The Value Drivers of Lightweight Pipe in HVAC Projects

Thermoplastic Corzan® CPVC pipe and fittings are designed to meet the temperature and pressure requirements of HVAC applications and withstand the internal stresses that result from conveying fluids over time at various operating temperatures, up to 180°F, in these complex projects.

When exposed to the same chemicals that can degrade and reduce the service life of many metallic materials, a properly installed Corzan Piping System merely handles the exposure as part of its regular duty because its smooth surfaces are resistant to corrosion. This is doubly important when the system is exposed to atmospheric conditions that could further accelerate corrosion. It can also accommodate wide swings in pH in the fluids it comes in contact with, never pitting or scaling. In fact, Corzan CPVC has been used for decades in industrial process water applications handling chilled and boiler water treated with corrosion inhibitors, biocides, and other types of treatment chemicals similar to those used for recirculating HVAC systems.

As a result, HVAC pipe can be designed for flow without compensating for corrosion and scale buildup. Hydraulic calculations for sizing pipe and fittings should incorporate a Hazen-Williams C factor of 150, which will remain constant as the system ages because pressure drops from friction will be minimized.

Typical Corzan CPVC Advantages Over Metal in HVAC Projects

Working with Corzan CPVC piping can alleviate other concerns as well. Consider that with metal piping systems comes:

- Specialized welding techniques and the associated fire risks

- Added time and electrical requirements for welding, soldering and threading

- More limitations on where the pipe can be run based on the weight-bearing capabilities of the different parts of a building, such as roof loads

- Difficulty in making course corrections at the jobsite if needed

Each of these vanishes from the equation with Corzan CPVC piping. CPVC can be prefabricated if desired, but onsite fabrication is just as feasible and requires only handheld tools for cutting and preparing the pipe and fittings for the simple two-step solvent cement process. In some applications, Corzan CPVC can be joined using a system of cutting and grooving the pipe, then connecting the sections with specialty fittings, requiring minimal electric power.

How Lightweight Piping Brings Further Benefits

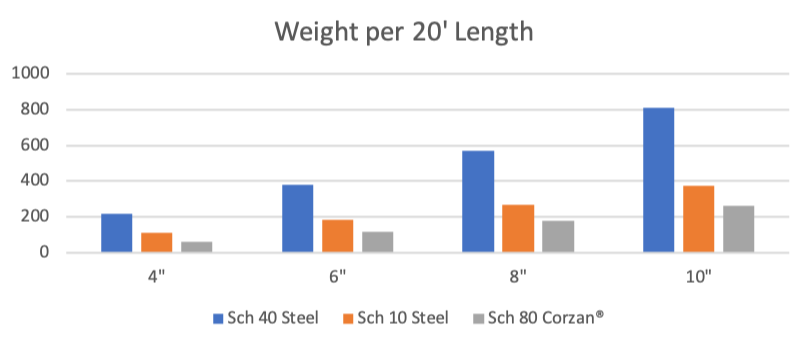

A key value driver of CPVC in HVAC projects is weight, as the material is always lighter than comparably sized steel, giving it an undeniable edge in maneuverability. Compare the weight differences among 20-foot pipe lengths for 4-to-10-inch Sch. 80 Corzan CPVC with the steel equivalents below:

Thus, working with a lightweight material lowers the likelihood of strain and injury during installation, especially when workers must contort themselves to run the pipe in the designated space. But it also reduces the expense of (1) heavy lift machinery to transport and hoist the piping into position and (2) more than one worker to move the piping. For example, two workers can safely carry a 20-foot, 4-inch stick of Corzan CPVC without the aid of machinery or lift systems.

Construction business owners know the potential for workers to be injured on a job – with its lost time and many other associated costs – is a generally accepted business risk.

Yet the backbone of every construction operation is a healthy crew with strong backs, not a group of laborers on the disabled list. For plumbing and mechanical contractors installing HVAC systems, the ability to minimize incidences of back and shoulder injuries and musculoskeletal problems can be directly tied to reducing the lifting height of piping materials.

Even if it is never recognized in a project cost in any way other than a disrupted timeline, an injury-plagued workforce is a real cost among others in a total-cost analysis. So while there may only be minimal cost advantages to using larger diameter Corzan CPVC pipe compared to imported steel, even with possible tariffs, maybe you can start to make the case that long-term benefits of working with a lightweight material do justify the cost, not only for your business, but for your customers.