Corzan® CPVC Ducting Installation Guidelines

Proper installation of products made with Corzan® CPVC is critical to the performance of the system. Ensure long service life and safe operation with proper installation practices, including use of hangers and spacing.

Corzan® CPVC ducting can be easily assembled in the field using standard thermoplastic pipe joining techniques. The most common methods involve solvent cementing or thermal hot air welding. Both methods provide reliable, cost-effective joints. Other methods of joining and fabricating Corzan CPVC ducting and system accessories include thermoforming, extrusion welding and hot-plate welding.

Solvent Cement Welding

Belled end duct, couplings, flanges and other socket-style fittings can be joined using the solvent cementing process. Solvent cement welding has been used successfully for more than 50 years in tough, corrosive, high-pressure applications. When properly conducted, this method provides a strong, homogeneously joined area in which the mating surfaces are chemically fused together, producing a strong, leak tight seal when cured.

Adequate surface-to-surface contact of the parts being joined is necessary for reliable solvent cemented joints. Generally, a minimum socket depth of 3 inches for any size ducting will provide sufficient joint strength for most systems.

Since duct dimensional tolerances can vary when compared to heavy wall pipe, the use of extra heavy-bodied CPVC cement (such as IPS 3461 or equivalent) is recommended due to the cement’s excellent gap-filling properties. Care should be used when solvent cementing duct diameters 18 in. and larger to ensure tightness of fit of mating components. The solvent cementing method is not recommended for any type of end-to-end joining. Get details on solvent cement welding Corzan CPVC here.

Thermal Welding

Hot air welding uses clean, hot air to preheat the duct material and CPVC welding rod, while pressure is applied to the weld area as the rod is guided along the mating surface areas. This joining method results in the parts’ surface molecules fusing together at the weld seam.

Only welding rod produced from Corzan CPVC material is recommended for this joining process to ensure the highest system integrity. All welding should be conducted by personnel adequately trained in the art of hot air welding of thermoplastics. Get details on thermal welding Corzan CPVC.

Flanged Systems

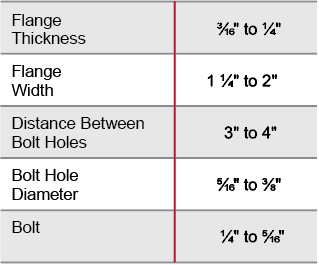

For flanged systems, the general recommendations for flange fabrication are:

Get Customized Training on Installing Ducting Made with Corzan CPVC

We know every project made with Corzan CPVC is unique. Fill out the form to discuss and schedule customized training.

Submit the form and an expert will be in touch within one business day.