How Corzan® CPVC Assures Quality and Consistency

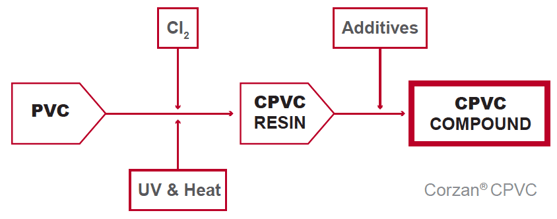

Contrary to what some may assume, Corzan® Industrial Systems does not produce the final CPVC products used in industrial plants around the globe. Rather, we engineer and manufacture CPVC compound from PVC resin, as the chart depicts below.

The Corzan CPVC compound that is shipped to partner manufacturers in pellet or powder form has been fortified with additives to provide superior strength, UV resistance and improved processability for manufacturers.

Our proprietary CPVC compound also offers inherent resistance to corrosion, high temperatures and high pressures no matter what final form it takes. Our partner manufacturers transform Corzan CPVC pellets and powder into the piping, fittings, sheet, shapes and other CPVC products end users receive.

This process begs the question from potential customers: How does Corzan Industrial Systems ensure each product offers consistent quality regardless of when, where or by whom the product is manufactured?

The Role of Partner Manufacturers

Once a partner manufacturer receives Corzan CPVC compound, it is either extruded or injection molded, depending on the geometry of the product.

CPVC extrusion is the process used to create long, continuous shapes, such as piping and sheet. For all other shapes, such as for fittings, valves and flange adapters, manufacturers employ injection molding.

During both processes, the CPVC compound must be melted down using heat and pressure. The CPVC molecules disentangle and are molded into the proper geometry before entangling as the product cools and hardens. Higher heat and pressure result in better molecular entanglement, and thus, more durable CPVC products.

Quality Assurance Program

Each manufacturer is free to establish and optimize its own manufacturing processes to ensure the greatest efficiency. At the same time, Corzan Industrial Systems has established a quality assurance program all partners must comply with.

This program requires manufacturers to test samples above and beyond the baseline ASTM tests from the manufacturing line at specific intervals to ensure the products satisfy minimum requirements.

Corzan Industrial Systems’ facilities and our partners’ facilities are all ISO 9000 certified, confirming their consistent quality management system standards. It’s also worth noting that most manufacturers may also establish their own quality assurance programs that exceed the criteria of Corzan CPVC’s program based on ASTM standards.

To test samples from the manufacturing line, each manufacturer has a control lab near the production facility. The testing frequency and method varies.

As an example, pipe dimensions must be measured at the beginning of every shift and at each hour. In the event that a sample does not meet the requirement, all preceding products must be pulled and examined. The machine is also recalibrated and tested to ensure the issue is resolved.

The following attributes are required to be tested at regular intervals to assure product consistency and quality.

Pipe and Fitting Dimensions

Dimensions for each pipe and fitting size must be measured for appropriate diameter, wall thickness (for schedule 80 or 40 requirements) and length.

ASTM D2122 defines the tolerance level of each measurement. Notably, the Corzan Quality Assurance Program’s room for error is slightly less than that of the ASTM standard.

The diameter of each piece must be within a certain range to enable proper joining of pipes and fittings.

For wall thickness, the measurement must be at or above a certain size, as a thinner pipe may not exhibit the same pressure rating or may require more frequent support or hangers.

Pipe Impact

The impact resistance of a given manufactured pipe indicates its suitability for service and quality of processing. In other words, a poorly processed pipe will not pass the falling weight test.

If a sample does not pass the impact test, it likely means the CPVC molecules did not fully entangle when forming the pipe. Those that fail could break during handling, installation or while in service. A failed test is often the result of running the line too cold.

To test for impact resistance, the ASTM D2444 prescribes how the falling weight test is to be performed, including:

- The kind and shape of the weight used

- The height at which the weight is dropped

- How many samples are used

- What is considered a pass or a fail

Partner manufacturers must perform this impact resistance test once per shift.

Pipe Flattening

Similar to the impact resistance test, pipe flattening demonstrates how well the pipe material has been forced and fused together. If not formed effectively, the pipe will prematurely break during the flattening test.

ASTM 441 provides how this test is to be performed and what qualifies as a successful test.

To perform the test, two parallel plates must compress the sample until the distance between the two plates is 40% of the outside diameter of the pipe or until the walls of the pipe touch, whichever occurs first.

Though not required, if processed correctly, the vise should be able to squeeze the pipe until the pipe walls touch. And, once removed from the plates, the CPVC should return to a close approximation of its original shape.

Pipe Burst

To ensure piping meets the pressure rating specified for the material, the burst pressure test is performed at least once per shift with five samples.

Not only should piping meet the pressure rating expected of the material, it should perform well beyond that rating. In the event of a pressure surge, possibly from a blocked line, industrial plants need assurance the pipe will not burst, as it would cause a potential safety issue and inevitable downtime.

Similar to the preceding tests, this will signify if quality processing has taken place.

According to ASTM 441, a pipe specimen is filled with water at 73°F (23°C) and pressurized until the pipe, inevitably, bursts. The standard lists the minimum psi each pipe size and schedule must meet to be considered a pass.

Fitting Burst

Due to the geometry of fittings, the burst pressure test is the only test required to check for suitability and processing quality.

Specifically, fittings are susceptible to weakness at the knit line. During injection molding, the melted resin is injected into the mold and flows around the center. Where the melted CPVC meets after filling the mold is known as the knit line.

If the temperature and/or pressure are too low, the molecules may not fully entangle at the knit line.

During a burst test, a fitting will almost always eventually fail at the knit line, but successfully processed fittings will meet the minimum psi requirements based on its size and schedule.

Where Is CPVC Used?

Now that you know how Corzan Industrial Systems regulates its manufacturers to ensure end users receive the highest quality products possible, learn about the chemicals CPVC is resistant to and where it is used in various industrial plants.