CPVC Replaces Steel and PVC at Delta Faucet's Largest Plant

Delta® Faucet Company’s Greensburg, Ind., plant is the largest of its three faucet manufacturing sites, with 1,150 employees producing 1,500 different products.

The engineers needed a piping material that could meet a variety of criteria:

- Corrosion resistance

- High-temperature resistance

- Resistance to acids and bases

- Meet stringent safety assurance standards

- Easy to modify and repair

Taking each requirement into account, Delta engineers specified chlorinated polyvinyl chloride (CPVC) for its metal plating operations.

We need to have a leak-free, dependable system. That is why we’re using CPVC.

James Retz, Plant Engineer at Delta's Largest Plant

“The variety and type of plating that takes place here makes it a tough environment for process components,” says Ed Browning, maintenance supervisor for Delta Faucet.

Throughout the plant, pipe fittings range from a half-inch to 12 inches in diameter, all Schedule 80 for both the pressurized and non-pressurized lines. Piping conveys four grades of water (city, soft, reverse osmosis and deionized) mixed with caustics, acids, cyanides and plating metals such as chrome, nickel, brass, copper and gold. The solutions are steam-heated to 180°F.

The Pitfalls of CPVC Alternatives

PVC: “Above a certain temperature, PVC pipes begin to sag and the joints can lose integrity,” says Retz, noting this is a condition that can precipitate leaks.

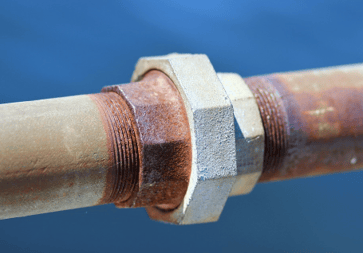

STEEL: “The pH range for the solutions is from acidic to alkaline, which is why we don’t use carbon or galvanized steel,” says Browning. “We don’t want to find any iron in our nickel baths, so we stay away from steel or ferrous metal piping. The CPVC piping has reduced product cross-contamination.”

In the nickel baths, CPVC is a better choice than a threaded steel system. “Nickel can run down the thread of a pipe,” Browning explains. “With the cemented joints of the CPVC, the nickel doesn’t do that. I don’t have to worry about thin threads or cutting threads on the pipe and then having them corrode.”

Replacing galvanized steel piping with CPVC in the plant’s water treatment area eliminated previous concerns with the galvanization coming off and plugging filters.

Corzan CPVC is Reliable

Delta’s 12-inch iron sludge transfer line also was replaced with CPVC pipe and fittings. The line, which processes up to 300,000 gallons a day, is located behind myriad other pipes and components, making it difficult to access if repairs or maintenance are needed.

The nickel filter system conveys hot nickel solution, then filters, processes and transfers fluids back into the tanks. The remaining water is treated to a level that is cleaner than it was when entering the plant. CPVC has no threads, allowing no leaks, and withstands high temperatures, preventing corrosion.

Corzan CPVC Promotes Safety

Repairs are easier with CPVC. Previously, if a section of steel pipe failed, the entire plant was pulled off-line while the section of pipe was replaced. CPVC pipe can be cut and joined on-site, minimizing production stoppage.

Within the confined spaces of the plant, slip joining a CPVC pipe is significantly easier than threading a steel part. Even when moving pipe from one tank to another, it's simple to cut CPVC pipe, move it to the designated tank and rejoin it.

The Solution Delta, and You, Can Trust

Corzan CPVC provides a solution that is reliable, durable, easy to install, modify, and repair, and still meets the stringent safety assurance standards set by several industries, including:

- Water and wastewater treatment

- Chemical processing

- Chlor-alkali

- Mineral processing

- Power generation

- Semiconductors and electricity

To learn more about how Corzan CPVC can benefit your plant, or if you are interested in a free consultation on chemical resistance, process suitability or any technical questions, contact us.