THREADING AND FLANGING CPVC PIPING SYSTEMS

Threading and Flanging CPVC Piping Systems

Issues that develop in piping systems often involve connections, which is why it is important to select and properly install all transitions/connections. Depending on the application and the pipe size, CPVC pipe transitions may be threaded or flanged, although flanging is generally the preferred method especially when disassembly is required.

When determining the best transition method for a piping system, always consider the severity of the service – whether the piping system will carry chemicals, water or wastewater, acids or caustics -- and choose the best method for the application to avoid leakage. Every Corzan® CPVC manufacturing partner provides engineering guidelines for making safe and reliable transitions.

Threading Versus Flanging

Threading of the pipe has long been an acceptable transition method. However, it is most common in low pressure piping systems transporting low risk fluids. But even though threading CPVC may be perceived as a less expensive alternative for creating connections, plastic threads are similar to stainless steel in that they can be perceived as soft and over tightening or over torquing is possible if the pipe fitters are not properly trained on working with non-metallics. It is common to consider type of fluid, maximum surge pressures, and thermocycling conditions when selecting the best transition method for the system.

Lubrizol typically recommends that Corzan CPVC Schedule 80 pipe may be threaded for sizes up to and including a 4-inch diameter operating at 130°F (54.4°C) or less. Threads must be in accordance with ANSI B1.20.1 Taper Pipe Thread.

It is important to note, however, that threaded pipe is derated to 50 percent of the pressure rating of the Schedule 80 pipe at the operating temperature. Threading should not be used with Schedule 40 pipe, Schedule 80 pipe larger than 4 inches or piping systems that will operate at temperatures exceeding 130°F. Flanging or mechanical coupling should be used in these circumstances.

Flanges Require Gaskets

Flanges used in piping incorporate an elastomeric gasket between the mating faces to provide a seal. The pipe gasket selected must be full-faced and have a hardness of 55-80 durometer A. Gaskets are generally 1/8-inch thick and the material selected must be resistant to the chemical environment to which it will be exposed and chemically compatible with CPVC.

As with piping materials, gasket selection and installation strongly impact the piping system’s overall performance and life expectancy. Gaskets are available in a variety of materials since no single material can withstand the demands of every application.

Choosing a material that is inert to the effects of the fluid flowing through the piping systems ensures a strong joint that will maintain pressure and performance throughout the piping system’s life. Acids, bases and salts interact with materials at the molecular level in their own unique ways. The Corzan CPVC Chemical Resistance Chart shows the compatibility of CPVC when tested with more than 400 different chemicals.

Heat will impact the gasket material. Fluids in industrial applications often have a specific temperature and the higher the temperature the more unstable a compound’s molecules become, Different materials stand up better to elevated temperatures than others.

The gasket material’s compatibility with the piping material is also a consideration. Some gasket materials have the potential to leach into CPVC to create small fractures that weaken the material and the pipe joint.

How to Install Gaskets

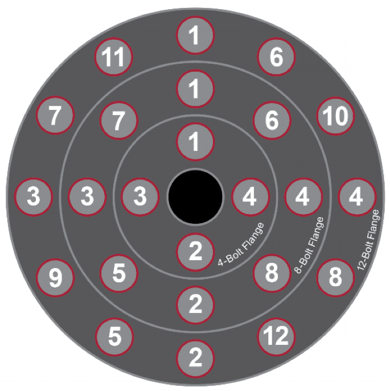

During installation, flanges must be properly aligned, and bolts inserted through matching holes. Use a flat washer beneath each nut and bolt head and partially tighten each bolt in the alternating sequence indicated in the pattern below.

Flange Bolt Tightening Patterns

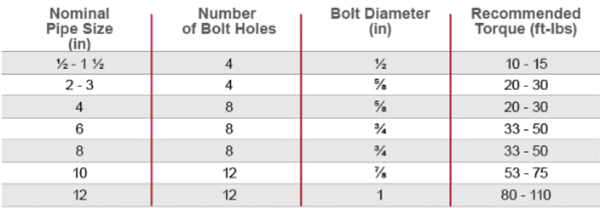

Proper torque is essential during gasket installation to ensure the flange is not damaged. The challenge with gaskets is that too little or uneven pressure can create openings that will result in leaks. Over-compression, on the other hand, can structurally jeopardize the gasket materials and place excessive stress on the joint, limiting its performance.

Corzan engineers have determined the appropriate flange bolt torque for various pipe sizes. However, Corzan manufacturing partners provide guidance based on their specific design and should be consulted as well.

Recommended Bolt Torque

Piping system transitions are always the decision of the system owner based on what is best for the specific application. Properly installed flanges are often a safe and reliable option as they can absorb the stresses associated with the expansion and contraction common to many piping systems while providing years of service.

It is essential, however, to always follow the recommendations provided by system manufacturers to ensure proper installation of flanges or threads. For more information, contact a Lubrizol partner manufacturer or a Corzan CPVC System Consultant for a free technical assessment. Lubrizol’s product and technical support is backed by 60 years of CPVC experience.

Information for this blog was taken, in part, from the following resources:

https://www.corzan.com/en-us/piping-systems/installation/flanging

https://www.corzan.com/blog/how-to-choose-the-correct-gaskets-for-your-industrial-piping-system