What Is Life Cycle Assessment and How Do Pipes Play a Role?

When designing a sustainable building, topics such as energy efficiency and indoor air quality are often top of mind. But just as important is the consideration of resource efficiency and the sustainability of the components that make up the building—and the components that make up those components.

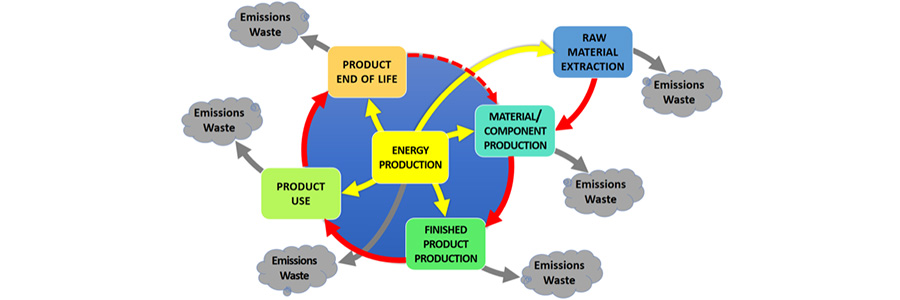

Life cycle analysis provides a complete look at the environmental impacts of a product or system from raw material extraction through production, use, and, finally, end of life. By including the use phase of a product’s life into this analysis, one can make specific comparisons based on a product’s application. It is a time-consuming process for raw material producers and manufacturers, but it enables environmental impacts to be weighed among products of similar applications. In other words, it allows product specifiers to make apples-to-apples comparisons of products, weighing the environmental or human health attributes of one product clearly and legitimately against another in order to select the material most in line with chief project goals.

The onus of these analyses is on the material producers and product manufacturers. As their knowledge of life cycle impacts grows, they will be able to improve the sustainability of their processes, products, and supply chains. The U.S. Green Building Council is encouraging this through LEED v4, where new credits and pilot credits reward product transparency.

Lubrizol recently completed a life cycle assessment for FlowGuard piping systems globally, including Corzan piping systems for commercial plumbing applications in North America. The result is a baseline report that assesses the cradle-to-grave environmental impacts of the system, including the raw materials, manufacturing, transportation, use, and end of life stages. The evaluation was conducted by third-party agency ERM and peer reviewed by Dr. Walter Klöppfer, editor-in-chief of the International Journal of Life Cycle Assessment.

The LCA, which conforms to ISO 14040 and 14044 Standards, outlines the environmental impacts of the piping systems compared to other materials.

Based on the FlowGuard Gold LCA, Environmental Resource Management (ERM) wrote a report comparing FlowGuard environmental impacts to those of copper. The cradle-to-gate comparison, which analyzed impacts through the production of pipe, showed a significant benefit in choosing FlowGuard Gold products. For example, FlowGuard CPVC was found to have a lower global warming potential (carbon footprint) than copper.

To learn more about Corzan Material and Piping Solutions’ role in sustainable buildings, download our white paper.