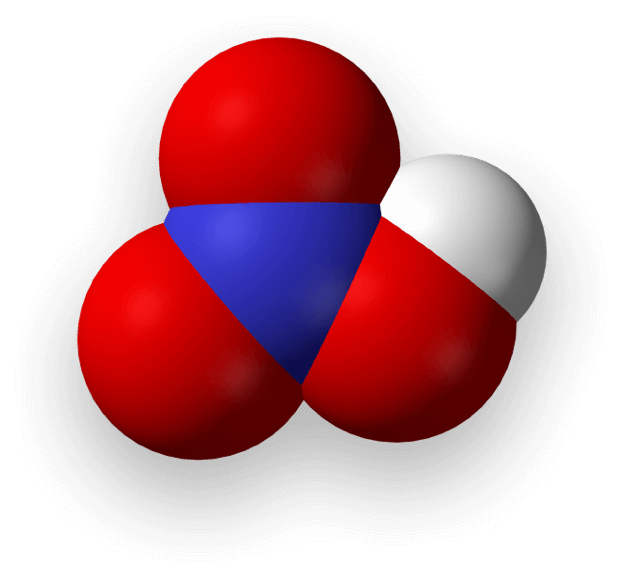

Why CPVC Works Well With Nitric Acid

High-quality CPVC like Corzan® CPVC has a high level of chlorine on the polymer chain. This protects the CPVC from the degrading effects of highly corrosive acids commonly used by industrial plants for everything from the purification of metals to the manufacture of other important industrial chemicals. Corzan CPVC has excellent resistance to nitric acid due to its superior engineering and formulation.

CPVC resists material degradation and corrosion far better than metals, but these still can occur over time. The severity of both general degradation and localized stress cracking is often contingent on temperature, pressure, acid concentration, strain applied to the material, manufacturing quality, fabrication quality and the quality of the CPVC compound. While nitric acid may cause whiting on the material surface, degradation caused by nitric acid comes in the form of tensile strength reduction.