The Role of Solvent Cement in Welding CPVC Pipe & Fittings

“Glue” is a term commonly inappropriately applied to the solvent cement process for thermoplastics. It is true that some types of thermoplastics utilize glues, but not all. Don’t let misconceptions about joining methods be the downfall of your project. CPVC materials manufactured to ASTM standards, such as ASTM 441 and ASTM F439, are designed to be chemically welded through a process known as solvent cement welding. It is not a glue.

Some incorrectly believe that solvent cement joints are the weakness in the system – more than 60 years of experience with CPVC tells us this is not the case. Corzan® CPVC is the most specified industrial grade CPVC technology in the world. Proven performance is at the center of the technology’s reputation. In order to create a strong joint, the pipe and fittings must have a tolerance relationship that allows for a true bonded connection. ASTM F439 requires the following: “The minimum burst strength of the fittings shall be not less than that calculated for the size and wall thickness of the pipe with which it is to be used.” Laboratory testing and our decades of experience have shown us that a properly done solvent cement joint will not fail prior to the actual pipe failing, as this video shows.

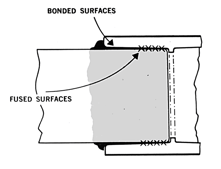

This is because the role of the solvent cement is to work in conjunction with ASTM F656 primer to create the chemical bond in the joint. See the diagram of a joint below. The tapered fittings provide a mechanical force when the pipe is fully inserted.

How do I create a proper solvent cement joint?

The simplest way to ensure a proper solvent cement joint is training. The solvent cement process involves understanding the purpose of the primer, the solvent cement, the pipe-to-fitting relationship, and how environment can affect the outcome. The American Welding Society has issued AWS b2.4 that covers welding of thermoplastics. AWS combined with ASME B31.3 bonder qualified installers is a recipe for success. Download the Complete Solvent Cement Guide for more details.

How is solvent cement welding if there is no heat?

Traditional welding of metallics involves hotwork that creates an ignition source. This can be very dangerous and harmful if the right PPE is not worn. In the solvent cementing process, the primer is similar to the “heat” and the solvent cement is the welding rod that completes the weld. In a two-step process, the primer functions in much the same way as applying heat would; it softens the CPVC, the tapered fittings provide the site of the weld, and the pipe when inserted causes the polymer chains once again intertwine. The resulting joint has the strength of the original material or greater. Often erroneously referred to as “glue,” solvent cement is nothing like glue, which holds material together simply by functioning as an adhesive.

What are the Recommended Solvent Cement Products for Corzan CPVC?

The companies, E-Z Weld, Mainline, Oatey and Weld-On, are your go-to suppliers for CPVC solvent cement. Check out our Solvent Cement Guide to understand your options.

Corzan piping systems have successfully provided products for industrial applications worldwide for more than 60 years. Contact a Corzan engineering expert or one of our partner manufacturers for engineering guidelines to specify a safe and reliable piping system or to schedule a free process suitability review and technical assessment.