CPVC Pipe Insulation Guide: Everything You Need to Know

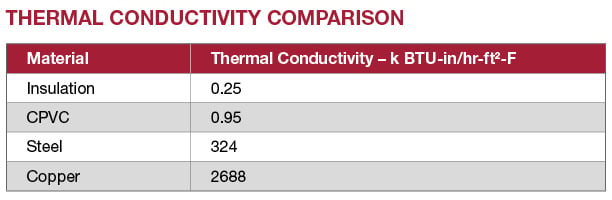

The lower thermal conductivity of CPVC and other plastic piping materials compared to steel and copper often leads specifiers to wonder whether the material alone is sufficiently insulating for pipe in commercial plumbing and hydronic heating applications. Corzan CPVC’s thermal conductivity is 1/300th that of steel, so this is a reasonable question, especially given pipe insulation’s materials and labor cost. The reality is that it depends on the application.

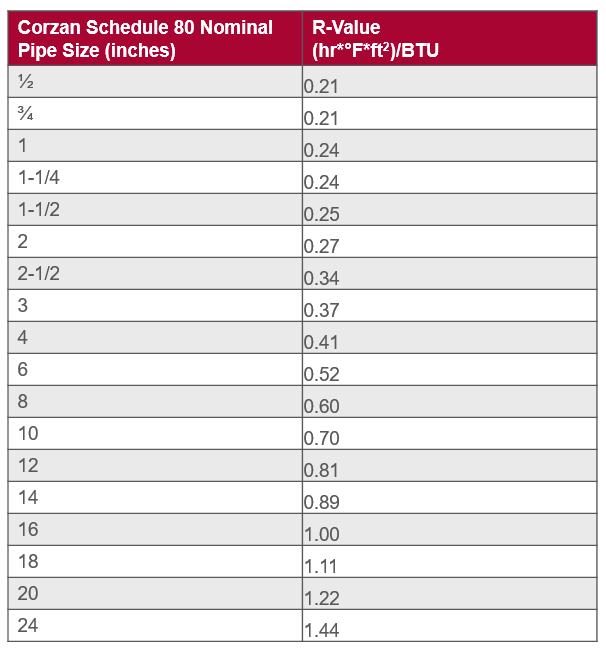

How a bare pipe loses heat is governed by (1) the inherent thermal conductivity of the pipe material (its K-value), and (2) the thermal resistance of varying pipe thicknesses (the R-value). All current model building energy codes require pipe insulation on service hot water and HVAC applications to prevent that loss. However, the codes are material-neutral; the insulation requirement is expressed in terms of minimum thickness only.

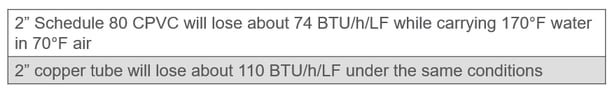

The reason? While the choice of pipe material and its thickness certainly has a bearing on the rate of heat transfer (see chart below), the effect upon thermal performance is relatively small once pipe is insulated, and does not justify reducing the pipe insulation thickness requirements from material to material.

While CPVC’s lower thermal conductivity inhibits heat loss, the material alone cannot meet the minimum required thermal performance needed for code compliance. [See Facts About Insulation Requirements for Plastic Piping, a publication of the North American Insulation Manufacturers Association (NAIMA), to read more about the subject.] Some codes may afford designers the flexibility to use plastic pipes with thicker walls at reduced levels of insulation. But, in general, code officials will require alternative designs to demonstrate parity of thermal performance with a baseline case that meets code.

In these instances, engineers can run their own calculations based on the table below to determine how much insulation to use:

A separate and important insulation consideration when dealing with hot water service pertains to worker safety. The Uniform Mechanical Code, Section:1201.2 (2015) requires pipe insulation with a surface temperature of 140 F or higher to prevent skin burns. The exterior surface temperature of metal pipes will be roughly equal to the temperature of the water being conveyed due to metal’s high thermal conductivity, while the temperature of CPVC will be considerably lower.

For instances of system piping that is not being driven by a plumbing, mechanical or energy code (e.g., hot and cold water supply lines within conditioned buildings), insulation may not be needed, or could be reduced, because CPVC will remain condensation-free under most environmental conditions that would cause copper tube to sweat and drip. Water temperature can be calculated versus the dewpoint to determine the best solution.

Above all, before specifying any piping material, a full evaluation of the system requirements in advance of making a final selection is key. Those requirements may include meeting applicable energy codes governing heat loss, as well as determining the pipe’s operating surface temperature for hot water service, and the potential for condensation for cold water service.

Have more installation questions? We’re here to help with training and support. Contact your Corzan representative today.