Dimensions and Weights for Specifying Corzan® CPVC

Any system should be designed in accordance with the manufacturer’s instructions and any compliance standards. Manufacturers’ specification sheets offer insight into a material’s pressure and flow requirements, friction loss, operating temperatures, support spacing, anchoring, bracing and thrust blocking, joining methods, thermal expansion and contraction and more.

Dimensions and Weights

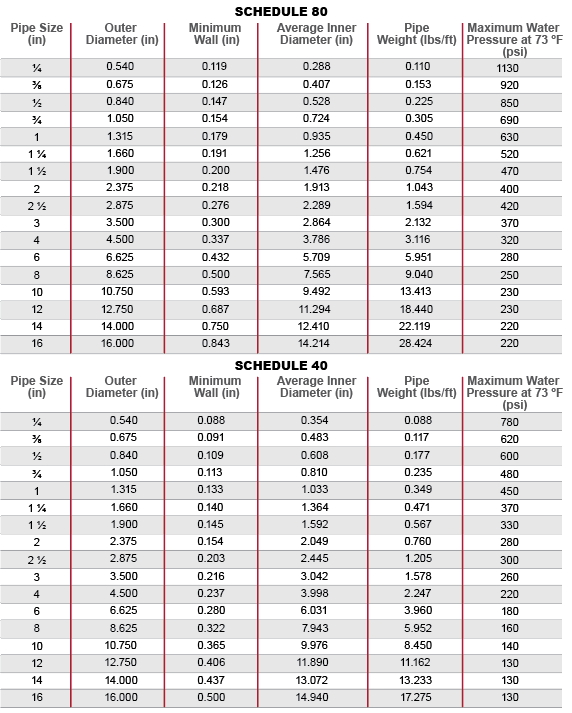

Corzan® CPVC pipe and fittings are available in Schedule 40 and 80 iron pipe size (IPS) dimensions from 1/4-inch. through 24-inch. Pipe size typically dictates how much CPVC pipe weighs per foot. Schedule 80 1/4-inch pipe, for example, weights 0.110 lbs/ft, while Schedule 40 10-inch pipe weighs 13.413 lbs/ft. Dimensions and weights for Schedule 40 and Schedule 80 piping variations are shown below:

Definitions and Derivations

Piping design engineers can use the data above to estimate loads, stresses, torques, and other mechanical data. Following variables and equations can be used to define these values.

t: Minimum wall thickness of the pipe in inches as specified by ASTM F441 - Standard Specification for Chlorinated Polyvinyl Chloride (CPVC) Plastic Pipe, Schedules 40 and 80.

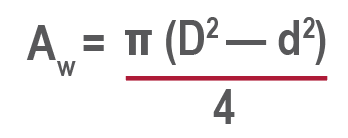

Aw: Cross-sectional area of the pipe wall in square inches.

D: Outside diameter of the pipe in inches as specified by ASTM F441.

Af: Cross-sectional area of flow in pipe in square inches.

d: Average inside diameter of the pipe in inches calculated by considering theaverage wall thickness to be the minimum wall thickness plus half the tolerance allowed by ASTM F441. All the values in the above tables are calculated with the average inside diameter, not the minimum wall thickness.

W: Average weight of pipe, in pounds per foot.

Ao: Outside surface area of the pipe in square feet per foot.

Ww: Average weight of water in pipe, in pounds per foot.

Ai: Inside surface area of the pipe in square feet per foot.

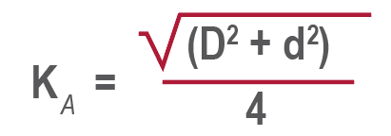

KA: Radius of gyration about the longitudinal axis of the pipe, in inches.

IA: Moment of inertia, in inches to the fourth power, (in4).