Corzan® CPVC: More Affordable Piping for Hydrogen Peroxide

After decades of use, stainless steel is a known and respected piping material that reliably carries highly corrosive chemicals. Hydrogen peroxide, at high concentrations, is one such harsh chemical. Under 8% hydrogen peroxide is considered non-hazardous and is found in many households in toothpaste, detergents and more. Up to 28% concentration is rated as a Class 1 Oxidizer, but it is still allowed for home use, as in shocking a pool. But above 28%, hydrogen peroxide enters the industrial-only concentrations. 40% hydrogen peroxide is widely used in the pulp and paper industry, 50% hydrogen peroxide has great bleaching properties, making it an attractive essential in the textile industry and for water treatment, 35% or 50% hydrogen peroxide concentrations are used. Stainless steel can handle nearly all concentrations of hydrogen peroxide.

However, the major drawback of using stainless steel is cost. Stainless steel is very expensive. And this isn’t just the initial material expense; it’s also the costs for material transport and for expert installation and maintenance.

For specific, mid-range concentrations of hydrogen peroxide, chlorinated polyvinyl chloride (CPVC) is just as reliable as stainless steel, has greater corrosion resistance and comes at a significantly lower cost. But some engineers hesitate to specify a plastic piping material because, compared to stainless steel, these materials, like CPVC, are still relatively new.

Here, we answer specifying engineers’ common questions about CPVC and caustic chemicals like hydrogen peroxide to help identify use cases where CPVC is an appropriate alternative to stainless steel.

What Concentrations of Hydrogen Peroxide Can CPVC Handle?

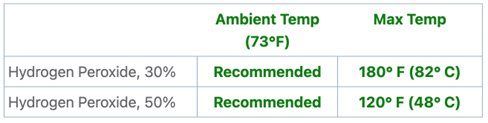

Different CPVC materials will have different tolerances for harsh chemicals. Corzan® CPVC has been tested and shown to reliably perform against 30% hydrogen peroxide to a maximum temperature of 180°F (82°C) and 50% concentration to a maximum temperature of 120°F (48°C). These concentrations of hydrogen peroxide are common to the pulp and paper, textile mill and water treatment industries. In these cases, CPVC performs equal to stainless steel at a much lower cost.

Corzan® CPVC has been tested and is recommended for use with 30% hydrogen peroxide to a maximum temperature of 180°F (82°C)

Corzan® CPVC has been tested and is recommended for use with 30% hydrogen peroxide to a maximum temperature of 180°F (82°C)

and 50% concentration to a maximum temperature of 120°F (48°C).

Is CPVC Really That Much Less Expensive?

Yes, for both the materials cost and labor costs.

The material cost of SS 316 is approximately 5-10% more expensive than SS 304 and approximately 20-30% more expensive than Corzan CPVC.

The labor cost difference is even more massive. The need for high-skilled labor can mean the difference between a job taking two minutes versus a half hour. Welding metallic piping also requires a hot work permit. And the welders required for these high-stakes industrial installations will need advanced skills and expertise, including an AWS certification to weld stainless steel piping. A weld takes one to two hours by the time you cut, prep, join and braze it. By contrast, cutting, prepping and solvent cement welding a Corzan CPVC socket joint takes about 6 to 15 minutes plus cure time depending on the diameter of the pipe being joined.

Is Plastic Really Safe?

When properly specified and installed, CPVC is as safe as any other piping material.

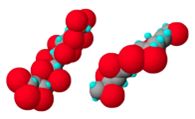

What makes CPVC such a chemically resistant plastic material is its chlorine backbone. The additional chlorine atoms on the polymer chain protect the CPVC from degradation. Someone looking for an inexpensive solution might look at PVC, but that product lacks this extra chlorine protection.

The molecular structure of CPVC (left) contains significantly more chlorine (red) that better protects the chain (grey and blue) than PVC (left).

The molecular structure of CPVC (left) contains significantly more chlorine (red) that better protects the chain (grey and blue) than PVC (left).

The chlorine increases the piping material’s resiliency against harsh material like hydrogen peroxide.

What about Maintenance and Support Prior to Installation?

Stainless steel doesn’t require a lot of maintenance, but what little maintenance it needs can be costly. Especially if the pipe needs to be cut, you’ll incur the same high labor costs as installation. Corzan CPVC also requires little to no maintenance. Unlike metal, it is extremely fast and easy to maintain or even replace, due to its light weight and solvent joining and mechanical joining processes.

As for support, we often hear, “My installers know stainless steel. We’d be learning a totally new process with CPVC.” While this may be true, learning to prepare, install and maintain CPVC is not only an investment in your laborers and facility but it is also a much faster, easier process than learning a high-skill task like welding. Gaining proficiency in solvent welding is a matter of hours, not years like the time needed to be a certified welder. Furthermore, Corzan CPVC is backed by Lubrizol’s value-added global support. Whether in person or online, training and expertise is readily available to assist in making your project a success.

Corzan CPVC for Medium Peroxide Concentrations

Stainless steel is the traditional piping material for hydrogen peroxide. But sticking to tradition for all concentrations of peroxide is an expensive choice when there are more cost-effective and equally reliable alternatives. For 30% and 50% peroxide concentrations, CPVC provides equal reliability at a much better material and total cost.

CPVC’s molecular structure helps it reliably handle harsh chemicals, and Corzan CPVC’s expert formulation and traceability make it the superior material choice. Hydrogen peroxide is just one of the top 10 chemicals that Corzan CPVC is more suitable for compared to metallic alternatives and other plastics.