CPVC Do's and Don'ts for Hydronic Applications

Confidence is one of the greatest assets an industrial piping system can offer – confidence the system will perform as expected.

Corzan® CPVC pipe, fittings and valves are designed to meet the temperature and pressure requirements of hydronic applications and withstand the internal stresses that result from conveying fluids over time at various temperatures. When designed, installed and operated according to manufacturer recommendations, Corzan CPVC piping and fittings instill confidence by providing reliable, long-term performance.

“Dos” for Designing CPVC Piping for Hydronic Applications

Adhering to the following guidelines will help ensure CPVC thermoplastic piping systems are designed and installed correctly.

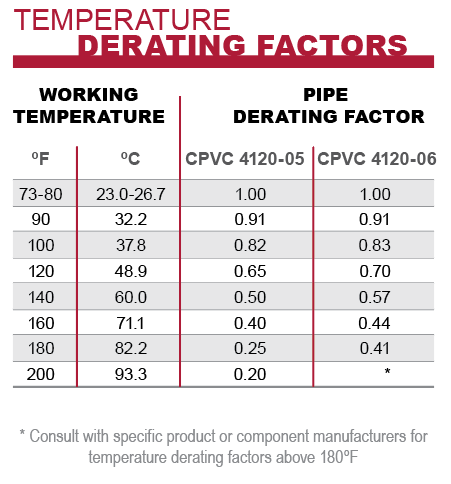

- Select a piping system with a maximum operating temperature of 200°F. Corzan CPVC piping may be installed in systems with an operating temperature up to 200°F. When working with temperatures from 73°F to 200°F, design criteria require the system’s operating pressure to be de-rated according to the pipe size used. Pressure ratings vary with schedule, pipe size, compound type and temperature.

- Verify antifreeze compatibility and percentage. Corzan piping systems are suitable for handling propylene glycol solutions up to 35 percent, methanol solutions up to 10 percent and ethylene glycol or glycerin solutions at any concentration. Always confirm the compatibility of other types of antifreezes or heat transfer fluids with the manufacturer before using.

- Compensate for the expansion of water and antifreeze. This is an industry best practice for all piping materials since water and antifreeze both expand when heated. Water expands at 4 percent and antifreeze expands at up to 12 percent. Using an expansion tank properly designed for the volume of the system and the type of fluid being conveyed will compensate for these increases.

- Verify the compatibility of all boiler cleaning fluids or additives. Corzan CPVC has been used for decades in industrial process water applications handling chilled and boiler water treated with corrosion inhibitors, biocides and other water treatment chemicals similar to those used for recirculating HVAC systems. No detrimental effects were observed when these chemicals were applied at their recommended rates. Corzan CPVC is not recommended for dispensing such chemicals in concentrated form into recirculating systems.

- Use only CPVC x metal threaded adapters. This is a recommendation for all systems with heated water. Expansion and contraction occur as the water is heated, and this movement could create a leak on plastic threads.

- Confirm pumps and other components are properly supported. Pumps are heavy and vibration that occurs during pumping can cause movement, which is why it is important to separately support pumps and other heavy metallic products such as expansion tanks when using plastic piping.

- Verify the compatibility of all ancillary products used during piping system installation. Lubrizol makes this recommendation for all piping products. The Lubrizol FBC™ System Compatibility Program eliminates the guesswork associated with researching the chemical compatibility of construction products that will be used during installation.

“Don’ts” for Designing CPVC Piping for Hydronic Applications

Pay heed to this list of don’ts to help prevent future piping system failure.

- Don’t use 100 percent CPVC threaded adapters. Use metal threaded adapters instead. Expansion and contraction occur as the water is heated, and this movement could create a leak on plastic threads.

- Don’t use compression fittings. Compression rings do not bind as well to plastic pipe as they do to copper and adding heated water can loosen the connection.

- Don’t use CPVC pipes or fittings to support pumps or other components. Pumps are heavy and vibration that occurs during pumping can cause movement. It is important to properly support pumps and other heavy metallic products such as expansion tanks when using plastic piping.

Specifying a Reliable and Efficient Piping System

Corzan SCH 80 piping is available in sizes ranging from ¼-inch to 24 inches to meet the specific needs of hydronic applications. Corzan CPVC piping has proven its ability to meet hydronic system needs in various commercial and industrial applications worldwide for over 60 years.

Contact a Corzan engineering expert or one of our partner manufacturers for engineering guidelines to specify a reliable and cost efficient piping system or to schedule a free process suitability review and technical assessment.

Details for this blog were taken, in part, from the following:

https://www.corzanplumbing.com/hvac-design-guide-download

https://www.corzanplumbing.com/blog/piping-solutions-hvac-projects

https://www.corzanplumbing.com/blog/switching-to-corzan-cpvc-for-hvac-projects