Determine If Corzan CPVC Will Resist the Chemicals in Your Application

Not even the Environmental Protection Agency (EPA) knows how many different chemicals are in use today – although the agency has more than 85,000 chemicals listed as substances that fall under the Toxic Substances Control Act (TSCA).

Only a fraction of these substances, fortunately, are used in industrial processes that involve piping systems. Piping materials, however, must be correctly specified for the chemicals utilized during industrial processes – even if contact with a substance is unintentional – to ensure reliable performance without chemical resistance-related issues.

Engineers often specify thermoplastics such as Corzan CPVC® (chlorinated polyvinyl chloride) for industrial environments because they are inert to most acids, bases and salts, and aliphatic hydrocarbons.

Corzan CPVC’s Chemical Resistance

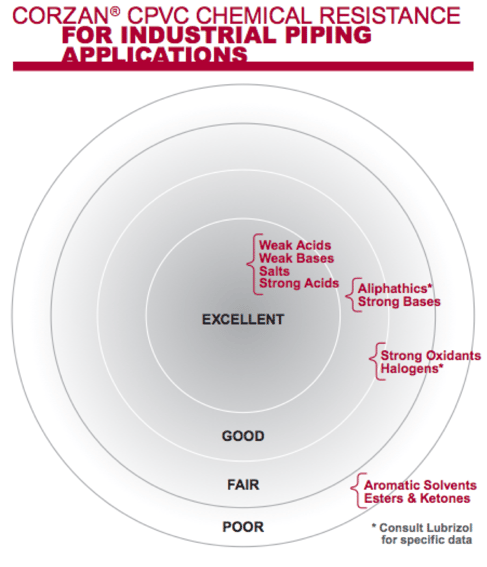

Corzan CPVC offers excellent resistance to a broad range of corrosive chemicals – the same acids, caustics, salts and other chemicals that can degrade and reduce the service life of many metal piping systems. Replacing traditional metal piping materials with Corzan CPVC, therefore, presents opportunities to extend equipment service life, reduce maintenance and minimize process life-cycle costs.

The Corzan CPVC Chemical Resistance Chart confirms Corzan CPVC’s resistance to over 400 different chemicals. The information presented is based on test data and field experience of CPVC manufactured by Lubrizol and does not reflect the properties characteristic of other CPVC materials.

Corzan CPVC piping and fitting materials are not pH limited and can accommodate wide pH swings in the fluids they transport, making the piping system applicable for use with chemicals utilized in a variety of industrial operations, including chemical processing, chlor-alkali, food and beverage, metal finishing (chrome plating), mineral processing, power generation, pulp and paper, semiconductor and wastewater treatment.

Chemical Resistance-Related Issues

Corzan CPVC piping that is incorrectly specified for a particular chemical application can experience problems such as softening, degradation and cracking, which can result in failure. These issues may develop even if the piping material unintentionally comes into contact with an incompatible chemical.

Softening is characterized by a swollen and/or distorted appearance that will eventually cause a failure by ballooning and ductile rupture or by system distortion. Absorption of solvents or plasticizers – either from the process fluid or from the external environment -- is one of the primary causes of softening.

CPVC piping is generally not recommended for use with most solvents, whether soluble or insoluble, although some water-soluble solvents may be suitable at low concentrations. The potential exists for water-insoluble solids to be absorbed out of process fluid even if present in low concentrations. What makes plastics so special is their ability to be effective in non-ideal situations. While CPVC would not typically be utilized in concentrated solvent pressure systems, utilization in low concentration drainage or waste situations may prove very effective. It is critical that the full application conditions are considered in totality to properly assess suitability.

Piping may also absorb solvents or plasticizer from the external environment. Gasketing materials, caulks, rubber padding or lining materials may contain plasticizers that can migrate into the rigid vinyl over time, resulting in softening and eventual rupture under pressure.

Design engineers must be aware of these limitations and specify the proper ancillary materials to prevent these types of compatibility-related issues.

Degradation results when the vinyl resin or other compounding ingredients in the CPVC piping material are altered or destroyed. Signs of degradation may include blackening and blistering of the material surface.

Degradation can be caused by prolonged exposure to conditions that exceed the recommended temperature, pressure and chemical concentration (TPC). Or, it may result from exposure to chemicals that react with and destroy the base polymer of the compounding additives, such as certain amines and ammonia.

When used in applications that exceed its TPC recommendations, Corzan CPVC may experience blackening and blistering from hot, concentrated sulfuric acid or whitening and surface etching from hot concentrated nitric acid.

Environmental Stress Cracking, often referred to as ESC, occurs when an organic chemical (perhaps a weak solvent or non-solvent) creates an extremely localized weakening at the piping material’s surface, resulting in a crack. The crack generally includes glossy fracture surfaces that occur in regions of high mechanical stress.

ESC results when both the chemical and a significant level of mechanical stress are present. Potential ESC agents that impact CPVC piping include natural or synthetic ester oils, nonionic surfactants, and alcohols.

Taking a Holistic Approach

Once engineers determine that Corzan CPVC is chemically resistant to the application media, they must consider the impact of temperature and pressure combined with the presence of aggressive chemicals. The full pressure rating may not apply to the entire range of concentrations and temperatures designated as recommended. Corzan CPVC provides superior resistance to corrosive chemicals at high temperatures and pressures.

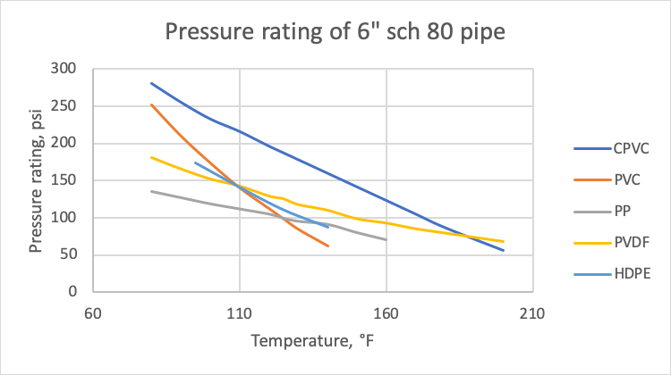

Corzan CPVC may be used for pressurized service up to 200°F and offers a higher pressure rating over most of its useful temperature range compared to other thermoplastic materials, as illustrated in the graphic that follows.

Other thermoplastic materials such as PVC, polypropylene or HDPE have a maximum pressurized service temperature as low as 140°F or 160°F. Some grades of HDPE may be pressure rated as high as 180°F, but these materials’ maximum pressure at elevated temperatures is low compared to Corzan CPVC.

Installing piping systems with higher maximum temperature and pressure ratings provides facilities greater flexibility when handling process fluctuations or the changes in operating conditions that eventually occur in many industrial applications.

Specifying the Correct Piping Materials

Piping materials must be correctly specified for the chemicals utilized during industrial processes – even if contact with a substance is unintentional. Corzan CPVC offers excellent resistance to a broad range of corrosive chemicals and has proven successful in a range of industrial applications worldwide for nearly 60 years.

Visit our website, contact a Corzan engineering expert or one of our partner manufacturers for more information about Corzan CPVC chemical resistance and other product advantages that ensure a safe, reliable and cost-effective piping system.

Information for this blog was taken, in part, from the following Lubrizol resources:

https://www.corzan.com/en-us/chemical-resistance-and-chemical-applications

https://www.corzan.com/en-us/corzan-cpvc-chemical-resistance-chart