CPVC Pipe Joining Methods Impact Efficiency, Productivity

Industrial facilities require reliable equipment that ensures long-term performance for maximum productivity and minimal downtime. When choosing a piping system for an industrial application such as a hydrochloric acid or sodium hypochlorite facility, specifiers must consider the joining method for a piping material and how it will impact labor costs, productivity and service life.

The greatest test for any pipe joining method is whether you can trust it to hold and facilitate materials movement over the long term, even in the presence of harsh corrosive chemicals, high temperatures, pressure and impact. The question to ask is whether the pipe product and joining method have a proven history of keeping facilities operating efficiently while protecting workers against exposure to potentially hazardous chemicals?

Joining methods for non-metallic materials vs. metal

Metals have long been used in the industrial piping industry because of their availability. Metal piping, however, is heavy compared to non-metallic piping systems and must be joined by welding processes that involve cumbersome equipment and require workers to have hot work or specialized permits. Welding steel piping also has the potential to create a safety hazard as even a small leak could result in chemical exposure.

Non-metallic piping such as CPVC is joined with methods such as hot air welding, fusion welding, mechanical joining or a two-step solvent cement process, which is the preferred method for joining. Solvent cement chemically fuses the pipe to the fitting for a highly reliable joint that is the strongest part of the entire piping system and able to withstand harsh chemicals, high temperatures, pressure and impact. The strength of a CPVC solvent- cemented joint contrasts with the joints in other types of piping systems, which are often the weakest part of the system and the most likely to fail.

Video footage demonstrates the strength of a Corzan® CPVC solvent cement welded joint during a burst test conducted according to ASTM D1599 requirements. The solvent cement welded joint performs under intense internal pressure, with ASTM F441 requiring that a one-inch schedule 80 CPVC pipe withstand 2020 psi before failing. This Corzan CPVC pipe did not fail at 2900 psi, the burst unit’s limit.

Solvent cement versus glue for joining pipe

Sometimes individuals use the terms glue and solvent cement interchangeably when referring to how thermoplastic piping is joined. Although both accomplish the immediate goal to join pipes and fittings, glue is an unreliable choice for industrial piping applications as glue bonds only stick materials together, regardless of the type of adhesive. If a strong enough force impacts the glue joint, the adhered area can break the bond and the joint can come apart or fail.

Solvent cement is comprised of CPVC resin, stabilizers and fillers in a variety of solvents. These solvents dissolve the CPVC resin and prepare the surfaces of the pipe and fitting by softening the top layers of the pipe and fitting material, which loosens the molecular structure. The taper in the fitting socket creates an interference fit that ensures contact between the pipe and fitting and allows the material to fuse to itself when the two pieces are connected.

These fused joints help maintain the entire piping system’s life expectancy, high distortion temperature, pressure rating, chemical resistance and safety qualities.

Solvent cement setting and curing

Solvent cement requires about half the time to join piping and fittings compared to welding. But it must be allowed to cure as the molecules harden and the solvent flashes off. A joint is considered fully cured when the solvent has completely evaporated.

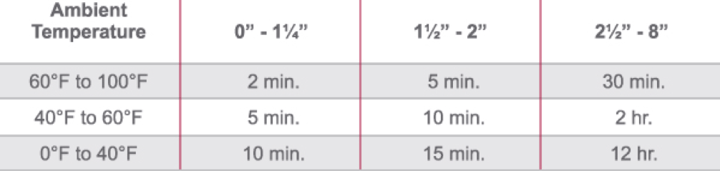

Solvent cement set and cure times depend on pipe size, temperature, relative humidity and the tightness of the fit. Less drying time is required in drier environments and with smaller pipe sizes, higher temperatures and snugger fits.

The following charts indicate the set and cure times for solvent cement, although Corzan Industrial Systems recommends checking with the solvent cement manufacturer label for recommended set and cure times.

Solvent Cement Set Times (up to 8" shown, availability up to 24" NPS)

Solvent Cement Cure Times

Proper installation for greater productivity and longer service life

Only CPVC solvent cement should be used with CPVC and bonders should be qualified according to ASME B31.3, considered the bible of process piping engineering. In-house installers can generally install CPVC and join it with solvent cement but must have the proper training as incorrectly applied solvent cement or cement used in the wrong application can cause joints to fail – and failure means exposure.

Training is available through coalitions, local union halls, local training centers and trusted companies such as Lubrizol. Corzan manufacturing partners also offer training. Corzan CPVC piping systems are available from several partners around the world.

In addition, you should always consider the compatibility of the CPVC piping system with the chemicals used in the processing facility. The Corzan CPVC Chemical Resistance Chart provides Corzan’s compatibility with over 400 chemicals.

Although solvent cementing is the preferred joining method for CPVC piping systems, other alternatives exist. If it’s necessary to connect to an existing metal pipe or if the system needs to be disassembled, the CPVC pipe can be joined via flanges or threading. Full lines of transitions, threaded connections and flanges are available through distributors – as are CPVC valves.

It is possible to create an all-CPVC system that facilitates future maintenance and provides a reliable piping system with less downtime and greater productivity during an extended service life.

Corzan Industrial Piping systems have demonstrated over 60 years of success in a wide range of industrial applications worldwide. Contact us for a free chemical resistance, process suitability and technical consultation.

Some of the details in this blog were taken from the Lubrizol Chemical Processing Piping Special Report and The Complete CPVC Solvent Cement Guide. Please reference these materials for more information.