residential and Commercial Fire Sprinklers: The flame and smoke resistance of CPVC, along with its simple joining method, make it ideal for different housing applications.

- Single family (NFPA 13D): Standalone housing, mobile homes.

- Residential (NFPA 13R): Structures of four stories and less, including condos, hotels or motels, and multi-unit apartment buildings.

- Commercial Residential (NFPA 13): Structures of five stories and more, including high-rises, condos, hotels, and multi-unit buildings.

How Does CPVC Compare to Metal Piping Materials?

For certain applications, PVC and CPVC are commonly specified to replace metal. Check out our resource article, Metal v. CPVC Piping Systems, to learn more about how CPVC stands up to metal alternatives.