Why Pipe Weight Matters

Weight matters for piping systems used for industrial applications. It makes sense that a lightweight piping system such as chlorinated polyvinyl chloride (CPVC) is easier to transport, store and handle than heavier piping like steel.

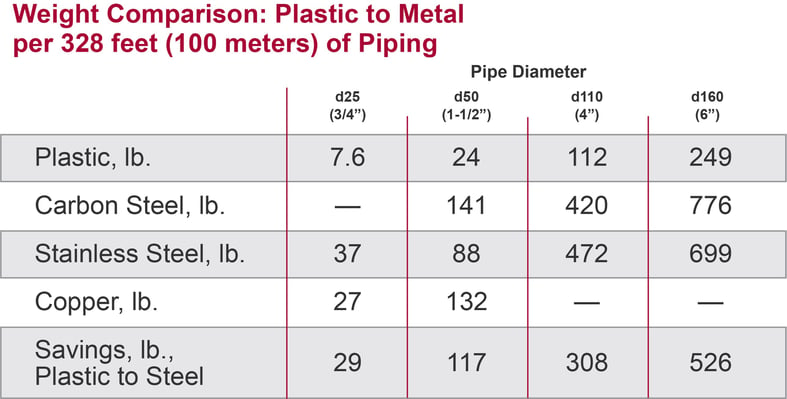

Consider that CPVC piping is approximately one-third to one-sixth the weight of comparatively sized metal piping, depending upon the type of metal. With labor and installation costs often representing more than half of the total piping system investment, CPVC piping has the potential to result in significant installation and maintenance savings.

A lightweight piping system offers other important advantages, too, including reduced risk of worker injury.

Easy, Safe Installation

CPVC’s light weight means fewer workers are needed to handle and install the piping system, which requires only a few handheld tools. The weight associated with heavier materials such as steel creates the risk of worker strains and sprains during installation and often requires the use of expensive heavy machinery to move and place the piping and ducting, which can create its own safety issues. The following chart compares the weight of common piping materials.

CPVC also eliminates the fire risk associated with joining steel piping via welding. Metal piping systems require a costly and time-consuming hot weld process that often results in the joints becoming the weakest part of the piping system. The joints have the potential to fail and possibly expose workers to dangerous chemicals.

Many industrial facilities have areas classified as high hazard based on soaring temperatures and the use of hazardous chemicals that create flammability concerns. Since welding is one of the most common methods of joining metal piping, onsite fabrication is unrealistic in certain areas based on safety concerns relative to sparks and open flames resulting from metal-to-metal contact. Highly flammable chemicals have the potential to catch fire near an ignition source and entire areas must be shut down to perform repairs in flammable risk areas.

Corzan® CPVC piping is generally joined by a two-step solvent cement welding process that can be performed almost anywhere without heat, flame or hot work permits. Solvent cement fuses CPVC to the fittings for a highly reliable joint that becomes the strongest part of the entire piping system.

This method allows any trained plant maintenance engineer or mechanical contractor to install or modify a CPVC system. Proper training, however, is essential as incorrectly applied solvent cement can cause joints to fail. ASME B31.3 bonder training is available and highly recommended for all installers.

Because lightweight CPVC is joined via solvent cement, flanging or threading, onsite piping system fabrication, modifications and repairs can quickly, easily and safely be accomplished without a welder, expensive tools or heavy equipment. And again, no hot work permits are required.

Installation and maintenance ease are especially important for facilities that rely on in-house personnel for piping system repairs and updates.

Fewer Hangers and Supports

Piping system weight is a consideration when designing the supports for piping and ducting. Hangers and supports must be correctly spaced as too much space between supports adds unnecessary stress, resulting in deflection and sagging. Too little spacing means extra supports and unnecessary expenses.

CPVC has an advantage over other thermoplastics in that it maintains its structural integrity at elevated temperatures, requiring fewer supports. This benefit can result in savings in material, design and labor costs – depending on the size of the system.

Although support spacing is less for CPVC piping than for metal, CPVC is not as rigid as traditional metal systems, which require additional supports, The number and spacing for hangers and supports typically depend on the system conditions and piping or ducting requirements.

Other Advantages

Corzan CPVC is lightweight and highly reliable, offering advantages such as corrosion resistance and chemical compatibility, superior mechanical strength and the highest impact resistance of any CPVC piping material as defined by ASTM D1784. The material offers excellent hydraulic capabilities and pressure ratings up to 200°F.

In addition, Corzan CPVC has a heat distortion temperature (HDT) of 230°F, the highest HDT rating in accordance with ASTM D1784. Standard CPVC has an HDT rating of 212°F, which means Corzan piping will retain its straight profile when other CPVC systems sag or bend.

Corzan CPVC piping ensures long-term, cost-effective performance and is backed by 60 years of successful application in industries worldwide. Contact us or our partner manufacturers for a free suitability review and technical assessment.

Some details in this blog were taken from the following:

https://www.corzan.com/blog/cpvc-shaves-installation-time-for-wastewater-treatment-plants