Why CPVC Piping is a Sustainable Choice

Many companies have corporate policies regarding sustainability and encourage employees to specify sustainable products provided by suppliers committed to environmental responsibility and improving lives. And even though piping systems may be installed overhead or underground where they are not as visible, they play an important role in helping companies achieve their green goals.

A life cycle analysis can help identify the best pipe material for sustainability -- from raw materials and manufacturing through product use and end-of-life disposal.

CPVC Comes from Sea Water

Chlorinated Polyvinyl Chloride (CPVC) is a thermoplastic produced by chlorinating polyvinyl chloride (PVC) resin. Two-thirds of CPVC resin by weight comes from salt extracted from sea water (brine), which is one of the most abundant resources on earth. Only about one-third of the resin is derived from petroleum resources.

Plastics, overall, account for just 3 percent of the consumption of fossil fuels such as petroleum, coal and natural gas, CPVC is made from by-products that result from refining petroleum.

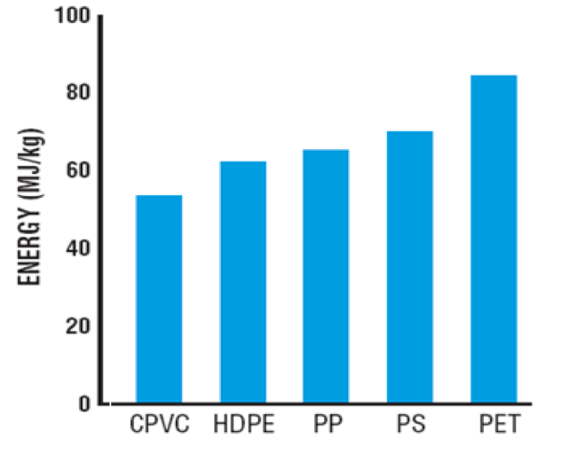

Total energy requirements for CPVC production are lower than for other plastic materials as a result of the lower petroleum content. The graph that follows compares energy consumption for various piping materials.

CPVC = Chlorinated polyvinyl chloride

HDPE = High-density polyethylene

PP = Polypropylene

PS = Polystyrene

PET = Polyethylene terephthalate

In addition, CPVC piping is about one-eighth the weight of metal piping and uses less fossil fuel for freight plus there is no need for fuel-powered equipment to complete installation. A CPVC piping system can generally be installed by two people using low-VOC solvent cement for joining.

CPVC Is A Recyclable Choice

CPVC piping is a thermoplastic, which means it can be recycled during the manufacturing process as well as the after-market of finished products. CPVC systems may be recycled as drainage piping or window profiles.

Specialized recycling firms (country specific) will travel to jobsites to collect piping material and regrind it into pellets and granules, which can be used in products such as floor fillings, floor coatings, cable trays, speed bumps and car mats.

CPVC Piping Will Not Corrode

Many industrial processes involve highly acidic ingredients, water or other substances that can cause piping to corrode. CPVC piping is a specially engineered thermoplastic that is resistant to most acids, bases and salts, decreasing the likelihood of corrosion when used with a range of chemicals. View the Corzan® CPVC Chemical Resistance Table to see how CPVC tests against over 400 chemicals.

CPVC Piping Delivers Reliable Resistance to Biofilm Formation

Biofilm formation begins when microorganisms in water come into contact with a surface and attach to it. Once connected to the surface, the biofilm grows and provides a feeding ground for bacteria to multiply.

An entirely smooth pipe interior is unlikely to support biofilm growth. The Hazen-Williams C-Factor indicates piping material smoothness, with the higher the value, the smoother the material surface. Corzan CPVC piping has a C-Factor of 150 at installation and this value typically remains constant throughout the piping system’s life.

Steel piping, in comparison, has a C-Factor of about 130 to 140 but can deteriorate over time as a result of corrosion, scaling, rust and other processes.

Corzan CPVC Piping Is A Responsible Choice

Corzan CPVC piping materials are safe and have lower energy requirements while producing fewer greenhouse emissions than other piping materials, as reported in the Life Cycle Inventory (LCI) of the Production of Plastic and Metal Pipes for Use in Three Piping Applications. Also, since the plastic piping and fittings do not corrode, they are likely to last longer and reduce the need for replacement materials.

Lubrizol, as the provider of Corzan CPVC technology, is continually committed to identifying new ways to conserve resources and reduce energy usage. Independent life cycle research helps provide insight into how specific products impact the environment, beginning with the raw materials and continuing through manufacturing, product use and disposal.

Corzan Industrial Piping systems have a proven history of performance over the past 60 years and were successfully used in a wide range of industrial applications worldwide. Contact us for a free suitability and technical consultation.

Some of the details in this blog were taken from Lubrizol’s How Proper Piping Material Selection Can Reduce Harmful Biofilm Formation.