How to Better Regulate Cooling Towers to Maximize Efficiency

Summertime is filled with images of beautiful blue skies, green grass, and picturesque sunsets – all part of a blistering hot environment in much of the U.S. During the summer heat, we like our drinks to be cold and our homes, offices and cars to be cool. Did you ever think about how this is accomplished?

Engineers have created heat transfer mechanisms to control the temperature of water and air. These two extremely powerful forces of mother nature collide in a technology that is used around the globe in the form of cooling towers. Yes, these are the big boxes we see emitting condensation into the air as we approach power facilities or the structures that create a slight mist overhead as they churn and mix air and water in an attempt to move the temperature of the water to a cooler state.

Nearly every business segment utilizes cooling towers – power generation plants, chemical processing facilities, dairy plants, office buildings, schools, universities and more. Cooling towers are traditionally built of wood, concrete and sometimes composites.

Many facilities manage their own cooling towers and chiller systems, utilizing service companies to oversee their systems in the same way that home owners hire a pool company to clean and maintain their swimming pools. No matter who assumes responsibility for system management, cooling towers include unique and challenging characteristics that can threaten their system performance.

Cooling tower piping systems, therefore, should be designed to help regulate process systems for greater efficiency and reliability, with features and benefits that achieve lower life-cycle costs.

How Cooling Towers Operate

Cooling towers dissipate heat from recirculating water used to cool chillers, air conditioners and various industrial processes. Heat is cast off into the environment via evaporation, with water that is lost from the cooling tower replaced by make-up water.

“Cycle of concentration” is an important measurement used to evaluate cooling tower operation. The cycle of concentration is measured by calculating the ratio of dissolved solids in the blowdown water compared to those in the make-up water. Dissolved solids enter the cooling system via the make-up water and exit the system in the blowdown water, so the cycles of concentration are nearly equal to the ratio of the volume of make-up water to blowdown water.

Maximizing the cycles of concentration can increase water efficiency by minimizing blowdown water quantity and reducing the amount of make-up water required as part of the process. This can only be accomplished, however, within the constraints of the make-up water and the cooling water chemistry. Dissolved solids increase as the cycles of concentration increase and have the potential to result in corrosion and scaling issues unless carefully controlled.

The number of cycles of concentration a cooling tower system can handle will depend on the make-up water quality and cooling tower water treatment procedures.

Corrosion and Scaling Issues

Cooling towers are designed to handle large quantities of water, and the water requires disinfection. A variety of highly corrosive chemicals are used during cooling tower processes and maintenance, including hypochlorite, caustic soda, sulfuric acid, sodium sulfite, ferrous chloride, hydrogen sulfide and more. These chemicals are highly corrosive and compromise the integrity of most metal piping systems.

Metallic systems may experience pitting corrosion, with tiny pits forming along the length of the pipe that diminish the pipe wall thickness and reduce its pressure bearing capabilities. Crevice corrosion forms as ions in the fluid gather in crevices around welds, flanges and other areas where the pipe is connected. The resulting buildup can quickly degrade the piping material and cause leaks at joints and welds.

Sulfite-based oxygen scavengers are used to remove all traces of oxygen, which is a catalyst for corrosion. Phosphates added to bind calcium ions and prevent them from attaching to metal parts result in scaling that reduces process efficiency by constricting piping and increasing pressure. Corrosion and scaling decrease pumping efficiency, and metal pieces that flake off due to corrosion can contaminate the fluid.

Cooling towers will want to avoid microbial contamination, which accumulates through microbial slimes comprised of masses of microscopic organisms and their waste products. Microbial slime reduces the efficiency of heat transfer because it serves as a layer of insulation. It can also be corrosive to metallic piping.

Microbial organisms grow and multiply when stagnant water is present, such as when systems are turned off after normal hours of operation or shut down for repairs. Facilities should avoid standing water by specifying reliable materials and closely controlling processes. Selecting a piping system with inherently smoother, consistent surfaces will prevent the clinging and buildup of biofilm and other microbial organisms.

A Piping System to Increase Cooling Tower Efficiency

Whether a facility manages its own cooling tower or contracts with an outside company, the system can benefit from the installation of high-performing chlorinated polyvinyl chloride (CPVC) piping to meet ever-increasing application demands. Corzan® CPVC is a high-performance thermoplastic designed to provide outstanding resistance to many of the corrosive chemicals used at temperatures up to 200°F (93°C) during cooling tower disinfection and maintenance processes.

Corzan CPVC piping and fittings provide superior, long-term resistance to acids, bases and salts, including seawater and demineralized water. The Corzan CPVC Chemical Resistance Chart details the material’s compatibility with over 400 chemicals. Corzan CPVC also includes smoother, consistent surfaces that resist microbial buildup.

In addition, the material offers the advantages of superior mechanical strength and the highest impact resistance–24448 cell class up to an 8-inch diameter as defined by ASTM D1784—of any CPVC piping.

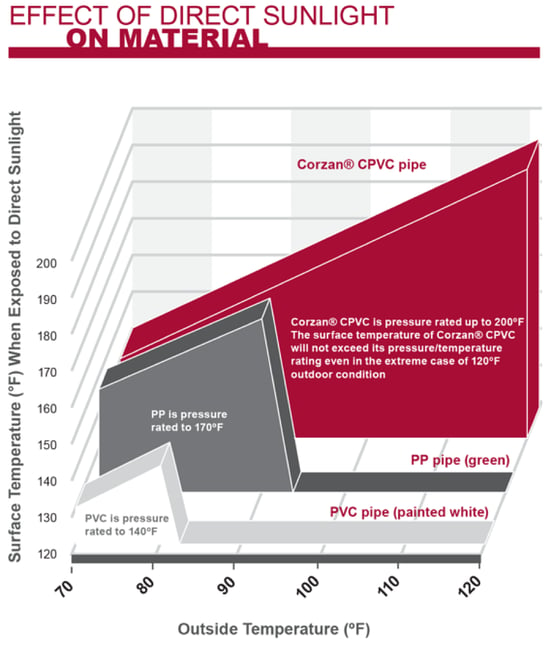

And, unlike other thermoplastics such as PVC and polypropylene, Corzan CPVC can take the heat of extreme sunlight, which is essential for facilities that install their piping systems partially or completely outdoors. Significant quantities of carbon black and titanium dioxide block ultraviolet rays by protecting the pipe’s polymer backbone. The additives also ensure the piping material retains its pressure bearing capability even after extended UV exposure.

The illustration that follows shows the effect of direct sunlight on the Corzan CPVC surface temperature.

At 230°F, Corzan CPVC Cell Class 24448 materials have the highest heat distortion temperature (HDT) in accordance with ASTM D1783 of any certified CPVC material.

A Piping System to Lower Installation and Life-Cycle Costs

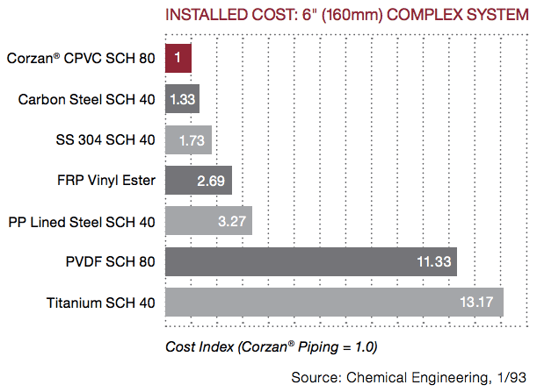

Corzan CPVC offers greater efficiency during installation and maintenance compared to metal piping for time and cost savings, The chart below shows the cost of installing Corzan CPVC compared to metal and other materials.

Installing metal piping is especially time consuming and labor intensive as it involves a complex welding process that requires a designated welding area, an experienced certified welder, costly hot work permits and weld x-rays.

Metal piping is inflexible and even subtle adjustments to the system’s alignment may require expensive reconfigurations. With the system approximately six times the weight of CPVC, installation will likely require more laborers and heavy equipment to move and hoist the piping system into place.

Corzan CPVC, on the other hand, is more flexible and easier to maneuver than metal piping, which facilitates installation and maintenance, decreases downtime and reduces worker strain and injury. Corzan CPVC piping is generally joined by a solvent cement welding process, which can be applied anywhere without heat, flame or hot work permits. Solvent cement fuses the CPVC material together to economically create joints that are the strongest portion of the entire piping system. In addition, Corzan CPVC may be joined with mechanical joining systems.

Corzan CPVC piping is available in diameters up to 24 inches to satisfy most power plant requirements. Piping system hangers and supports must be correctly spaced to help maximize performance. Allowing too much space between supports can add unnecessary stress to the system and result in deflection and sagging. Permitting too little space between supports boosts installation costs.

Minimal training will be required to learn how to properly install Corzan CPVC piping. However, it is highly recommended that any installers be ASME B31.3 qualified in the solvent welding process. Once installed, the system will require little or no maintenance since it will not corrode or scale, resulting in reliability and lower life-cycle costs compared to metal piping.

A Piping System with a Track Record of Success

Corzan CPVC piping systems surpass other materials for cooling tower efficiency based on performance and cost. Corzan Industrial Piping systems have demonstrated their operational capabilities for over 60 years in a wide range of industrial environments worldwide.

To learn how Corzan CPVC will increase efficiency in cooling tower applications and improve bottom-line performance, visit the Corzan CPVC website and contact us for a free suitability review, a technical assessment and training details.

Some of the information in this blog was taken from the following Lubrizol resources:

https://www.corzan.com/blog/why-cpvc-is-used-for-power-generation-plants

https://www.corzan.com/en-us/cpvc-use-in-power-generation-plants