How Corzan® CPVC Piping Pays for Itself in Mineral Processing Plants

Mineral processing plants require safe, reliable piping systems that ensure facilities remain operational and more productive over the long term. But, mineral processing facilities present tough challenges for piping systems, including the presence of aggressive chemicals, temperature extremes, continual exposure to ultraviolet radiation and more.

Corzan® CPVC piping systems provide payback with a balance of properties that improve reliability and user confidence while reducing capital and life-cycle costs. Corzan CPVC piping surpasses other piping materials for performance and cost savings in electrolysis operations, electrowinning, electrorefining, acid service lines, tailing lines, gas vent scrubbers, froth flotation operations and wastewater treatment plants.

Resists Corrosive Chemicals and High Temperatures

Whether a mineral processing facility extracts precious materials from the ground or processes raw materials after excavation, corrosion is an ongoing challenge and has the potential to slow flow rate, decrease pressure and weaken pipes to the point of failure. Mineral processing plants use reagents such as sodium cyanide, caustic soda and sulfuric acid to separate metals from ore, which is why facilities cannot rely on metal piping as the chemicals will attack the metal.

Chlorinated polyvinyl chloride (CPVC) piping is a specially engineered thermoplastic pipe that is strong and eliminates internal and external corrosion as CPVC is inert to most acids, bases, salts and some aliphatic hydrocarbons. Aggressive ions that attack the molecules in piping materials such as metal will not damage CPVC.

Some integrated mineral processing facilities have caustics and acids that will degrade many piping system materials. Corzan CPVC piping will withstand these chemicals, as confirmed by the comprehensive Corzan Chemical Resistance Chart, which shows how CPVC tests against over 400 chemicals. Corzan CPVC piping systems are applicable for chemical injection lines, distribution lines and process lines.

Sometimes, chemical processes have a process temperature that operates on the upper limits of Corzan CPVC piping’s typical working range. Dual laminates may be specified for these situations, combining Corzan CPVC’s superior chemical resistance with the mechanical strength of fiber reinforced plastics (FRP), effectively extending the operational temperature range.

The FRP exterior in a dual laminate piping system provides the structural strength, so warping or sagging caused by high heat exposure becomes less of a concern. Many applications are using Corzan CPVC in dual laminates at temperatures 20°F to 25°F higher than what the piping system is designed to handle.

Withstands Weather Extremes and UV Exposure

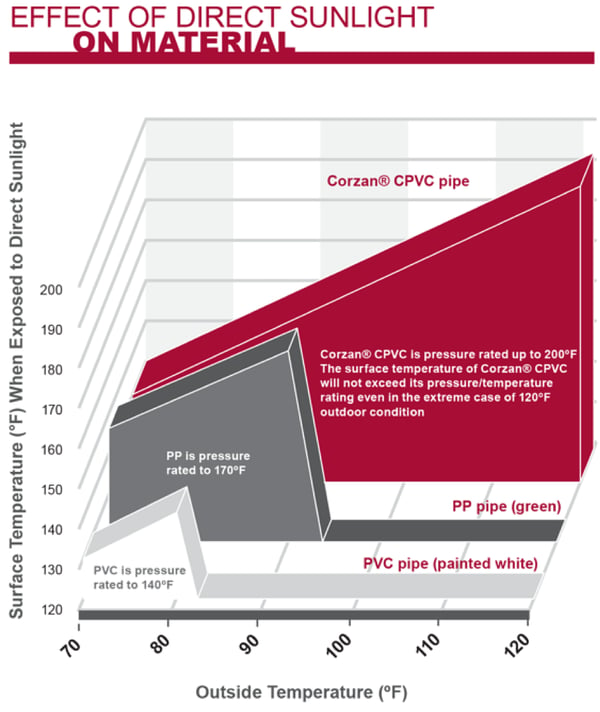

Mineral processing plants are often located in hot zones such as southeast California, Nevada and Latin America where temperatures may soar as high as a sustained 110°F during the day. Design engineers are sometimes reluctant to specify plastic piping that will be exposed to high temperatures and direct sunlight because they are concerned the material will dry up, crack and leak. Ultraviolet radiation is a tremendous issue. which is why some designers require that plastic piping material be painted or specially tested to confirm it will withstand high temperatures and direct sunlight.

Corzan CPVC contains a significant concentration of carbon black and titanium dioxide, which are excellent ultraviolet-blocking agents that effectively protect the polymer backbone from the effects of ultraviolet light.

In addition, Corzan CPVC is pressure rated up to 200°F, and the piping system’s surface temperature will not exceed its pressure/temperature rating even in extreme outdoor conditions of 120°F. Tests and customer installations verify Corzan CPVC piping systems’ pressure-bearing capability and reliability after prolonged UV exposure,

Depending on the installation, extended exposure to UV light can cause a gradual reduction in CPVC piping material properties. Corzan CPVC piping and fittings may be painted with water-based acrylic latex paint in applications that require additional protection from sunlight.

Even though piping materials inherently become more brittle in low temperatures characteristic of geographical areas such as Canada, Corzan CPVC has no recognized absolute minimum temperature that the piping system can endure. This is why you should speak with Corzan product and engineering experts when designing or installing Corzan CPVC piping in a cold weather environment.

Corzan CPVC piping’s highest in class impact strength also helps ensure long lasting, reliable performance – whether piping systems are exposed or buried underground.

Corzan CPVC Impact Test

Performs In Wastewater Treatment Facilities

Mineral processing plants typically operate wastewater treatment facilities, which are highly corrosive environments. Corzan CPVC piping systems may be installed anywhere in a wastewater treatment facility to convey a fluid or other medium, with most of the aggressive chemicals used during water treatment processes compatible with CPVC.

Corzan CPVC piping systems also resist scaling and fouling. Minerals can form deposits on piping materials – most notably metal – and cause corrosion and plugging over time. CPVC’s smooth surface, however, is unaffected by corrosion.

At installation, Corzan CPVC has a Hazen Williams C Factor of 150, with the higher the C Factor, the smoother, more consistent the material surface and the greater the resistance to mineral deposits and biofilm. CPVC piping’s C Factor is maintained throughout most of the product’s life. New stainless steel, in comparison, has a C Factor of about 130, which can drop below 100 after years of use.

Offers a Proven Track Record

Corzan CPVC piping systems are an economical choice for mineral processing environments, offering outstanding resistance to corrosive chemicals and reliable performance in the presence of high temperatures and prolonged exposure to sunlight.

Corzan CPVC piping systems offer over 60 years of proven success in a range of challenging applications, providing an excellent balance of properties to boost user confidence while reducing capital and CPVC life-cycle costs. To learn more about how Corzan CPVC prevents costly downtime and helps mineral processing plants remain operational and more productive, contact us for a free suitability review and technical assessment.