Temperature Control and Corzan® CPVC Installation

Like any material, Corzan® CPVC is affected by extreme temperatures – though much less than metallic alternatives. Take temperature extremes into account when solvent welding, as high and low temperatures affect cure times.

Thermal Expansion and Contraction

Corzan CPVC piping has a low coefficient of thermal expansion among the family of thermoplastic piping materials. However, its thermal expansion is still greater than that of metal piping.

Typically, expansion loops or offsets in the piping are designed to account for any thermal expansion or contraction. Expansion joints can also be installed. Information on expansion joints can be obtained by contacting Lubrizol or Corzan Piping Systems’ partner manufacturers. To account for expansion and contraction in design, check out our thermal expansion calculator.

Insulation

While Corzan CPVC and other plastic piping materials have much lower thermal conductivity compared to steel and copper, the material alone is not always sufficiently insulating to meet the minimum required thermal performance needed for code compliance for pipe in commercial plumbing and hydronic HVAC.

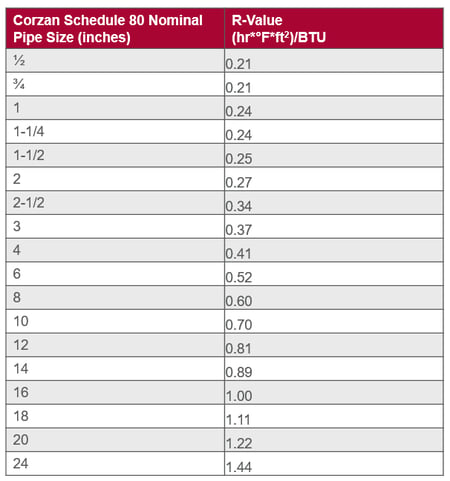

Some codes may afford designers the flexibility to use plastic pipes with thicker walls at reduced levels of insulation. But, in general, code officials will require alternative designs to demonstrate parity of thermal performance with a baseline case that meets code. Engineers can run their own calculations based on the table below to determine how much insulation to use:

Also consider worker safety when determining hot water service insulation. The Uniform Mechanical Code, Section:1201.2 (2015) requires pipe insulation with a surface temperature of 140°F or higher to prevent skin burns. The exterior surface temperature of metal pipes will be roughly equal to the temperature of the water being conveyed due to metal’s high thermal conductivity, while the temperature of Corzan CPVC piping will be considerably lower.

For instances of system piping that is not being driven by a plumbing, mechanical or energy code (e.g., hot- and cold-water supply lines within conditioned buildings), insulation may not be needed, or could be reduced, because Corzan CPVC piping will remain condensation-free under most environmental conditions that would cause copper tube to sweat and drip. Water temperature can be calculated versus the dewpoint to determine the best solution. Perform a full evaluation of the system requirements including meeting applicable energy codes governing heat loss, as well as determining the pipe’s operating surface temperature for hot water service and the potential for condensation for cold water service.

Get Customized Training on Installing Corzan CPVC

We know every project made with Corzan CPVC is unique. Fill out the form to discuss and schedule customized training.

Submit the form and an expert will be in touch within one business day.