CPVC Chemical Resistance to Caustic Soda (Sodium Hydroxide NaOH)

Sodium hydroxide, commonly known as caustic soda, is one of the most common industrial chemicals. A versatile alkaline, caustic soda is highly reactive and effective at breaking down certain compounds.

Common caustic soda applications include industries like:

- Pulp and paper for pulping and bleaching processes.

- Wastewater treatment for pH neutralization and wet-air scrubbers.

- Food and beverage as a cleaning agent.

- Personal care, such as soapmaking.

- Power generation for regenerating ion demineralization resin beds.

- Semiconductor for etching, plating acid neutralization and cleaning.

- Aluminum processing applications for dissolving compounds and extracting impurities.

For processing and storage of caustic soda, metals—such as stainless steel or carbon steel—or thermoplastics – such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) – are often used. But the corrosive nature of caustic soda, especially at elevated temperatures and concentrations, can shorten the life of any industrial system.

Corrosion Concerns for Caustic Soda

In general, no material has complete resistance to a chemical or is completely unsuitable. Instead, corrosion resistance is more of a range. As system and environmental conditions are altered, the potential for corrosion changes. For caustic soda, the higher the temperature and concentration, the greater the corrosion risks.

Depending on the concentration and temperature of the caustic soda being handled, metals, including stainless steel can have a shorter service life. PVC can also have a shorter service life if the temperature and concentration of the sodium hydroxide is too high. This can limit its industrial usefulness.

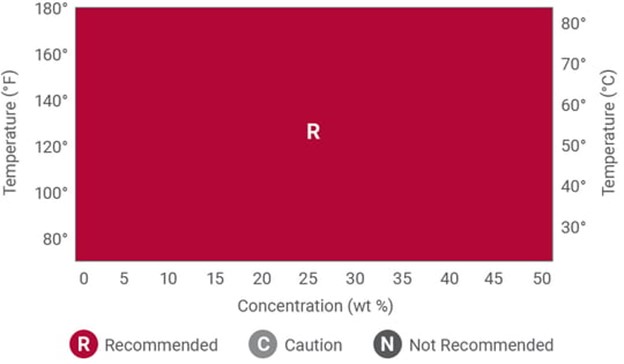

Corzan® CPVC provides reliable resistance against caustic soda in temperatures up to 180°F (82°C) at all concentrations up to 50% (the most common concentration of caustic soda is 50%), which can translate to less maintenance and downtime due to repairs.

When sodium hydroxide attacks CPVC—whether due to the caustic soda’s temperature or concentration, the pressure of the system, its length of use, or a combination of those factors—it occurs through two primary mechanisms:

- General Degradation. When the CPVC resin or compounding ingredients in the material are altered or destroyed by a chemical, general degradation has occurred. This degradation is often characterized by discoloration and blistering of the pipe, sheet, or liner surface.

- Localized Stress Corrosion Cracking. Similar to how stress corrosion works in metals, localized stress in a CPVC material can enhance the effects of chemical attack and encourage crack propagation from the area under stress.

The degree at which degradation and corrosion occur from sodium hydroxide depends on both the solution’s concentration and temperature and the CPVC’s formulation and component manufacturing quality.

CPVC Formulations and Processing Quality

Resistance to sodium hydroxide is heavily dependent on the CPVC formulations and the manufacturer’s processing quality and consistency. Not all CPVC compound is created equal. Inherent molecular qualities of the material differ, altering the final product’s performance.

The importance of CPVC’s chlorine content: What gives CPVC its increased temperature, pressure and flame resistance—in comparison to PVC—are the additional chlorine atoms that protect the carbon backbone of its molecular chain. Though most CPVC resins contain 63 to 69% chlorine, some formulations increase this up to 74%. Additional chlorine content correlates with better resistance to higher temperatures and pressures.

The inclusion of CPVC additives: CPVC resin is often infused with additives to enhance many of the resin’s inherent properties, and notably eases processability. When additives are not included to ease processability, corrosion resistance of the final product may be harder to achieve during processing.

Better quality resin with higher quality additives in the process leads to higher performance against degradation.

Know your manufacturers. Variations in the pressure, temperature, concentration, installation and maintenance of the CPVC material can affect the life expectancy of a system. The full hydrostatic pressure rating of the pipe may not apply to the entire range of temperature and concentration designated.

Caustic Soda Chemical Concentration and Temperature

As the concentration and temperature of a caustic soda solution increases, the rate of attack on the thermoplastic material increases.

The additional chlorine atoms along the polymer chain of CPVC add further protection from harsh chemicals. Corzan CPVC has been extensively tested to show its resistance to sodium hydroxide. A sample is immersed in a caustic solution with some stress applied and held at a constant temperature for 90 days. After that period, the specimen’s surface is observed for possible changes in texture, discoloration, swelling, clouding, tackiness, bubbling or cracking—each signify chemical attack. The sample is also measured for potential weight loss, which is a sign of general degradation.

Corzan CPVC has been used in the field satisfactorily to handle sodium hydroxide solutions and has undergone laboratory testing. In these tests, Corzan CPVC showed good resistance against sodium hydroxide up to 50% concentration at 180°F (82°C), though the expected life of the pipes in a system cannot be determined.

Above that concentration and temperature, signs of stress corrosion cracking and general degradation developed. Although laboratory testing is by nature limited and cannot possibly evaluate the effect of all potential variables on the performance of a complex operational piping system, tests indicate strong performance for common industrial temperatures and concentrations of sodium hydroxide.

Corzan CPVC: A Strong Solution for Caustic Soda

With proper pipe and tank material selection, industrial applications can prolong their useful life. Corzan CPVC is manufactured only by approved partner manufacturers and has been tested against over 500 chemicals and compounds to determine its suitability and to prove its performance against the chemical processing industry’s commonly used corrosive chemicals. Sodium hydroxide is among the top 10 chemicals that specifying engineers choose Corzan CPVC to reliably handle, especially compared with metals, other plastics and generic CPVC.