What To Know About CPVC Classifications and Cell Classes

ASTM F441 is the Standard Specification for CPVC Plastic Pipe, Schedules 40 and 80. Per the standard’s requirements and test methods, CPVC is assessed for “materials, workmanship, dimensions, sustained pressure, burst pressure, flattening and extrusion quality.”

Another set of CPVC standards is defined by ASTM D1784. This specification assesses CPVC according to “base resin, impact resistance under notch, tensile strength, modulus of elasticity in tension, deflection temperature under load and flammability.”

By specifying CPVC that meets ASTM F441 and ASTM D1784, users should have confidence that their industrial piping systems will perform as expected. Yet, not all approved CPVC is created equal. Within each standard are distinctions that set certain CPVC compound producers and manufacturers apart.

Hydrostatic Design Stress Differences

In the designation code 4120, the “41” represents a minimum Cell Classification of 23447 as defined ASTM D1784. The “20” represents a Hydrostatic Design Stress (HDS) of 2000 psi (14 MPa) for water at 73ºF (23ºC).

HDB is the estimated long-term strength of a pipe. The test and data collection method used is ASTM D2837, or the Standard Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials.

In the test, pipe is pressurized and assessed for 16,000 hours (nearly a year and ten months) at a temperature of 73°F (23°C) and 180°F (82°C). The hoop stress, or circumferential stress, collected over that time is then extrapolated over 100,000 hours. The estimated strength of the pipe after those 100,000 hours (nearly 11 and a half years) is known as the hydrostatic design basis (HDB).

From there, the HDB is used to calculate the hydrostatic design stress (HDS), which is 50% of the HDB. This creates an inherent safety factor for the pressure rating of plastic piping.

CPVC 4120-05 vs. CPVC 4120-06

The results of that test are used to define the difference between CPVC 1420-05 and 1420-06. CPVC 1420-06 has a better hydrostatic design status at higher temperatures.

- CPVC 4120-05 has a minimum HDS of 500 psi for water at 180°F (82°C)

- CPVC 4120-06 has a minimum HDS of 625 psi for water at 180°F (82°C)

For plants, the most significant advantage of CPVC 4120-06 is that it has a superior pressure rating and a lower derating factor as the temperature increases.

Specifically, CPVC 1420-06 will have a 25% better pressure rating at 180°F (82°C) than CPVC 1420-05.

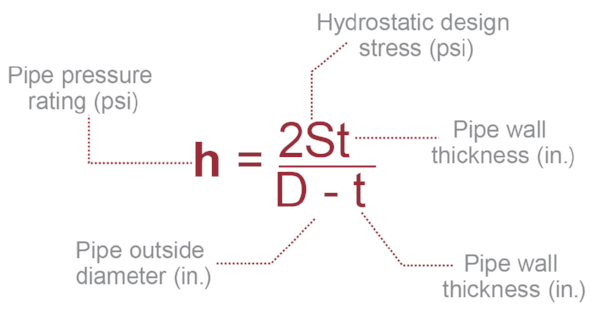

How Pipe Pressure Rating Is Calculated Using HDS

Once the hydrostatic design stress (HDS) has been determined through the test described above, calculate a pipe’s pressure rating using the following formula:

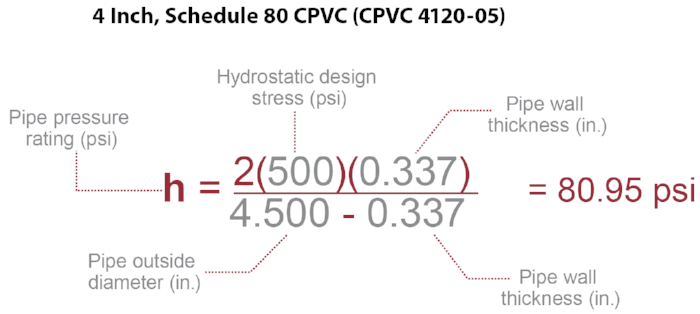

To use that formula to show the difference between the two classifications for CPVC, consider a 4-inch, schedule 80 pipe that has a wall thickness of 0.337 inches (t) and outside diameter of 4.500 inches (D). The only variable that changes is the HDS.

-1.png?width=700&name=pipe-pressure-rating-equation_Ex%20(1)-1.png)

As the example above shows for 4-inch, schedule 80 piping, the CPVC that meets 4120-06 has a pressure rating of 101.19 psi, or 25% higher than the pressure rating for a CPVC meeting 4120-05, 80.95 psi.

CPVC that meets 4120-06 better meets the demands for industrial systems facing higher temperatures and pressures. Even for systems not expected to reach those levels, 4120-06 piping still increases the system’s safety factor, reassuring plant workers and management.

For a deep dive on how pressure ratings are calculated, take a look at our whitepaper on the topic.

Cell Classes

Another way one CPVC differs from another is based on its cell class. Cell classes for CPVC are defined by ASTM D1784 and certified by NSF International, among other organizations.

DID YOU KNOW?

The minimum cell classification of CPVC material is 23447 as defined in ASTM D1784. Lubrizol introduced a higher cell classification of 24448 for Corzan® CPVC.

23447 CPVC vs. 24448 CPVC

To understand the difference between 23447 and 24448 CPVC, we must first discuss how each number in the classification stands for a specific characteristic of the material, according to ASTM D1784:

- The first number (2) is the material designation, where 2 stands for CPVC (1 would stand for PVC, for instance).

- The second number (3 or 4) is the Izod impact strength designation, in which new Corzan CPVC surpasses existing CPVC.

- The third number (4) is for the tensile strength, which must be greater than 7000 psi to receive this designation.

- The fourth number (4) is the tensile modulus, which must be greater than 360,000 psi for this level.

- The fifth number (7 or 8) is for the heat distortion temperature, where upgraded CPVC improves on that of traditional CPVC.

CPVC classified as 24448 has superior impact strength and a higher heat distortion temperature than CPVC with a 23447 designation.

Why Greater Strength and Heat Distortion Temperature (HDT) Matter

Izod impact strength (23447 vs. 24448). The number 4, as opposed to a 3, signifies that the CPVC has an Izod impact strength greater than 5 lbs. (2.27 kg). In fact, 24448 CPVC has an impact strength rating three times that of standard CPVC. Advantages include:

- Pipe will be easier to cut cleanly.

- Fewer pipe and fittings will break and fracture.

- The system’s scrap rate will be lower.

Heat Distortion Temperature (23447 vs. 24448). A superior HDT is required for a number 8 distinction compared to a number 7, which increases the max temperature threshold from 212°F (100°C) to 230°F (110°C). This matters because a superior HDT means:

- The pipe will maintain a straight, professional appearance where standard CPVC may sag or bend.

- The safety factor is increased in the event of a processing excursion.

By improving on the capabilities of existing CPVC with a superior Izod Impact Strength and Heat Distortion Temperature, industrial plants can have greater trust in their CPVC installations.

Corzan® CPVC: A Superior Alternative

The new classification and cell class is another example of how Corzan Industrial Systems continually improves to offer the industrial processing sector the most reliable and highest-performing material on the market. Corzan Industrial Systems’ ongoing research and development gives plants confidence in the materials they specify.

Learn More About How Pressure Ratings Are Calculated

To find out more about the test methods and calculations behind pressure ratings, download our whitepaper, How CPVC Pipe Pressure Ratings Are Calculated. Our product and engineering team dive deep into the processes of the most reputable standard organizations in the world.