The Basics of CPVC Hot Air Welding

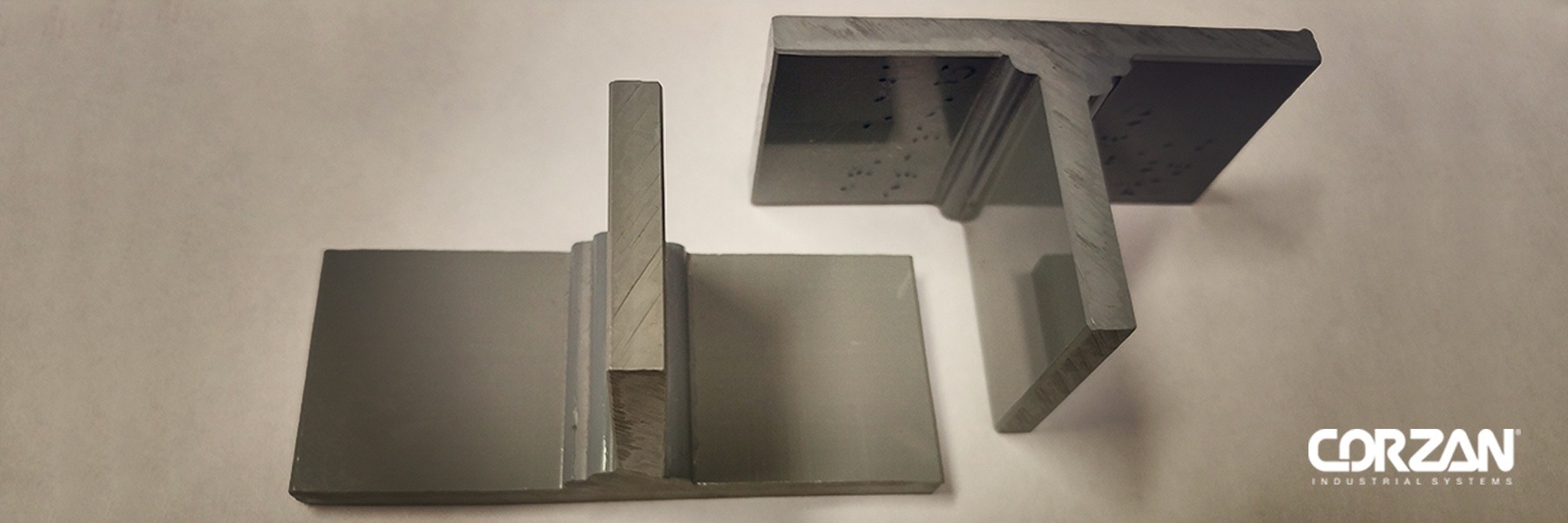

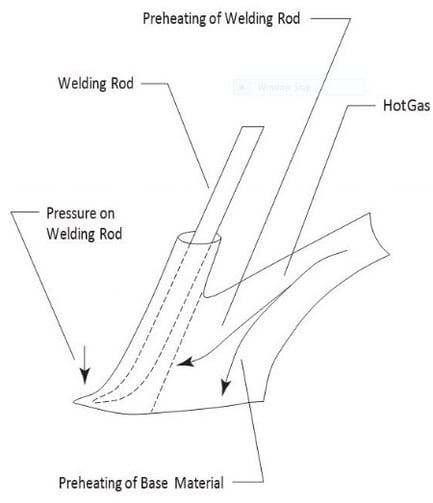

Hot air welding is a joining method that uses high heat to make chlorinated polyvinyl chloride (CPVC) material reach its melt state. Pushed together for a certain amount of time at a specific pressure, this method allows the surface molecules of the two pieces to interlock, fusing them together.

Hot air welding is an essential technique for CPVC sheet fabrication and can also be used to join pipes and other geometries when other joining methods are not an option.

Hot Air Welding vs. Solvent Cement

Though solvent cement is the preferred joining method for CPVC systems, it is only effective when there is an interference fit—when the two pieces can naturally press together.

The most common instance of this is with pipes and fittings. Because the fitting is slightly tapered, when the pipe goes in, it experiences strong contact with the fitting wall, holding the two pieces together.

Under these conditions, solvent cement is able to soften the two pieces and utilize the inherent pressure of the fit to create a strong, uniform joint.

In joining situations where consistent pressure and contact between the two faces is not possible, hot air welding is recommended. Though a very versatile joining method, it is most frequently used to join CPVC sheet for:

- Sheet fabrication

- Tank linings

- Scrubbers

- Exhaust systems (e.g. fan housings)

Key Factors of Hot Air Weld Performance

While solvent cement is a fairly straightforward process that can be taught over a short period, welding requires more expertise and detail to deliver high quality joints. Dependable hot air welded joints require that you:

1. Use Quality Equipment

High quality hot air welding equipment is needed to deliver consistent results, as these instruments can provide:

- Clean, dry air that is free of oil and moisture

- Consistent airflow supplied at a low pressure and high volume.

- Accurate temperature controlling equipment to maintain the specified temperature of the thermoplastic.

2. Follow the Correct Steps Prior to the Structural Welding Process

Before starting a weld, fabricators must carefully:

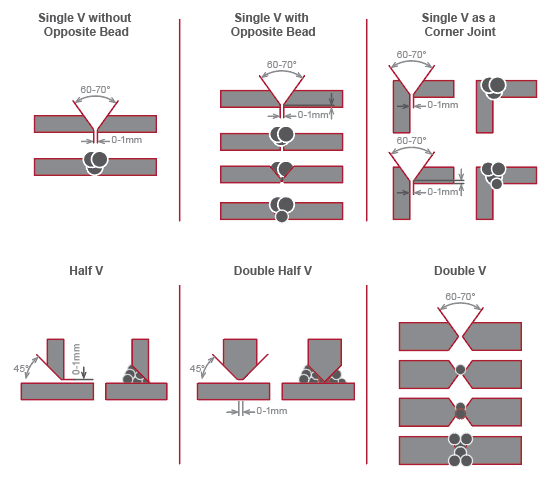

Prepare the Material. Bevel the ends of the adjoining pieces, following the recommended joint configuration based on the type of joint and filler. After beveling, the assembly must be cleared of residue.

Select a Welding Rod. This selection depends on the specific material and manufacturer. For example, Corzan® CPVC hot air welding requires the use of Corzan CPVC welding rods. Stronger joints are created through the use of smaller diameter rods with multiple beads, as they lessen the potential for gaps. After selection, ensure the welding tip diameter matches that of the welding rod.

Tack Weld the Seam. Depending on the seam's curvature length, you may consider tack welding to start. Tack welds are intermittent spot welds along the seam that hold the material in place. This process helps prevent any slippage that may occur during the structural welding process.

3. Choose Skilled Welders or Fabricators with Experience

In many cases, a hot air weld is only as good as its fabricator. Just as steel welding requires training and skill, experienced thermoplastic welders are required to consistently achieve reliable hot air welds. Otherwise, CPVC’s inherent properties and expected lifecycle value could fail to be fully recognized.

4. Consider an Annealing Process

During the manufacturing, handling and welding process, thermoplastic materials may be introduced to new stresses that may compromise the system slowly over time. To account for this, fabricated parts may be heated in an annealing oven slowly over several hours or more, and then cooled gradually in a similar manner.

While not always necessary or performed, annealing reduces any internal stress that may have built up during the fabrication process.

Learn More About Hot Air Welding

To find a qualified fabricator or to discuss your system's requirements, our team of product and engineering specialists are available to schedule a free consultation. They're happy to pair you with welders in your area and advise you on the most effective approach to system fabrication.

Refer to our guide on CPVC hot air welding to learn more details about this important joining technique.