Corzan CPVC and Thermal Conductivity: Important Considerations

Thermal conductivity is an important consideration in any piping application, from both a safety and liability perspective. A piping system material with lower thermal conductivity will maintain a lower surface temperature when transporting hot fluids. In certain situations, this can reduce the risk of burns to operators who may come in contact with the pipe.

This is especially pertinent for individuals working near a valve, pump, or tank inlet, where multiple piping runs exist in close proximity. According to the Bureau of Labor Statistics, instances of thermal heat burns caused a median of 6 days away from work in 2016.

To achieve a comprehensive picture of CPVC’s thermal conductivity qualities, Corzan® Industrial System engineers recommend starting with a comparison of thermal conductivity ratings.

Thermal Conductivity Ratings

The standard for evaluating the thermal conductivity of a material is ASTM C177, “Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus.” This is a controlled method for measuring the transfer of heat through a material.

CPVC exhibits exceptionally low thermal conductivity—approximately 1/300th that of steel. This is due to differences in the atomic arrangement of the materials.

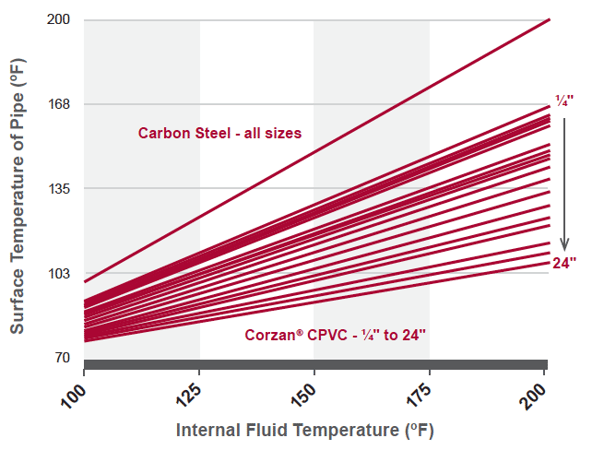

The plot below helps illustrate this point. It shows the surface temperature of a pipe in relation to the internal fluid temperature. Items of note include:

- The surface temperature of carbon steel piping is the same as the internal fluid temperature, whereas CPVC pipe surfaces maintain a much cooler temperature.

- The surface temperature of carbon steel is practically the same as the fluid temperature regardless of its wall thickness. Conversely, the wall thickness of CPVC pipe affects its surface temperature because it exhibits much higher thermal resistance than steel. Wall thickness is dependent on the pipe schedule and size.

Estimated Pipe Surface Temperature vs. Internal Fluid Temperature

*Note: Plot assumes ambient temperature of 68°F (20°C) and water flow at 6.5 ft./sec. (2 m/s)

Regardless of material, certain industrial applications will increase a pipe’s surface temperature to unsafe levels. In these situations, insulation must be considered.

Piping Insulation Needs

A benefit of a piping material’s low thermal conductivity is that less insulation may be required to keep the pipes’ temperature consistent. This is true whether the ultimate goal is to protect against a pipe’s external temperature or to maintain a constant temperature within the pipe.

Understanding a pipes maximum surface temperature is important for worker safety. As demonstrated above, the surface temperature of the pipe varies with the type of pipe in service for a given process. Regardless of the piping material, insulation might be needed to protect workers from burn hazards when working around the piping system. Knowing the surface temperature of the pipe will help to identify when insulation is needed to mitigate burn hazards.

Additionally, thermally conductive material allows heat to escape at a faster rate than materials that don’t transfer heat as well. For this reason, thermally conductive pipes in environments cooler than the fluid they’re transferring require additional energy to maintain fluid temperature. The amount of additional energy is contingent on required fluid temperature and the ambient temperature.

No matter the reason for insulation, the amount of insulation is dependent on the fluid temperature, type of pipe, and desired heat retention, and can vary from one application to the next. To determine the specifics for your piping system, discuss it with Corzan Industrial Systems’ team of experts.

Condensation

Thermal conductivity also comes into play in cold piping systems.

When handling cold fluids, the more thermally conductive a piping material, the lower its surface temperature. In the right ambient environment, where the surface temperature of the pipe is below the dew point of the environment, condensation can form and pose safety concerns.

Consider a hot and humid factory with cold lines running through it. The cold pipe surface coupled with warm temperatures and saturated air creates a perfect recipe for condensation to form on the outside of the pipes. This can result in:

- Dust and dirt on the pipes mixing with condensate and contaminating a sterile environment.

- Puddles on the floor, creating slippery surfaces.

- Dripping onto inventory or other stored items.

A less thermally conductive piping material can help avoid these situations, or at minimum, limit the need for insulation.

Curious How CPVC Piping Stacks Up Against Metal in Other Areas?

CPVC’s unique characteristics don’t stop with thermal conductivity. To learn more, read the article, “Metal v. CPVC Piping Systems: Which Piping Material Performs Better In Industrial Applications?”