Why Choose CPVC and Dual Laminates to Mitigate Corrosion

The chemical processing industry (CPI) continues to be a tough environment for creating safe composite structures that mitigate corrosion degradation. Today, more design engineers and material specifiers are calling for fiber reinforced plastics (FRP) in both new and replacement equipment used in chemical processing operations.

B&D Plastics is a fabricator of dual laminate structures. Their unique fabricating process allows for the handling of fluids at very high temperatures and is impervious to corrosives.

B&D Plastics is a fabricator of dual laminate structures. Their unique fabricating process allows for the handling of fluids at very high temperatures and is impervious to corrosives.

To develop products capable of standing up to its customers’ demanding applications, B&D Plastics specifies Corzan® chlorinated polyvinyl chloride (CPVC) manufactured by IPEX USA.

Why Corzan® CPVC for Dual Laminates?

The company relies on Corzan CPVC because of its track record of consistency, reliability, and problem-free lifespan. In addition, the material effectively resolves the most common customer issues by providing corrosion resistance and reliable, long-term handling.

Corrosion Resistance

Corrosion is one of the most costly issues facing plants that handle chemicals like hydrochloric acid (HCl). This substance causes general corrosion, pitting and stress-corrosion cracking of austenitic stainless steel, such as 316. In fact, 300-series stainless steels can even be attacked by diluted HCl. Although there may be low concentration and low temperature combinations that are acceptable in some specific cases, 316 stainless steel is not recommended when hydrochloric acid is present.

Long-Term Handling

The industry has struggled to find a long-term solution to handling HCl in various concentrations for a multitude of applications. The traditional choices of carbon and stainless steel aren’t ideal, especially in the long-term. Microbiologically Influenced Corrosion (MIC)—also known as microbial corrosion or biological corrosion—can cause deterioration of the metals as a result of the metabolic activity of microorganisms. Even lined carbon steel, HDPE and FRP have resulted in process leaks and premature failure when used with the following corrosive substances:

- Sulfuric acid

- Sodium hydroxide (caustic soda)

- Cell liquor (brine, sodium hydroxide)

- Sodium chloride (brine)

- Sodium hypochlorite

- Hydrochloric acid

- Demineralized / deionized water

B&D Plastics understands that reliable systems begin with the consistency and quality of their components, which is why they utilize Corzan CPVC technology in a variety of their vessels, components, and pipelines.

The precise and highly skilled fabrication completed at B&D requires consistent raw materials. Reliable raw materials from Corzan Industrial Systems and effective fabrication by B&D Plastics align impeccably to manufacture the challenging geometries required to meet the demanding tolerances their customers require.

View the Corzan Chemical Resistance Table for CPVC's compatibility with 400+ chemicals.

Lubrizol’s Corzan Technology displays the necessary mechanical strength and chemical resistance to make it a solution for B&D Plastics’ composite structures.

Tom Reeves, President and CEO of B&D Plastics

Manufacturing World-Class Dual-Laminate Vessels

B&D Plastics leverages Corzan technology to enhance the structural integrity of its fabricated composite structures, specifically scrubbers, towers, evaporators, precipitators, clarifiers, and piping.

B&D Plastics leverages Corzan technology to enhance the structural integrity of its fabricated composite structures, specifically scrubbers, towers, evaporators, precipitators, clarifiers, and piping.

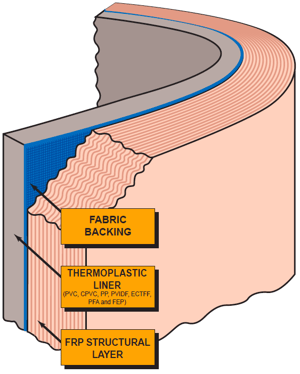

The company employs CAD and a unique, thermo-forming molding process for corner radius and dished-head designs that insure the integrity of liner materials in key stress points. This is combined with an advanced bonding technology, which provides a stronger bond between the thermoplastic liner and the fiberglass structural shell than is possible with lined metal alloys.

Corzan is the only material we recommend when we see applications where CPVC may be used. Corzan has an established track record and, in our business, that is paramount. Combined with Corzan’s technical support and ease of use in our vessels, it allows us to meet our production schedules.

Tom Reeves, President and CEO of B&D Plastics

With Corzan CPVC manufactured by IPEX USA, B&D Plastics recently designed a piping system for 2,000 feet of chlorine cell liquor headers operating at 160°F (71.1°C). These headers consisted of components varying from 6 in. to 12 in.

B&D Plastics chose machine butt fusion of Corzan material for a corrosion resistant liner in conjunction with a Hetron FR992 fire retardant resin system for the fiberglass structural shell.

B&D Plastics chose machine butt fusion of Corzan material for a corrosion resistant liner in conjunction with a Hetron FR992 fire retardant resin system for the fiberglass structural shell.

Because of the skilled manufacturing and careful material selection of these components, the company’s customers can rest assured that their below-deck headers will remain maintenance free for years to come.

When an application calls for chemical resistance in process equipment, customers rely on B&D Plastics, and B&D relies on IPEX and Corzan CPVC.

Need Specification, Technical or Engineering Support?

From spec writing to installation, our team of product and engineering experts are here to provide the information, advice and training needed to select and integrate the best piping solution for your application. Request a free consultation.