Can CPVC Piping Systems Be Used with Sulfuric Acid (H2SO4)?

Sulfuric acid is one of the most dangerous chemicals in the world. Because of its corrosiveness, high concentrations can cause expensive damage to industrial machinery, and even weak concentrations can cause eye, nose, throat and skin burns in people, along with chronic respiratory damage in case of long-term exposure. Quality, reliable piping material is essential for handling this extremely corrosive chemical. Chlorinated polyvinyl chloride (CPVC) like Corzan® CPVC has a proven record of performance against sulfuric acid, especially compared to many metals and other plastics.

Sulfuric Acid Production Creates Intense Demands on Piping

When processed and handled properly, sulfuric acid is one of the most useful industrial chemicals and is an important ingredient in fertilizer, batteries, detergents and other products that are used around the world every day. Sulfuric acid is a by-product of zinc. When zinc ore, which also contains sulfur, is heated to 1750°F (950°C), it releases sulfur dioxide gas, which is then collected, cleaned and processed into sulfuric acid. This powerful oxidant has strong dehydrating properties, which is why it is so damaging to most materials and why manufacturers face such challenges in production facilities.

One such facility is one of Europe’s largest producers of zinc, which is also a leading producer of sulfuric acid. This company, founded in 1906, produces over 130,000 tons of zinc and 225,000 tons of sulfuric acid every year at its plant in Northern Germany. They’ve had over 100 years of experience with sulfuric acid’s effect on machinery and pipes. As a result, they are always looking for products that can better handle the temperatures, pressures and concentrations found in their sulfuric acid production process.

When this European company began producing sulfuric acid, they used steel pipes to transport the material through the various stages of the production process. However, due to the corrosiveness of the acid, the pipes had to be regularly replaced to avoid bursts.

Later, the original steel pipes were replaced with steel pipes that had been lined with lead, which helped reduce the corrosion, but made the pipes extremely heavy and difficult to install, necessitating extra hangers to keep them from bending and sagging.

More recently, this sulfuric acid manufacturer experimented with pipes made of polyethylene (PE) and PVC reinforced with a fiberglass sheath. These last two systems were both more corrosion-resistant and easier to install than the metal pipes, but still tended to burst due to the changing temperatures and pressures of the sulfuric acid in the system.

The Switch to CPVC

In 1992, a Corzan Material and Piping Solutions sales engineer introduced a new option – CPVC pipe. Used successfully in the United States for years, CPVC’s corrosion resistance and durability made it the perfect material for their sulfuric acid system.

A close-up image of the sulfuric acid plant’s Corzan CPVC installation

A close-up image of the sulfuric acid plant’s Corzan CPVC installation

The plant manager and plant engineer were skeptical but agreed to install a few meters of Corzan CPVC pipe as a test to determine whether it would work as well as Lubrizol claimed.

Here’s what the experiment yielded:

- Quick installation: Although the installer had never worked with CPVC before and the Corzan CPVC partner manufacturer had never dealt with sulfuric acid, the CPVC pipe was so easy to work with that the installation was completed in just one day. Based on this success alone, the installers were so impressed with the CPVC pipe that they said they plan to use it again whenever and wherever it meets their needs.

- Problem-free performance under extreme conditions: During the one-year test, the Corzan CPVC pipe performed flawlessly, and the facility has experienced no problems of any kind. In fact, both the plant manager and plant engineer have learned that, along with CPVC’s ability to stand up to high temperatures, pressures and corrosion, it also easily handles environmental extremes.

The science of Corzan CPVC is the key to these results. The additional chlorine in CPVC’s polymer chain protects it from the degrading effects of corrosive acids. High-quality material like Corzan CPVC is carefully engineered, formulated and tested to perform even in extreme situations. For example, many industrial environments use piping systems that are partially or completely installed outdoors which may experience prolonged UV or freezing exposure. To address this issue, Corzan CPVC uses heavy amounts of carbon black and titanium dioxide (TiO2). Both additives are widely recognized as excellent ultraviolet blocking agents and effectively protect the polymer backbone from the effects UV light.

On the cold end of the spectrum, Corzan CPVC is equally durable. Corzan CPVC has no known absolute minimum temperature for installation in outdoor environments. As an amorphous structured material that operates below the glass transition temperature (Tg), Corzan CPVC does not have a freezing point. Instead, the medium carried or held inside a system made with Corzan CPVC typically dictates minimum use temperatures. A general guideline of -15°F (-26°C) is typically used as the piping system’s lower limit.

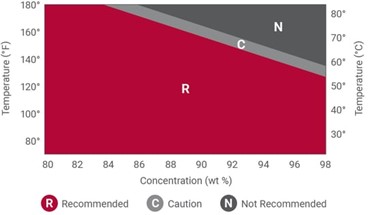

Corzan CPVC chemical resistance to sulfuric acid chart. Contact the Corzan CPVC team for chemical resistance details.

The bottom line: CPVC is an ideal solution for sulfuric acid applications. The test was such a success that, after the test year, the facility replaced all the old pipes in their sulfuric system with Corzan CPVC pipe measuring 3-in. (80mm) in diameter, with a pressure rating of 10 bar (145 psi). They also reported plans to expand Corzan CPVC installations to other parts of the plant that have previously suffered from high temperatures, pressures and corrosion.

The best proof of confidence in their Corzan CPVC pipe system can be seen in the plant’s lab areas. The pipes containing highly concentrated sulfuric acid run directly over open worktables, something that would be unthinkable with steel or other kinds of plastic pipe because of the danger of a burst. For the Corzan CPVC pipe, though, this isn’t a problem.

Sulfuric Acid: One of Corzan CPVC’s Top 10 Chemicals for Suitability

Corzan CPVC is backed by more than 60 years of experience and research and delivers fast installation and long-term results for sulfuric acid piping applications. Learn more about how different piping materials respond to sulfuric acid and why Corzan CPVC is more suitable for and trusted by specifying engineers for this corrosive chemical.