How to Increase Efficiency in Boiler Systems

When the snow flies this winter, we’ll remain comfortable inside our homes, office buildings or the industrial facilities where we work because of the boiler systems that provide heat. Industrial hot water boiler systems that generate thermal heat are similar to the heating boilers found in the basement or crawl space of most homes – except they are much larger to accommodate the application needs. Industries such as food processing, for example, require significant thermal energy to boil or heat raw foods during processing.

Boiler feed water systems treat and transport water to the boiler; the feed water must be ultra-pure to ensure system efficiency. A variety of very strong chemicals are used to treat boiler feed water to remove corrosive substances, balance pH levels and limit boiler water conductivity. Installing the right piping system material is essential to prevent corrosion to pipes and contamination, maintain boiler system strength and facilitate flow.

Prevent Corrosion

Metal piping used as part of industrial boiler systems stands up fine to clean water processing applications with a neutral pH. But metal will corrode and degrade relatively quickly if the fluid’s pH extends much beyond neutral (7).

Corrosion can result in any number of problems. Pitting corrosion creates tiny pits along the length of the pipe that diminish the pipe wall thickness and reduce its pressure bearing capability. Crevice corrosion occurs when ions in the fluid concentrate gather in welds, flanges and other types of pipe connections, causing a buildup that can degrade material quickly and cause leaks.

Slowed flow rate often results as corrosion places greater demand on pumps within the system. And, fluid contamination ensues as corroded pieces of metal break off.

Corzan CPVC® piping systems offer a high level of corrosion resistance compared to metal systems. Corzan CPVC is a highly engineered thermoplastic designed to provide outstanding, long-term resistance to acids, bases and salts, including seawater and demineralized water.

The Corzan CPVC Chemical Resistance Chart provides the material’s compatibility with over 400 chemicals. The material also has a lower affinity to scaling than metal.

Lower Oxygen Permeation

Oxygen that permeates a piping system wall can cause boiler system components such as steel pumps and boilers to corrode. The sludge that results consists of a fine grain metal oxide that is usually easily transported with the water. This sludge builds up over time and leads to circulation disturbances and/or other corrosion-related problems.

The piping material installed must allow no oxygen to enter the closed loop heating system. Plastic piping materials such as polypropylene (PP) and polyethylene (PE) are not impermeable, and the amount of oxygen passing through the pipe wall to enter the heating system will increase as the temperature rises.

Corzan CPVC piping offers superior permeation resistance, as confirmed by the following figures, which result from oxygen permeation and diffusion testing with CPVC films:

| Oxygen Transmission Rate | 7.2 cc/(m2-day) |

| Permeation Coefficient (P) | 180 cc-mil/(m2-day-atm) |

| Diffusion Coefficient (D) | 6.25x10-9 cm2/sec |

Oxygen permeation resistance is a major difference between Corzan CPVC and polyolefins such as PP and PE.

Select No or Low Leachable Piping

Leaching occurs when impurities from the pipe surface contaminate the fluid, causing reduced mechanical strength in the piping system that can result in structure failure. Because the system’s original shape and dimensions often remain the same, the extent of corrosion caused by leaching is often difficult to detect.

Metal piping materials are vulnerable to leaching, which is why metal piping systems are not recommended when fluid purity is essential. Corzan CPVC delivers superior reliability at increased pressures and temperature.

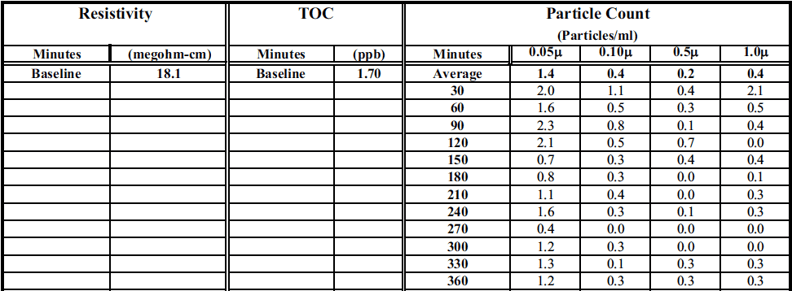

Balazs™ Analytical Services conducted a dynamic leach analysis on a sample of 1/2-inch SCH 80 Corzan CPVC pipe assembly, plus the solvent cemented coupling. The pipe was examined with 18.1 mohm-cm water for approximately four hours at ambient temperature and a flow rate of approximately one gallon per minute.

Online particle measurements were recorded every 30 minutes, with total organic carbon (TOC) readings recorded every six minutes. Grab samples of anions, cations and trace elements were taken at the start, midpoint and end of the leach period.

The results are summarized below:

- No detectable anions or cations were noted in any of the samples. While the samples exhibited a slight increase in TOC and particles during the initial stages of testing, particle counts and TOC decreased to steady state levels as the test progressed – although they each remained slightly elevated relative to the baseline readings,’

- Sodium and calcium were detected at concentrations near the Reporting Limit (RL) in the “Start of Leach” ion chromatography (IC) sample. Neither cation was observed in either of the subsequent IC samples.

- During the trace element analyses, only sodium was detected in the “Start of Leach” sample and was detected at the same concentration as the IC sample. Calcium was not detected in this sample. The sample was rerun to confirm the result, using both a standard and high resolution ICP-MS, which is a more definitive method. It is possible the calcium detected in the IC sample was due to some other radical, which co-eluted at the same time that calcium would appear, thus presenting a false positive.

- Resistivity would be expected to remain unchanged at 18.1 mohm-cm throughout the test, based on the anion, cation and trace element results.

Dynamic Leach

Table I: Summary of On-Line Measurements

The test results concluded that Corzan CPVC is no or low leachable. Please contact a Corzan CPVC subject matter expert for further details.

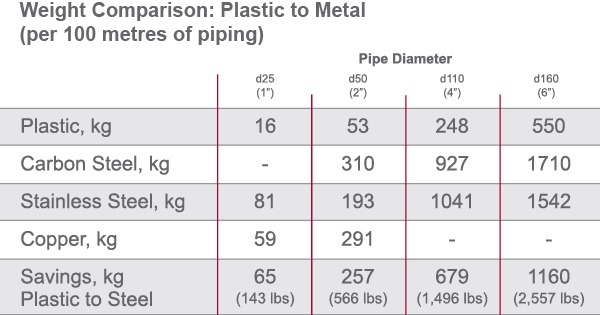

Ease Installation

Corzan CPVC piping systems weigh substantially less than metal piping, which makes them easier to install, modify and maintain. The chart that follows illustrates the weight of plastic piping systems compared to metal materials.

Choose a Proven Piping System

Highly engineered Corzan CPVC complete systems have a proven 60-year history of successful performance across various industries, providing superior resistance to corrosive chemicals, high temperatures and elevated pressures. Entire piping systems can be constructed of Corzan CPVC, with a single material for all components limiting complications, avoiding costly configuration workarounds and reducing overall capital and life cycles costs – especially when compared to stainless steel.

Corzan CPVC piping is available in diameters up to 24 inches to meet boiler system requirements, with Corzan pipe and fittings available globally through Lubrizol’s network of partner manufacturers. Contact a Corzan CPVC piping system expert for application engineering support or to schedule a free technical consultation.

Details for this blog were taken in part from the following:

https://cdn2.hubspot.net/hubfs/2569192/Ebook_Metal%20Alternatives_V1.pdf