How to Optimize an Industrial Piping System for Pressure Loss

Piping systems are designed to satisfy a specific flow rate and fluid pressure at critical junctions within an industrial application. If the pressure is too great or insufficient, operational issues can emerge leading to avoidable expenses.

As part of this, industrial engineers must account for pressure loss (or pressure drop). Pressure loss is the result of frictional forces exerted on a fluid within a piping system, resisting its flow. As pressure loss increases, the energy required by system pumps to compensate also increases, leading to greater operating costs.

Complicating things further, some of the factors affecting pressure loss can vary over the life of a piping system. In some cases, design considerations must be made up front to account for influences that won’t surface for five to ten years.

So how can an industrial process truly optimize its piping system for pressure loss both now and over the life the system? The answer starts with understanding what influences pressure loss.

What Causes Pressure Loss in a Pipe?

Depending on the system, there are a number of competing forces working to either decrease or increase the fluid pressure from one end to the other. To optimize a system, the following factors should be taken into account.

Constant Factors: These factors will remain constant throughout the life of the system.

- Gravity: Increases and decreases in elevation will cause system pressure losses and gains, respectively. It is important to understand the net effect of elevations changes on the system pressure.

- Piping Path and Valves: Throughout a piping system, fittings, bends, valves, expansion joints, and any changes in direction will result in friction causing pressure loss.

- Pipe Size: Piping diameter has an inverse effect on pressure. Water forced through an 8-in. Schedule 80 pipe will exit the pipe at a pressure much less than the same amount of water forced through a 4-in. Schedule 80 pipe over the same time interval.

Variable Factors: These factors may fluctuate during the life a piping system.

- Material Friction Force: Every piping material used throughout a piping system has a friction coefficient, or a measure of roughness, that slows a fluid. The smoother the material surface, the higher the Hazen Williams friction coefficient and the easier the fluid can pass over it. Depending on the material, this coefficient can change over time. For example, Corzan® CPVC has a Hazen Williams C-Factor of 150 throughout the life of the pipe, compared to a new cast iron pipe, which has a C-Factor of 120 upon install, but can drop to 60-80 over time with wear or pitting.

- Corrosion: Occurs when charged ions in a fluid eat away at metal materials causing pitting along the piping surface or at joints. This pitting slows fluid flow.

- Scaling: Occurs when ions attracted to metal surfaces build up along the system, typically around seams or flanges. As scaling occurs it constricts the fluid flow and increases pressure within the pipe.

How to Calculate Pressure Loss in a Piping System

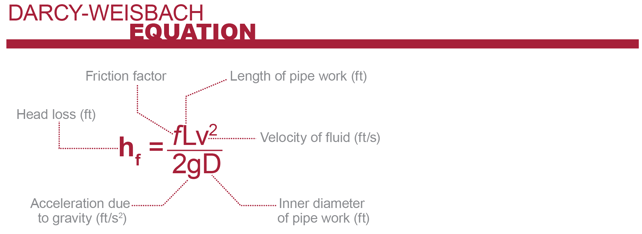

The Hazen-Williams Equation is often used to calculate pressure loss within a piping system. However, the Darcy-Weisbach Equation is often preferred for industrial piping systems.

While the Hazen-Williams equation can work for many systems, it makes assumptions that may not apply to all industrial applications, namely the fluid being water and the fluid temperature being 73°F (22.8°C).

The Darcy-Weisbach Equation allows for flexibility when it comes to the fluid and temperature.

How to Optimize an Industrial Piping System

The most effective way to optimize an industrial system for fluid pressure is by adjusting pipe diameter. It is also one of the easiest to control.

However, to effectively specify pipe size it helps to control those factors that can change over time. For example, in a metal piping system, the piping diameter may need to be wider than is initially necessary as material friction and some corrosion and/or scaling needs to be accounted for.

Conversely, an industrial piping system that specifies Corzan® CPVC material can eliminate these influences allowing for a narrower pipe to be specified:

- CPVC has one of the best Hazen-Williams C-Factors of any piping material, and it maintains that factor throughout the life of the piping system.

- CPVC is resistant to corrosion as it is inert to the acids, bases and salts that eat away at metal piping.

- CPVC does not allow for scaling, as the ions that bind to metal piping are not attracted to thermoplastics.

Interested in the capabilities of a Corzan industrial piping system to reduce the friction posed on your fluid? Our team of product and engineering specialists are available for a free consultation if you have any questions or upcoming projects you’d like to discuss.