How CPVC Piping Unlocks Pulp and Paper Mill Cost Savings

In virtually every industry today, manufacturers look for ways to make operations more cost effective. In the pulp and paper industry, this includes seeking new piping materials and methods that reduce costs while maintaining piping performance and satisfying processing requirements.

The key objective is to find new or improved corrosion resistant materials that reduce overall costs and maintenance, while providing long-term service.

To reduce costs and maintain lifecycle performance, paper and pulp mills are increasingly specifying piping systems made from Corzan® CPVC (chlorinated polyvinyl chloride). Read further to learn how this industrial thermoplastic delivers a high performing balance of properties that provide value to paper and pulp applications.

Corzan CPVC: Delivering Reliability

The most important characteristic of Corzan CPVC is its corrosion resistance – a known necessity in an industry where harsh, highly corrosive chemicals are routinely used.

However, it is CPVC’s balance of qualities that goes beyond corrosion resistance, including hydraulic capability, abrasion resistance, and lower thermal conductivity, that produce both long service life and cost savings. Plus, CPVC piping is lightweight and easy to install.

These savings can be recognized from beginning to end, enabling lower:

- Piping costs

- Installation costs

- Retrofit costs

- Overall maintenance costs

This combination of features makes CPVC industrial piping a preferred material for many pipe service applications within the pulp and paper process.

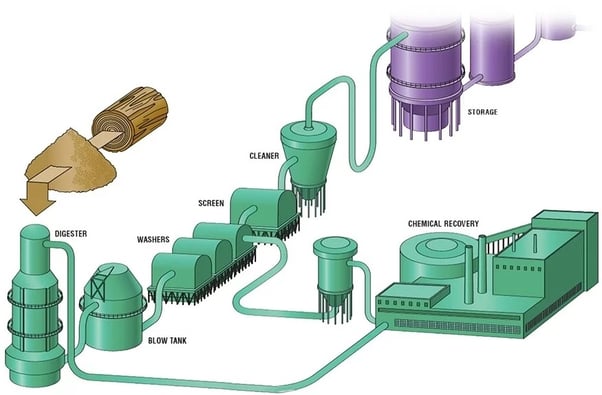

Pulp / Chemical Recovery Process

An integral part of the chemical pulping process is the recovery of chemical cooking liquors. Equally important is the mill’s ability to re-use these liquors and other process byproducts.

Piping in this operation must have the ability to withstand a range of acids and bases at elevated temperatures. Corzan industrial pipe has excellent chemical resistance to caustic soda, calcium carbonate and lime, which are used in the chemical recovery of kraft cooking liquors.

In a possibly more demanding application, CPVC piping is recommended for use in black liquor spent acid lines. Tall oil byproduct production calls for similar spent acid handling and transfer of dilute sulfuric acid solutions, which are currently handled by Corzan industrial piping.

Chemical recovery systems for sulfite pulp also utilize sodium base systems, which demonstrate good chemical compatibility with CPVC. Additionally, the pipe’s abrasion-resistant properties can provide selected use for effluent handling and slurry lines.

View the Corzan Chemical Resistance Table for CPVC's compatibility with 400+ chemicals.

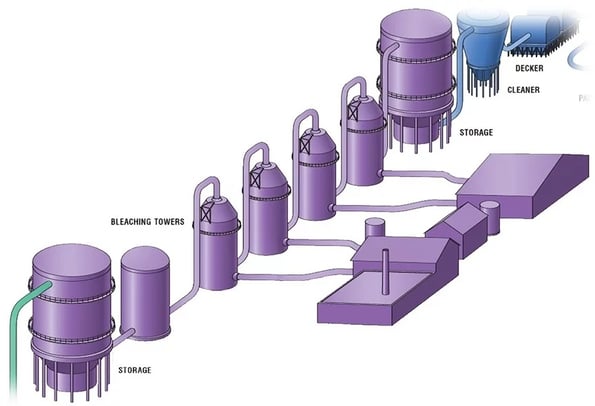

Bleach Plant Operations

Bleach plant piping systems are exposed to the most corrosive environment within the pulp and paper process, with chemicals such as chlorine dioxide and hydrogen peroxide used in multiple stages in the bleaching process.

These solutions can affect the service life of carbon steel and stainless steel piping materials. Corzan piping, however, has demonstrated excellent service in bleach plant process lines and exhibited continued performance when exposed to several corrosive acidic and caustic solutions found in bleach preparation and process operations.

Corzan piping has been used to handle sodium hydroxide, sodium chlorate, sodium chloride, and hydrochloric and sulfuric acids. CPVC can service chlorine dioxide, sulfuric acid, and hydrogen peroxide piping requirements where metallic materials exhibit internal and external corrosion problems.

Corzan CPVC was specified in a corrosive bleach plant plant over stainless steel, carbon steel and fiberglass because of its cost effectiveness and performance. Click here to learn more.

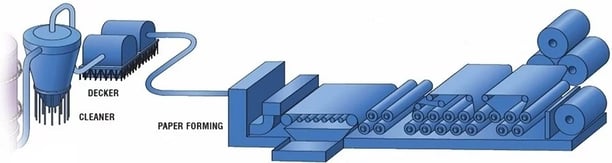

Stock Preparation / Paper Making Operations

Before papermaking or sheet forming, several stock additives are added to the pulp to improve the properties of the paper or to facilitate processing.

These additions include a variety of:

- Pigments

- Sizes

- Coloring materials

- Dry and wet-strength resins and fillers

They are handled in liquid form as stock solutions or through slurry lines. Chemical and abrasion resistance are important considerations in the selection of piping materials in the operation.

CPVC is chemically inert to most stock additives and papermaking chemicals, which includes:

- Rosin

- Starches

- Titanium dioxide

- Various waxes

Also, extensive and reliable handling of fresh and white water during the papermaking process makes Corzan piping systems a favorable alternative to metal pipe.

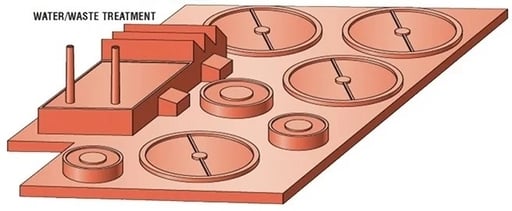

Water Handling and Distribution

The pulp and paper industry is one of the largest users of water. As a result, the distribution and recovery of water is an integral part of operation in paper production.

Pipe corrosion problems caused by aggressive water will affect the required efficient handling of these fluids. Extensive corrosion results in inefficient flow rates, premature failure and expensive repairs.

Corrosion resistant CPVC industrial piping systems have been used in water distribution for nearly 50 years and are recommended for most plant water supply and distribution lines.

Other Corzan CPVC applications include:

- Waste water piping and drains

- White water service

- Water drainage

- Effluent piping

- Service lines in pollution control

- Waste water treatment operations

Learn more about Corzan CPVC for water and wastewater applications: 8 Reasons CPVC is Ideal for Industrial Water Process Piping Applications.

Other Mill Applications

The outstanding balance of properties offered by materials made from the Corzan CPVC compound make it suitable for other uses in the pulp and paper mill.

CPVC packing media are utilized in bleach plant and lime kiln wet scrubber systems.

Dual laminate piping and vessel construction utilizing Corzan CPVC and / or sheet as the exposed corrosion resistant barrier in a process system offers multiple benefits. It creates a product with excellent chemical and abrasion resistance while simultaneously offering superior strength with the addition of fiberglass on the exterior of the pipe or vessel.

Other CPVC specialty molded and fabricated fluid handling products in current use in chemical process industries include valves, pumps, and basket strainers.

Learn More About CPVC

Delve deeper into the benefits of alternative piping materials, in terms of cost and performance with this CPVC guide: