The Guide to Cold Weather CPVC Piping Installation

All piping material inherently becomes more brittle in low temperatures. Because of this, we are often asked, “What is the absolute minimum temperature CPVC can be installed at?”

The short answer: there is no known absolute minimum installation temperature for Corzan® CPVC. One manufacturer of industrial Corzan CPVC, IPEX, confirms that high strength joints have been made at temperatures as low as –15°F (–26°C). Oatey and Weld-On, two leading solvent cement manufacturers, assure the same.

Regardless of an absolute minimum, all low temperature installations—below 40°F (4°C)—require heightened attention to detail to create a dependable piping system.

How to Design a Piping System for a Cold Weather Installation

When designing a piping system, architects must correctly account for thermal expansion and contraction. The most important factor to account for is temperature differential, which is the difference between the maximum and minimum temperatures the piping system will be exposed to during its life.

If the pipe is being installed in cold weather, what is the highest temperature the piping will be exposed to, including both internal and external temperature?

Temperature change is just one of the four design factors you must consider when designing piping system expansion loops. Learn about each of the four thermal expansion and contraction design factors and ways to account for expansion and contraction.

Or, check out the free Corzan CPVC Expansion Calculator to easily aid in design of CPVC piping systems based on specific key factors of your system.

Cutting and Handling In Low Temperatures

When the temperature is near or below freezing, take extra precaution when cutting and handling the pipe.

Handling the Pipe in Cold Weather

To prevent damage, proper care should be exercised when transporting, storing or installing Corzan piping. Do not drop or drag the pipe or fittings.

Thoroughly inspect the material for cracks, gouges or other signs of damage. Particular attention should be given to the inside surface of the part, as improper handling can result in damage that appears only on the inside surface.

Cutting the Pipe in Cold Weather

Best results are obtained by using fine-toothed saw blades (16 to 18 teeth per in.) with little or no offset (0.025 in. max.). A wheel cutter can also be used. Ratchet cutters are not recommended in cold environments because they compress the pipe increasing the risk of cracking the pipe.

After performing a cut, check the end for potential new cracks. If there are any, recut the pipe two inches beyond the visible end of the crack. Once the pipe has been inspected and is free of cracks, move on to joining.

Cold Weather CPVC Joining: Solvent Cement

Solvent cement is the recommended joining method for many industrial CPVC systems and applications. The cement’s combination of solvents and resins binds the molecules of the pipe and fitting together, making a reliable joint that maintains the performance of the piping material.

In cold weather, certain precautions must be followed to ensure the solvent cement joint reaches peak performance.

Primer Application

In cold weather, pipe and fittings are more resistant to solvent penetration. This means solvents penetrate and soften the pipe and fitting surfaces more slowly than in warm weather. An aggressive primer may need to be used to adequately pre-soften the surfaces.

Solvent Cement Cure Time

Also, cold temperatures require extra time for the joint to cure. During curing, the solvent flashes off, or evaporates. Once fully cured, the fused joint will assume most of the same performance characteristics of a continuous piece of material.

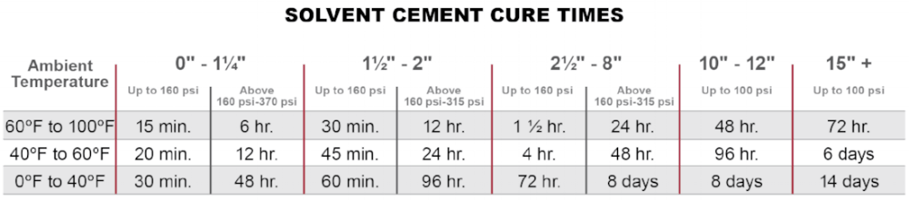

Below is a general guide for solvent cement cure times, but you should follow the solvent cement manufacturer’s label specific cure times.

Weak joints can result if the system is pressure tested or put into operation before the joint has fully cured, causing issues within the system, specifically leaks.

Other Solvent Cementing Tips

Other key tips to follow in cold weather solvent welding, from solvent cement manufacturer, Weld-On:

- Prefabricate as much of the system as possible in a conditioned space.

- Store cements and primers in a warmer area to ensure they remain fluid.

- Take special care to remove moisture from the ends of the pipe.

- Use the most aggressive available primer before applying cement.

- Vigorously shake or stir the cement before use.

Are You Facing a Cold Weather CPVC Installation?

If you have questions about system design or installation for a cold weather environment, the details will be more important than ever to assure a reliable system. Talk with our product and engineering experts. They’re ready and eager to answer any questions you may have.