Corzan® CPVC Stands Up to Harsh Pulp and Paper Processes

In virtually every line of the pulp and papermaking process, freshwater, process liquids and liquors flow through pipes, filters and screens, and are stored in tanks. The need for paper products in our society is critical, as we have seen during the pandemic of 2020. How the process efficiently and responsibly creates the products is a complex maze of technology that transforms trees into paper. Caustic and corrosive chemicals – sodium hydroxide, sodium sulfide, sodium sulfate and sodium carbonate – are at the heart of these processes. In the process flows, there are wide swings in pH levels as chemical reactions galore advance toward making the finished product we use every day.

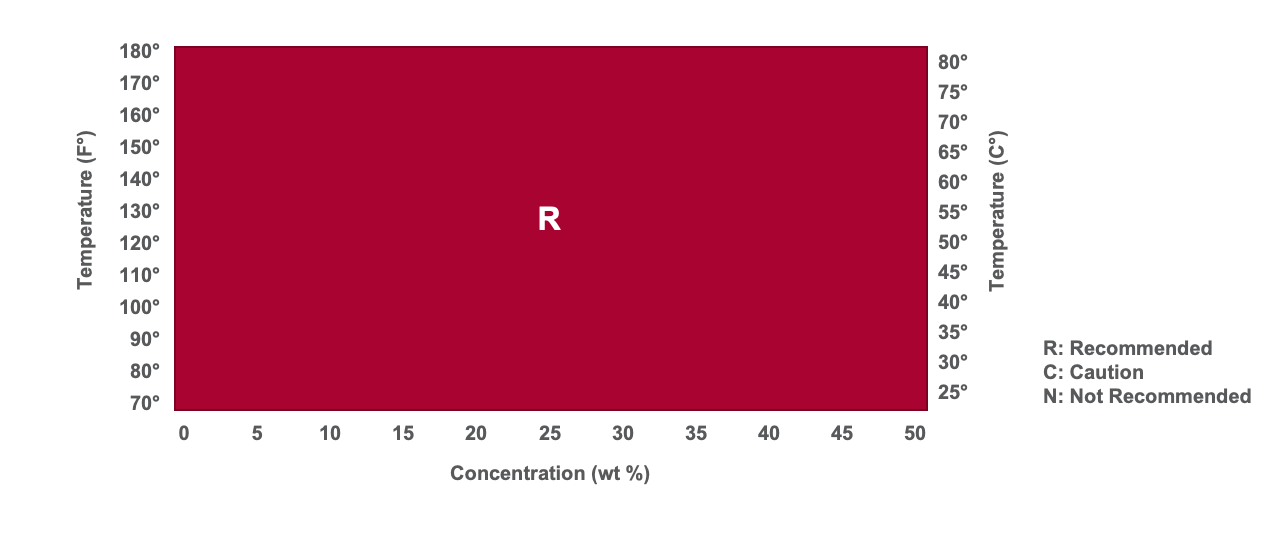

Chemical Resistance of Corzan CPVC to Sodium Hydroxide

In sodium hydroxide applications especially, CPVC compound and product quality matter. The importance of quality increases as the heat and caustic concentration rise.

When older processing systems operate beyond their design capacity, concerns about scale buildup and blockages plague maintenance and reliability personnel. Staying ahead of mineral scale and corrosion can be time-consuming and costly. With metal, these concerns become an inevitable part of the process. While this is necessary to prevent fouling, a precisely-engineered, real-world-tested alternative is close at hand.

Corzan® Material & Piping Solutions Keeps Production Humming

This alternative is a chemically inert piping material with smooth walls impervious to scale and corrosion that can accommodate pH levels running the gamut from high to low. This alternative also ensures optimal flow rates with excellent hydraulic capabilities and pressure ratings up to 200°F (93°C). The material, Corzan® CPVC, is highly suitable choice for pulp and paper applications ranging from influent water, cooling towers and wastewater treatment to chemical processing, boiler feed and demineralized water as well as debarking wash water.

Because the lifetime cost savings over metal are significant, maintenance and reliability professionals should think about displacing metal in these applications. In addition, storage vessels manufactured of traditional carbon steel or stainless steel are being replaced by composites like FRP and Corzan CPVC-lined FRP. Corzan CPVC technology has found a home as the chemical resistance layer in composite construction, providing extended life through its versatile and permeation-free chemical resistance properties.

Other Advantages to Displacing Metal

Whether planned or unplanned, shutdowns are prime opportunities to make the switch for piping components, entire systems and tanks. When time is of the essence, the simple solvent cement joining process for Corzan CPVC pipe and fittings is a significant advantage when combined with locally available materials and technical support specialists to ensure a successful installation.

In addition, project owners have the peace of mind that comes from one of Corzan technology's primary advantages - Corzan pipe and fittings are manufactured exclusively by select partner companies that have met the highest quality standards to ensure the compound achieves its full performance properties in the most aggressive industrial applications.

Corzan CPVC technology has continued to evolve joining mechanisms as well. The traditional solvent cementing process remains the primary method of joining pipe and fittings together. However, mechanical joining techniques have been developed that allow for quick changeover times for critical processes that require modification or temporary connections necessary to keep the process running smoothly. Check out the mechanical joining information.

To evaluate material suitability data and design tools, and other resources in one place, check out our On Spec portal to locate all of the support you need to get started with a system that meets budgets, timelines, and system performance parameters, lasting for the duration of its design life.