CPVC Shaves Installation Time for Wastewater Treatment Plants

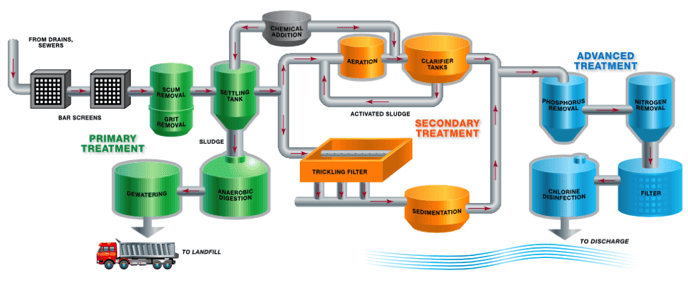

Every year, wastewater treatment plants across the U.S. treat an estimated 61 cubic kilometers of wastewater – roughly the same volume of water that flows over Niagara Falls during a 12-month period. The wastewater treatment process requires large vessels and piping systems to convey and handle very polluted water and highly corrosive and caustic chemicals.

Metal piping is seldom an option for wastewater treatment plants because of the highly corrosive environment. CPVC piping has proven an effective choice based on its excellent hydraulic capabilities, corrosion resistance, mechanical strength and lower life-cycle costs.

CPVC piping also requires significantly less time for installation, which is essential whether the plant is new, expanding or replacing an existing piping system. The cost savings can be substantial since installation time and related expenses can account for more than half of a piping system’s total price.

Less Labor and Equipment

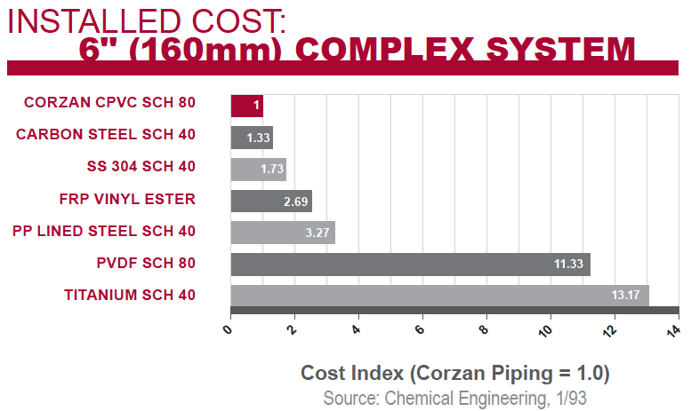

Chemical Engineering Magazine produced the following chart showing the cost of installing 6-inch Corzan CPVC® piping compared to metal and other thermoplastics.

Corzan CPVC’s comparably low installation cost reflects the fact that the piping system is significantly faster and easier to install than traditional metal systems. CPVC weighs 1/8th as much as comparably sized steel piping, with a 6-inch schedule 80 Corzan pipe weighing about six pounds per foot compared to 25 to 29 pounds per square foot for the same size steel piping (based on sampling of steel piping from various manufacturers).

The weight difference between a 50-foot piece of Corzan piping versus the same length of steel piping is approximately 1,150 pounds, which translates into fewer workers required to handle, install and secure the CPVC piping. The system is also easier to install in close quarters – requiring only a few handheld tools – with no need for heavy equipment to lift the piping material into place.

Simple Two-Step Solvent Cement Installation Process

Metal piping seams are typically welded together and require intense heat and often a metal filler. In addition, hot work permits must be obtained in rated areas, which can be time-consuming and expensive.

CPVC piping is fused together using a straightforward, two-step solvent cement process that requires about half the time to join piping and fittings compared to welding. There is no need for a designated welding area, and installation requires neither an experienced, certified welder nor hot work permits.

Solvent cement chemically fuses the CPVC pipe to the fitting for a highly reliable joint that becomes the strongest part of the entire piping system, able to withstand the harsh chemicals, high temperatures and pressure present in wastewater treatment plants. Any trained mechanical contractor or plant maintenance engineer can change, repair or modify a CPVC piping system, with the training required completed onsite in less than 15 minutes and without specialized equipment.

Proper training is essential as incorrectly applied solvent cement or cement used in the wrong application can cause joints to fail. Training is available through coalitions, local union halls, training centers and trusted companies such as Lubrizol Advanced Materials.

The two-step solvent cement welding process used to join CPVC piping also facilitates onsite fabrication, saving plants time and reducing costs.

Versatility and Performance

Sewage, industrial, agricultural and other types of wastewater treatment plants depend on CPVC piping in applications around the globe. CPVC piping can be used virtually anywhere piping is employed to transport a fluid or other medium, as illustrated below.

Corzan CPVC piping systems shave installation time and offer many performance and maintenance advantages while ensuring durability and reliability over the long term. The piping system is backed by a 60-year history of success across a wide range of industries worldwide.

Corzan CPVC piping systems shave installation time and offer many performance and maintenance advantages while ensuring durability and reliability over the long term. The piping system is backed by a 60-year history of success across a wide range of industries worldwide.

For further information about Corzan CPVC, contact a Corzan CPVC System Consultant or one of our partner manufacturers. Lubrizol product and engineering specialists are always on call to provide advice, information and training throughout the life of a Corzan CPVC piping system.

Details for this blog was taken, in part, from the following:

https://www.corzan.com/en-us/cpvc-use-in-wastewater-treatment-plants

https://www.corzan.com/blog/cpvc-pipe-joining-methods-impact-efficiency-productivity

https://www.corzan.com/en-us/metal-v-cpvc-piping-systems