Corzan® CPVC: Vertical Pipe Support Methods in High-Rise Construction

In multi-story construction, designers not only need to consider expansion and contraction for horizontally run pipe, but also the design and installation of the vertical piping. One school of thought when installing Corzan® CPVC for hot water riser systems is to use expansion loops similar to horizontal installations to account for thermal expansion.

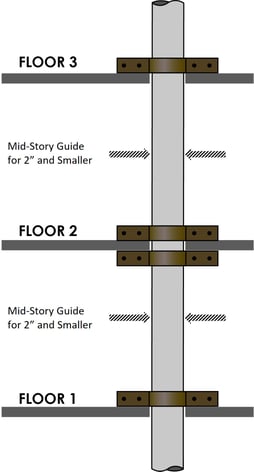

However, another common installation practice eliminates expansion loops, which add cost and time to the installation process, and instead uses a restraint configuration which confines the thermal expansion to two-floor sections. This alternate method calls for applying single pipe clamps on odd floors, double pipe clamps on even floors, and adding mid-story guides on pipe of two inches in diameter or less.

To determine the validity of this approach, and the limits of our product in this application, Lubrizol Advanced Materials asked Stress Engineering Services to provide a detailed computational analysis of the stresses and strains imparted to a hot water riser system comprised of Schedule 80 Corzan CPVC pipe in five different pipe diameters, when installed according to this restraint configuration. The pipes were assumed to be installed at cool or cold temperatures and then filled with hot water to cause thermal expansion and changes to mechanical properties of the pipe. These stresses and strains were compared against published limitations of the material to determine the adequacy of the practice, balancing the needs for pipe motion, positional requirements and installation costs.

The analysis, “Evaluation of Corzan® CPVC Hot Water Riser Systems,” provides an overview of the mechanics of pipe deflection and stress. The amount of deflection determines whether the riser will come in contact with the interior of the walls due to buckling, and stresses are the primary indicator of potential failure of the riser. Stresses are categorized in three ways:

- Pressure stress – In both top-feed and bottom-feed riser systems, gravity acts to increase the pressure of the water in the pipe in the lower stories. This increasing internal water pressure results in stress and strain in the CPVC pipe wall, primarily in the “hoop”, or circumferential direction, eventually leading to rupture. A secondary form of pressure stress is longitudinal, or axial, created by restrained thermal expansion of the pipe, and is either tensile or compressive. Longitudinal stress cannot progress unchecked as force-generated stresses can, being naturally self-limiting.

- Thermal stress – All materials experience thermal expansion where a change in temperature results in a change in size. Corzan CPVC has a coefficient of thermal expansion of approximately 3.4e-5 in/in/°F, meaning that for every increase in temperature of 1°F, a piece of CPVC will grow .0034%. This expansion is as much as five times greater than that of the building’s steel structure. Left free to grow uninhibited, this thermal expansion would not result in any detrimental stresses, only a change in dimension. However, if the pipe growth is restrained with clamps or loops, the thermal expansion results in stress in the pipe.

- Creep strain – Creep strain is the mechanism where materials will deform under a sustained load over time. A function of stress, time and temperature, creep causes material degradation and can result in the derating of the riser for long term use at elevated temperatures.

Report Validates Use of Riser Clamps Over Expansion Loops

To evaluate the levels of stress in the CPVC risers and determine the adequacy of the installation practice, Stress Engineering performed a series of computer analyses. Generally, these analyses were used to calculate the amount and nature of stress generated in a riser under a given combination of temperature and internal pressures up to and including 200 psi.

The Stress Engineering analysis concludes that the riser clamp installation practice for Corzan CPVC hot water riser systems results in acceptable stress states for installation temperatures down to 30°F, as long as the internal pressure rating of the riser is not exceeded for a given expected internal temperature of 140°F – up to and including a 50-year service life.

This finding is applicable to installations for any building height, provided the pressure remains within approved design parameters based on the operating temperature, and the diameter and schedule of the pipe. This conclusion backs up the years of successful installation of riser clamping systems and is supported by guidance provided in piping design code ASME B31.3 as well as ASME BPVC Section VIII.

Read the report in full by clicking the link below.