CPVC Pipe Pressure Rating: How Is It Determined?

One of the most misunderstood aspects of CPVC pipe is how its pressure rating is calculated and what that rating really communicates to the end user. A common assumption is that the pressure rating is determined by increasing the pressure in a pipe until it bursts. The reality is that CPVC intended for use in pressure piping systems must empirically prove its pressure bearing capability in a surprisingly rigorous data collection and analysis process.

While evaluations of short-term tensile strength can be a good indicator of copper’s long-term strength, such is not the case for pressure-rated plastics. In fact, CPVC material manufacturers must be able to produce many months of data on multiple different lots to prove that their product will last 50 years. The Hydrostatic Stress Board of the Plastics Pipe Institute (PPI) governs the pressure rating of plastic pipe and fitting materials in the US. According to PPI, “The primary functions of the Hydrostatic Stress Board (HSB) of PPI are to issue recommendations to industry regarding the strength of thermoplastic piping materials intended for pressure applications, and to develop appropriate policies and procedures for the conduct of this activity.” The Hydrostatic Stress Board reviews all the data, which must be generated at a qualified laboratory, and lists recommendations for the hydrostatic design basis (HDB) for each material annually.

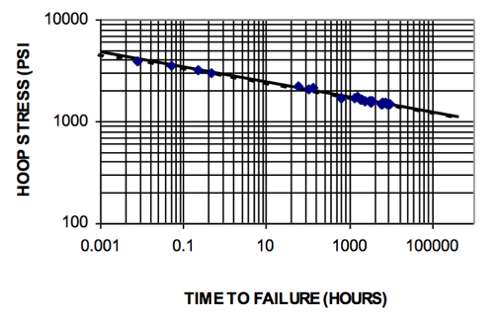

The data is generated in accordance with ASTM D1598: “Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure.” To determine the LTHS value, pipe specimens made of the material are tested at stress levels causing the pipe to rupture at time periods distributed over 10 hours to in excess of 10,000 hours. For a pressure rating at 180°F, PPI requires test data exceeding 16,000 hours. The data must be linear, presented as below and extrapolated to 100,000 hours. To ensure that the material’s performance is consistent, data is required on three separate lots of material. To ensure that commercially-produced pipe is also capable of the same performance, at least one of the submitted lots of data must be generated from samples produced by a commercial manufacturer.

CPVC’s Long Term Hydrostatic Strength (LTHS) is determined by analyzing the stress versus time-to-rupture test data in accordance with ASTM D2837: “Standard Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for Thermoplastic Pipe Products.” This standard provides the statistical method which must be used to extrapolate the data, and places requirements on the consistency and linearity of the data. It also places limits on how much the pipe is allowed to expand circumferentially during the test and how steep the slope of the line may be.

Once the data has been analyzed and determined to meet the requirements placed on it, ASTM D2837 provides range categories for the extrapolated LTHS values which define the material’s Hydrostatic Design Basis (HDB). For instance, if the material’s extrapolated LTHS value is between 960 and 1200 psi of stress, its HDB is categorized as 1000 psi. This is the typical HDB of standard grades of CPVC pipe materials. Lubrizol also offers high strength Corzan materials meeting the next higher HDB category of 1250 psi (LTHS values ranging from 1200-1530 psi). While the standard for CPVC schedule sized pipe (ASTM F441) requires that the material must have a listed HDB, the standards for CPVC schedule sized fittings (ASTM F438 and F439) do not have that requirement. However, to ensure confidence in the entire Corzan system, Lubrizol offers fitting grade materials with HDB listings.

But it doesn’t stop there. Once the HDB has been determined, a safety factor is applied to it to calculate the material’s Hydrostatic Design Stress (HDS). This is the maximum allowable pressure stress a pipe should withstand under actual service conditions. This cushion ensures that adequate material strength is reserved for potential real-world stresses that go beyond mere pressure bearing, such as those related to installation, lot-to-lot variability and chemical exposures. The safety factor used for CPVC pipe materials is 2, which means that even if the pipe is pressured to its design limit, there is 50% of the long-term material strength left over.

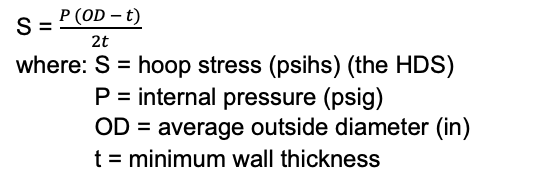

Ultimately, the pressure rating that appears on the commercial pipe is calculated by plugging the HDS into the equation below, which relates stress, dimensions and pressure.

Hoop stress is related to internal pressure and pipe dimensions by:

As you can see, there is a great deal of rigorous testing and industry oversight, as well as a generous safety factor behind the pressure rating that eventually gets printed on each piece of pipe. All of this ensures that you can be confident in the long term performance of your Corzan® CPVC piping system. As you start to consider your next project, your Corzan Piping Systems representative is available for support and training.