Why CPVC Piping Is Safer Than Other Piping Materials

Every company has safety policies to protect its workers, and employee safety should always be the most important consideration when selecting an industrial piping system. Is the piping system functional and reliable? Will it provide the long-term performance expected without bursting or resulting in leaking pipe that can expose workers to dangerous chemicals?

Corzan® CPVC piping includes many properties that make it a safe and durable choice for a range of applications – from chemical and mineral processing plants to power generation and wastewater treatment facilities. Corzan CPVC piping offers superior resistance to corrosive chemicals and reliable performance in the presence of high temperatures and/or elevated pressure for safety and operational efficiency.

Corrosion Resistance So Piping Remains Strong

Many industrial applications include highly corrosive environments that involve the use of aggressive chemicals such as hydrochloric acid, sulfuric acid, caustic soda, ferric chloride and more. Corrosion affects flow rates and efficiency in industrial piping and weakens pipes to the point that the system may fail.

Chlorinated polyvinyl chloride (CPVC) is a specially engineered thermoplastic that is strong and will typically never pit or corrode as it is inert to most acids, bases, salts and some aliphatic hydrocarbons. The aggressive ions that attack the molecules in other piping materials such as metal will not damage CPVC.

Corzan CPVC piping may be used with a range of chemicals. Refer to the Corzan Chemical Resistance Chart to discover how CPVC tests against over 400 chemicals.

Installation Advantages that Help Keep Workers Safe

When metal piping systems are installed, the joints, which require a costly and laborious hot weld process, are often the weakest part of the entire piping system. The joints have the potential to fail and possibly result in employee exposure to dangerous chemicals.

Corzan CPVC piping is generally joined by a solvent cement welding process, which can be performed almost anywhere without heat, flame or hot work permits. Piping system components manufactured to ASTM standards such as ASTM 441, ASTM F438, F439, and ASTM F1970 set the basis for success. Solvent cement fuses the CPVC material together to create joints that are the strongest portion of the entire piping system, offering greater durability than would be possible with the piping or fitting alone. Proper training is key to the project’s success and facilities should insist upon ASME B31.3 bonder qualified bonders only.

Solvent cement has a low VOC (volatile organic compounds), resulting in cleaner air during use and a minute amount of vapors that could trigger health issues for workers, especially those with existing health conditions and allergies.

In addition, Corzan CPVC is lightweight and may typically be handled and installed by two or three people, eliminating the need for lift equipment required to install heavier materials such as metal. Bringing heavy equipment into the plant environment could pose a danger to workers.

Greater Temperature, Pressure and Impact Resistance

Corzan CPVC technology continues to advance, with new technology available from select manufactures that offers a 25 percent higher pressure rating than standard CPVC at 180ºF. Watch how Corzan CPVC piping fared against a competitive product during a burst test.

Comparison Burn Test

Corzan CPVC piping products have built a reputation of superior quality, impact resistance, and consistency that is also confirmed through superior science. In fact, select manufacturers offer the higher cell class of 24448 as defined by ASTM D1784 tested and certified by a third-party testing lab at this higher cell class. Standard CPVC compounds meet the criteria for the lower 23447 cell class.

Corzan has demonstrated long term consistency with a drop impact strength up to three times that of standard CPVC.

Comparison Impact Test

Limited Flammability and Smoke Production

Designers and specifiers must always consider fire performance when selecting piping systems for industrial applications. CPVC, in general, is engineered to limit flammability and smoke production for a safer environment.

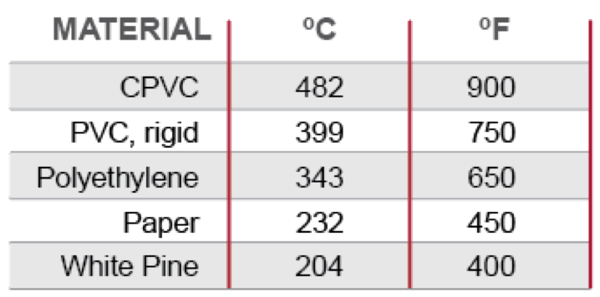

The flash ignition temperature is the lowest temperature at which sufficient combustible gas can be ignited by a small external flame. CPVC’s flash ignition temperature is 900°F (482°C), which makes it far less susceptible to ignition compared to other thermoplastic materials.

Flash Ignition Temperature Comparison

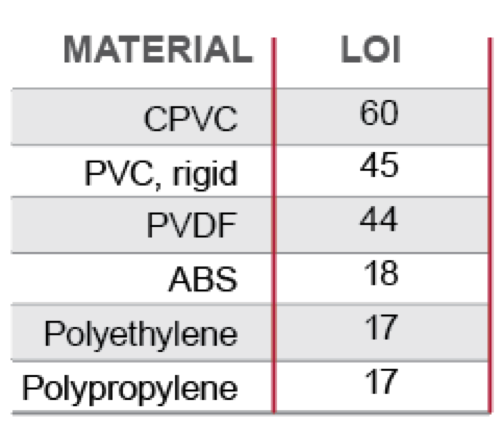

Combustion is only possible when sufficient oxygen is present. A material’s limiting oxygen index, or LOI, is a measurement of the percentage of oxygen in the air that is required for a material to sustain a flame, with the lower the LOI, the greater likelihood a material will burn when exposed to an ignition source. The percentage of oxygen in the earth’s atmosphere varies but is typically about 21 percent.

CPVC has an LOI of 60 percent, which means that it must have nearly triple the percentage of oxygen that naturally occurs in the atmosphere to be able to sustain a flame.

Limiting Oxygen Index Comparison

Corzan CPVC is recognized for its consistent performance in fire situations. The piping system develops a protective char that serves as a thermal barrier to inhibit a flame.

CPVC Burn Test

A Proven Track Record in Challenging Industrial Applications

Corzan CPVC piping systems are an excellent choice for industrial environments, offering outstanding resistance to corrosive chemicals, excellent fire performance, and durability in the presence of high temperatures and elevated pressure. Corzan CPVC piping is readily available from partner manufacturers who offer training and support across the globe.

Corzan Industrial Piping systems have a proven track record of more than 60 years in a wide range of challenging industrial applications worldwide. To learn how Corzan CPVC is the right piping system to help you create a safer environment for workers, contact us for a free suitability review and technical assessment.

Some of the details in this blog were taken from the following Lubrizol materials:

Why CPVC Is Used For Power Generation Plants

What Does It Mean For A Pipe to Be Fire Resistant?