Due Diligence During Piping System Selection and Installation Helps Prevent Plant Bottlenecks

A bottleneck within a plant operation generally occurs when a portion of the process throughput slows down, reducing process efficiency and profitability. The identification of process bottlenecks is in itself a skill and an artform. Proper due diligence during the design, material selection, procurement and installation of a piping system can eliminate many of the bottlenecks that are often associated with metallic piping systems.

Proper due diligence can also significantly reduce installation and maintenance costs while ensuring system reliability over the long term.

The Engineering Phase

Due diligence during the engineering phase involves thoroughly evaluating materials to confirm they can withstand the high heat and elevated pressure characteristic of many industrial applications. This can be described as the PTM: Pressure, Temperature, and Medium. Ask the question, are the materials capable of efficiently and effectively handling the medium that will flow through the piping system? If so, what is the expected life in the specified operating conditions?

Over the years, metal has proven capable of satisfying piping system heat and pressure requirements. But as more non-metallic systems were specified, industries within the U.S. rely on ASTM D2837 – the Standard Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for Thermoplastic Pipe Products” – to determine a piping material’s pressure-bearing capability.

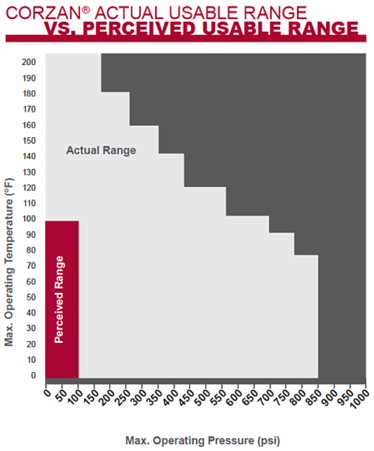

The test subjects a number of samples to a range of pressures that will cause the pipe to rupture at various times – from a few hours to over 10,000 hours. The following graphic illustrates the maximum operating temperature and pressure range as determined by ASTM D2837 for Corzan CPVC, which is a thermoplastic. Many engineers’ perception of CPVC’s operating capabilities fall well short of reality.

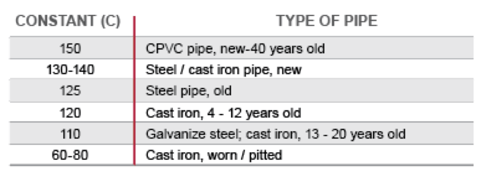

Determining the carrying capacity and friction loss for a piping material is also important during the engineering phase. The Hazen-Williams formula is generally the accepted method for calculating piping system friction head loss.

The fluid flow table that follows provides the friction head loss values of various piping materials. CPVC has a Hazen-Williams C Factor (surface roughness constant) of 150. The values in the table account for both old and new piping materials.

CPVC piping has a smooth inner surface that resists scaling and fouling. Friction pressure losses in the fluid flow, therefore, are minimized from the beginning and do not significantly increase as the system ages.

Other factors to consider during the engineering phase include thermal expansion of the piping system, corrosion resistance, material weight and pipe support spacing, fire safety, etc.

The Procurement Phase

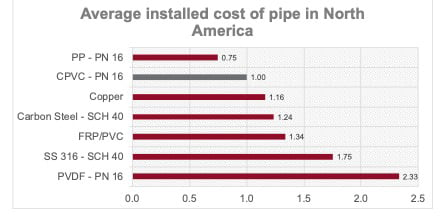

Due diligence during the procurement phase requires consideration of not only direct material costs but installation and life-cycle costs. Labor and related expenses during installation can account for more than half of the total piping system investment and include material transportation, handling and storage, and the cost to install hangers for support and join pipe with fittings.

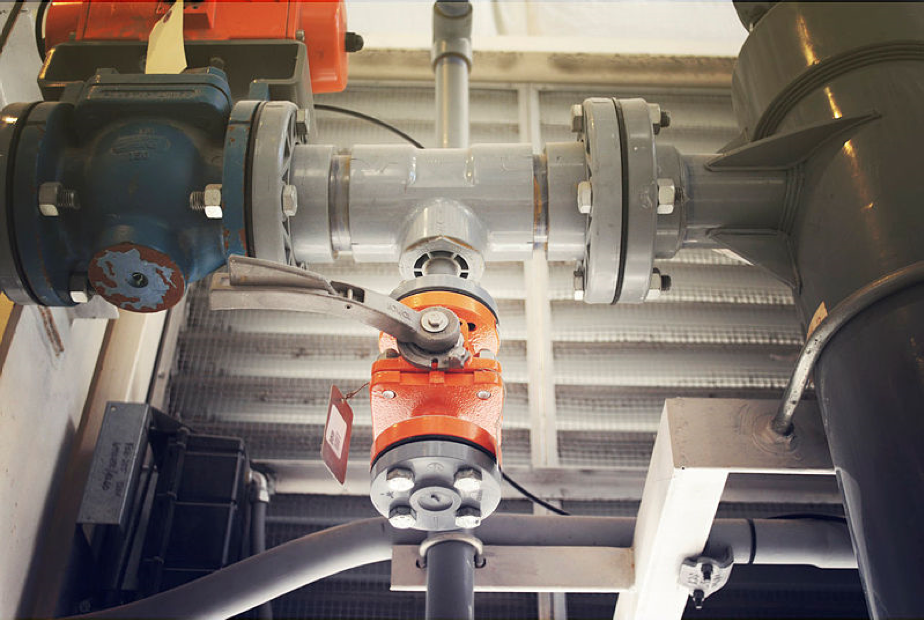

Engineers are specifying more non-metallic systems such as Corzan CPVC because the materials are lighter than metal and less expensive to install. CPVC is generally one-eighth the weight of steel piping systems of comparable size. And while CPVC will require more hangers for support than steel, Corzan Piping Systems can be installed with little disruption to plant operations. Steel piping, on the other hand, generally requires some type of lift device during installation and could result in costly downtime.

Steel piping also requires hot work for installation and has the potential to create a safety hazard in the presence of even a small chemical leak. CPVC is often installed using a two-step solvent-cement process that involves chemically fusing pipe to fittings for a highly reliable joint.

The graphic that follows shows the installation costs for various types of piping systems commonly used in North America.

A properly installed CPVC piping system will reduce life-cycle costs as it requires little to no maintenance compared to metal systems, which are highly vulnerable to internal and external corrosion. Metal is also susceptible to flow-restricting scale buildup, which increases pressure drop and can contaminate the process.

The Installation Phase

Due diligence is essential during the installation phase of a CPVC piping system to ensure the system’s long-term performance. Care should be exercised when transporting and installing CPVC piping to prevent damage. And, materials should be stored and shipped only with other non-metallic systems and never dropped or dragged.

Installers must understand the key characteristics of the piping material specified and install the material according to the manufacturer and design guidelines. Installers should also inspect both the inside and outside of the piping system for cracks, gouges or other types of damage before beginning installation.

Depend on Proven Performance

Engineers and designers have many choices when selecting piping systems for industrial environments. Proper due diligence during the engineering, procurement and installation phases of a piping system will help prevent process bottlenecks that disrupt operations and decrease productivity.

Choosing the right piping system for the application will help ensure long term system reliability and performance with minimal life-cycle costs. Corzan CPVC piping systems have over 60 years of proven success in a range of challenging industrial applications, providing an excellent balance of properties to meet specific performance needs.

To learn more about how Corzan CPVC prevents costly bottlenecks in plant operations, contact a Corzan Piping System Consultant for a free technical assessment.