Why CPVC Works Well With Sodium Chloride

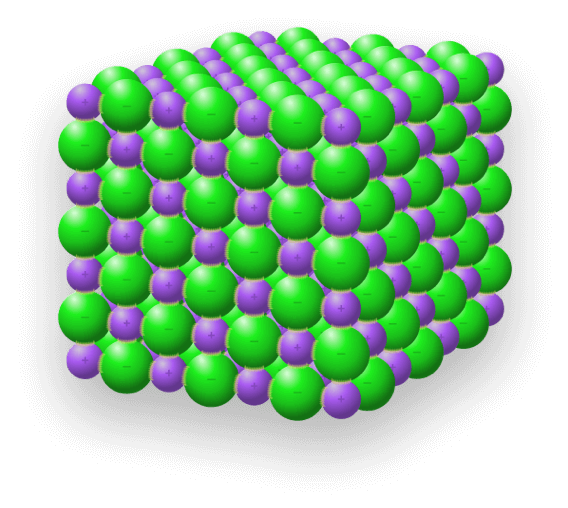

All plastics are inherently resistant to all salts because floating ions pass directly over plastic materials without the negative effects metals will experience. High-quality CPVC like Corzan® CPVC is suitable for use at much higher temperatures than other plastics and lower-quality CPVC in industrial applications including food processing and plastic-making.