How Corzan CPVC Meets the Needs of the Global Food Industry

The food and beverage industry depends on processing materials that will not contaminate the supply. When De Marne's stainless steel mustard piping system became compromised, they turn to an alternative material that could withstand the acidic and high temperature conditions of its line.

About De Marne

Since its startup in 1895, De Marne has been a major producer and world exporter of mustard. Named the official mustard supplier to the Royal Family, it’s highly regarded by consumers across the globe. Their products are available in all Dutch supermarkets, and are exported to many parts of Europe, the United States, Canada, Africa, New Zealand and Australia. The De Marne product presence is also expanding in eastern countries, such as Hungary, Czech Republic, Slovakia, Bulgaria, Romania and Poland.

When corrosion was plaguing a previous system of piping and tanks, De Marne found a material that has now delivered reliability for more than a decade.

The Challenge with Stainless Steel

When first in production, De Marne produced and stored mustard through stainless steel 316 piping and tanks. However, the material gradually corroded due to:

- The interference of acids, specifically vinegar.

- The consistent processing temperature of 158°F (70°C).

Over time, this led to compromised processing conditions, reducing the production and distribution of mustard.

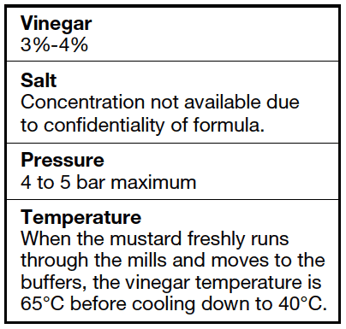

Application Details

The Solution: Corzan® CPVC

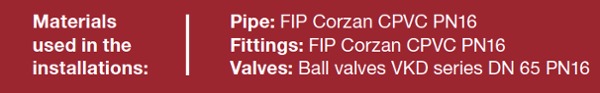

Seeking a piping system with better outcomes than stainless steel, De Marne partnered with Akatherm in the Netherlands to install Corzan® CPVC Industrial Systems manufactured by FIP.

Superior Corrosion and Temperature Resistance

The Corzan CPVC Industrial System, supplied by the two companies of the Aliaxis Group, maintained production consistency and prevented corrosion from acids and changing temperatures. The temperature and acid resistant properties of Corzan CPVC represented a major advantage over the previous material, stainless steel.

See the chemical resistance of Corzan CPVC for different industrial processing applications below.

PVC was also considered, but quickly ruled out. The process working temperature can rise up to 158°F (70°C), which is above the maximum temperature limits of PVC.

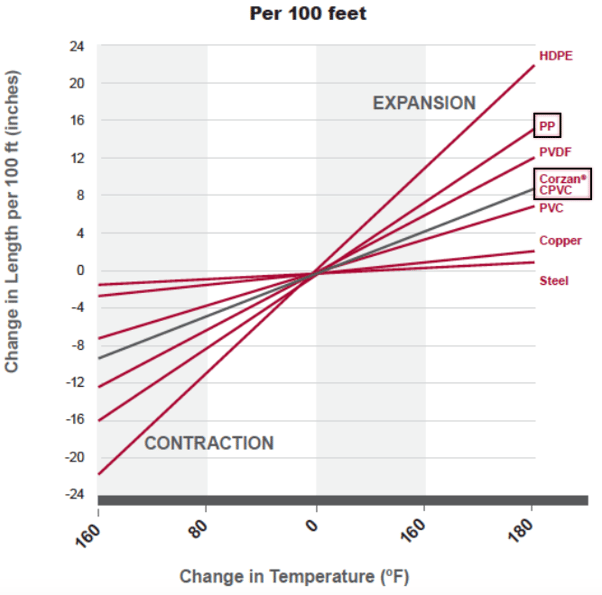

Lower Coefficient of Expansion than Polypropylene (PP)

Another advantage they discovered with choosing Corzan CPVC is its low coefficient of expansion. This means that CPVC requires less hangers and compensators compared to PP, whose coefficient of expansion is significantly higher.

Nearly Eliminates Production Down Time

In addition, the longer service lifetime and ease of maintenance nearly eliminates production down time due to piping issues.

The Bottom Line: Corzan® CPVC Outperforms Alternatives

All these factors led to the choice of Corzan CPVC as the best solution, as it surpassed previous problems of corrosion, and ultimately increased production, quality and reliability. It was also the best technical solution, providing cost reductions, higher quality and long-term reliability.

The Result: No System Failures in Over a Decade

The Corzan piping system was installed in 2004 and 2005 across the factory to replace stainless steel. At least 1.24 miles (2 km) of piping has been installed where chemical resistance against vinegar was necessary.

The tanks are made of stainless steel or FRP where the mustard is stored or mixed. In the final mustard, the concentration of vinegar is considerably lower and hence represents less of a corrosion problem for the storage tanks.

The Corzan piping is in constant use with vinegar and therefore does not require cleaning. The stainless steel piping, however, must be cleaned regularly, though only at 104°F (40°C). Usually the steel system is washed simply with water and occasionally a small amount of vinegar is added to act as a cleaning agent.

Corzan CPVC Industrial Systems met potable water approvals and confirmed compliance with the EU regulation on migration limits.

Jan Hingstman, the Technical Service Manager at De Marne’s production site in Groningen, confirmed that during the past 12 to 13 years, since its original installation in 2004 and 2005, no failure of Corzan piping has occurred. The only change to the existing Corzan piping system was in 2007 and 2008 when the pipe diameter was increased to accommodate for a larger product flow rate in the pipe.

"The CPVC Corzan Industrial Systems runs without failure the minute it's installed."

- Jan Hingstman, Technical Service Manager at De Marne

Is Corzan CPVC Right For Your Application?

De Marne is just one example of success in the nearly 60 year track record of Corzan CPVC technology. If you want more information about how Corzan CPVC delivers reliability to industrial processing applications, our team of product and engineering specialists are happy to follow up or provide for a free consultation.