The Pipe and Fitting Material More Wastewater Engineers are Turning To

Water and wastewater infrastructure in the U.S. continues to deteriorate as its repair stays on the back burner due to economic uncertainty and lack of funds. To address costly repair issues, engineers and end users must think beyond what was good enough in the past and adopt innovative technologies that offer more economical installation, higher durability and reduced total life-cycle costs.

Water Treatment Piping Options

Carbon steel and stainless steel have traditionally been the go-to piping materials for water and wastewater applications because of their perceived strength. However, after years of field use, issues with corrosion, pitting, scaling and gradual pressure loss lead to excessive repair costs for underfunded facilities. The high cost for stainless steel can also put replacement of aging systems out of reach.

As a result, chlorinated polyvinyl chloride (CPVC) is emerging as the material of choice for pipe and fittings in water and waste applications with an increasing number of engineers adding it to their in-house specs. They are finding that CPVC is not only highly resistant to microbes and chemicals used throughout the process, but it also boasts lower installation costs plus durability and pressure ratings that do not diminish over time—providing a lower total cost of ownership.

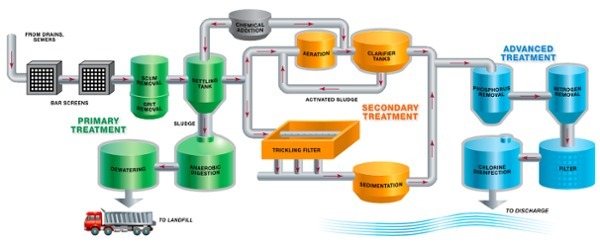

With its corrosion resistance, CPVC has proven to be highly reliable and cost effective in primary, secondary and advanced treatment of wastewater, as well as in ancillary equipment, scrubbers, desalination processes, dual-containment applications, and water treatment and distribution. Because of its versatility, CPVC offers efficiencies in inventory control because only one material needs to be stocked for a wide array of uses.

CPVC in Primary Treatment

CPVC is ideal for use throughout the primary treatment process as effluent utility piping and to connect treatment stations, including:

- Bar screens

- Scum / grit removal

- Filtering equipment

- Anaerobic digesters

- Chemical addition tanks

During primary treatment, piping is exposed to the harshness of several substances, such as:

- Microorganisms

- Ferrous chloride

- Alum

- Alkaline lime slurry

- Other clarifying and thickening chemicals

With metallic piping, these corrosives will gradually impact the integrity of the system. For example, 316 stainless steel has a Hazen Williams C-factor of 120 when it is new. The Hazen Williams C-factor represents the interior smoothness of the pipe—the higher the C-factor, the smoother the pipe. Over time, pitting and scaling will cause the pipe’s interior to become less smooth, reducing the C-factor and increasing the pressure loss as liquid flows through the system. When this happens, facilities must often install larger pumps—and use more energy—to achieve the needed output of treated water.

On the other hand, CPVC starts with a C-factor of 150 and maintains its interior surface smoothness throughout its life by resisting the effects of corrosives found in the wastewater treatment process. This leads to greater efficiencies and reduced costs to facilities because smaller pipes, smaller pumps and less energy can be used to move fluids at the same rate. This is true in primary treatment and at every subsequent stage in the treatment process.

CPVC in Secondary Treatment

In the secondary wastewater treatment processes, piping is exposed to high concentrations of microorganisms when excessive biological growth washes out and collects in a clarifier. Byproducts of these microbes, including acids such as hydrogen sulfide, along with disinfectants and dechlorination chemicals, contribute to the corrosion of metallic piping systems.

CPVC’s corrosion resistance makes it ideal for everything from carrying concentrated acids and caustics used in pH control, to carrying sludge and chemically treated water through aeration and filter equipment, to sodium hypochlorite feed and generation piping.

CPVC in Advanced Treatment

As in the preceding processes, CPVC piping meets the demands of advanced treatment by performing reliably even in cooling tower applications and when handling nominal concentrations of methanol used in biological denitrification.

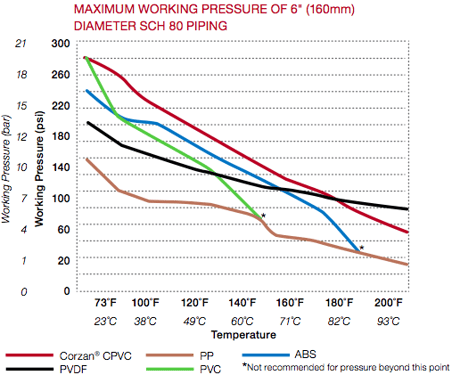

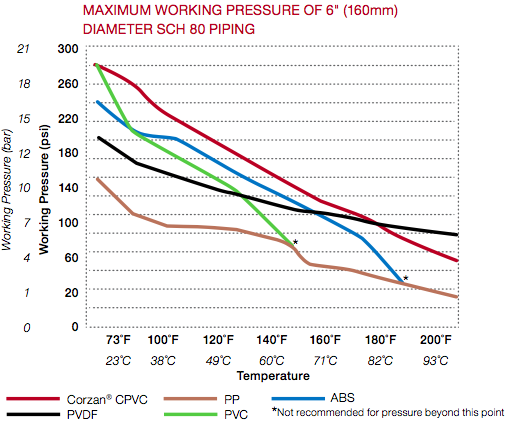

CPVC pipe is pressure rated at operating temperatures up to 200°F. The high temperature and corrosion-resistant properties of CPVC make it an ideal material in advanced treatment when carrying treated water and chemicals through phosphorus removal, nitrogen removal, filtration and chlorine disinfection.

Outdoor Installations

Since a large amount of piping in a treatment facility can be installed outdoors, the effect of direct sunlight on the material must be taken into account.

Direct sunlight causes degradation to many non-metallic piping systems. Gray CPVC, however, contains UV-protective levels of both carbon black and titanium dioxide (TiO2). Both carbon black and TiO2 are widely recognized as excellent ultraviolet blocking agents and help to protect the polymer backbone from the effects of ultraviolet radiation.

The combination of ambient temperatures and radiant solar heat can raise the surface temperature of piping materials to temperatures that exceed the limit of the material.

Refer to the following graph that shows the estimated surface temperature of piping systems at various ambient temperatures when exposed to direct sunlight.

Other CPVC Uses

With today’s long list of odor control mandates, CPVC is a proven material used in both traditional wastewater applications, mentioned above, and in scrubbers and ancillary equipment. Whether a plant is using sodium hydroxide and sodium hypochlorite in its wet-air scrubbers at temperatures as high as 200°F, or using metal chelating agents in a liquid redox process, advanced CPVC offers the chemical resistance and superior high-temperature performance that wastewater odor control processes require.

Further, in desalination applications, CPVC outperforms metallic systems because it can handle the chemical feeds for reverse osmosis processes. Because it is not susceptible to corrosion by high chloride levels, there is no need to pickle or passivate the piping system and no need for expensive cathodic protection against corrosion—reducing the cost and complexity of installation.

Not All CPVC is Equivalent

With the many benefits of CPVC piping systems, it’s no wonder budget-strapped water treatment facilities are turning to this material for improved reliability, lower installation costs and lower life-cycle costs. But, buyer-beware, not all CPVC is the same.

To gain maximum benefits, look for CPVC pipe and fittings that exhibit:

- The highest drop impact strength—there are available systems that are up to three times stronger than competitive systems

- The highest heat distortion temperature—especially in outdoor installations where surface temperatures might go above the system’s maximum rated temperature

- Excellent creep resistance and ability to withstand long-term pressure at high temperatures

- NSF International approvals for potable water

In applications with heightened pressure requirements, it may be necessary to look for piping materials that exceed ASTM F441 material classification requirements for higher pressure capabilities, such as Corzan CPVC technology.

Even when budgets are a concern, the right CPVC pipe and fittings supplier can help you design an entire system or retrofit solution that will stand up to the high demands of the wastewater treatment process—and help you reduce your maintenance costs long term.

Need Technical, Specification or Engineering Support?

From spec writing to installation, our team of industrial and engineering experts are here to provide the advice, information and training needed to select and integrate the best piping solution for your application. Request a free consultation.