Why CPVC Works in Wastewater Treatment Plants

Wastewater treatment processes are more complex than ever, complicated by stricter discharge and odor standards, increased plant flows, fewer sludge disposal options, stronger EPA piping regulations and tighter budgets. The good news is that opportunities exist to select piping materials that improve plant performance while reducing treatment costs and keeping facilities compliant.

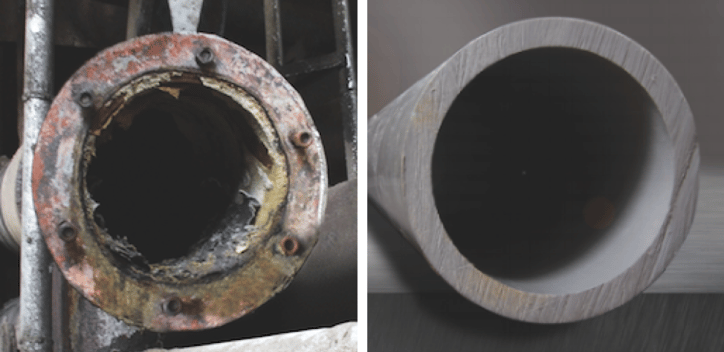

Steel and higher alloys were typically used for wastewater treatment facility piping in the past, but careful analysis shows that CPVC piping often represents a more cost-effective solution to increase reliability over time. While steel is vulnerable to pitting, corrosion and leaks, CPVC eliminates corrosion and provides advantages that impact a facility’s bottom line.

Why Corzan® CPVC is the Best Choice for Wastewater Treatment Facilities

Corzan CPVC has a proven track record of dependable service in wastewater treatment facilities around the world, providing an excellent balance of properties – including corrosion resistance – for greater reliability and user confidence. The system is versatile and works in plants to help them increase their bottom line by avoiding unnecessary shutdowns and boosting productivity.

It should be noted, however, that not all CPVC is the same. Corzan CPVC technology has a history of providing:

- Consistent chemical resistance, with an advanced chemical compatibility program

- Highest impact resistance

- Best in class weatherability

Corzan CPVC is the most specified industrial CPVC technology in the world, with the material available from high performance, global partner manufacturers.

How CPVC Piping Works in Wastewater Plants

Preventing corrosion can be an expensive proposition for wastewater treatment facilities. Chemical corrosion results from strong acids and bases used for water disinfection, pH neutralization and attack from clarification polymers. Microbial corrosion occurs as a result of sludge streams and biological growth in water.

As a thermoplastic, Corzan CPVC is chemically inert to most mineral acids, bases, salts and aliphatic hydrocarbons, providing a lifetime of resistance to corrosive chemicals and water of all purity levels – even at high temperatures. The material is also non-conductive and immune to galvanic corrosion.

Corzan CPVC is resistant to most aggressive chemicals employed during the wastewater treatment process, including the following. Please refer to CPVC Use in Wastewater Treatment Plants for each chemical’s maximum temperature. The Corzan Chemical Resistance Chart also shows Corzan CPVC’s compatibility with over 400 chemicals.

Chemical Resistance of CPVC

Coagulants, Flocculants & Precipitants

Aluminum Sulfate (Alum)

Aluminum Chloride

Calcium Hydroxide (Lime)

Ferric Chloride

Ferric Sulfate

Ferrous Chloride

Ferrous Sulfate

Sodium Aluminate

pH Control

Calcium Carbonate

Calcium Oxide

Carbon Dioxide

Carbonic Acid

Hydrochloric Acid

Magnesium Hydroxide

Magnesium Oxide

Sodium Bicarbonate

Sodium Carbonate

Sodium Hydroxide

Sulfuric Acid

Disinfectants, Odor Control & Color Removal

Ammonia in Solution

Calcium Hypochlorite

Chlorine Dioxide

Fluosilicic Acid, 30%

Hydrofluosilicic Acid, 30%

Hydrogen Peroxide, 10%

Hydrogen Peroxide, 50%

Ozone (Aqueous)

Peracetic Acid

Potassium Permanganate

Sodium Hypochlorite

Sodium Sulfite

Sulfur Dioxide

Corzan CPVC also delivers long-term performance by providing superior mechanical strength and the highest impact resistance of any CPVC piping compound (24448 cell class up to an 8-inch diameter). The system blocks the degrading effects of UV light and ensures optimal flow rates with excellent hydraulic capabilities and pressure ratings up to 200°F.

Where CPVC Works

Corzan meets the stringent demands of various treatment areas within wastewater treatment plants:

Primary Treatment – Corzan CPVC pipe and fittings are unsusceptible to microbial corrosion and resist commonly used chemicals that neutralize acid generated during ammonia nitrification. The material resists scaling and fouling and maintains a constant Hazen Williams C-Factor of 150 throughout the system’s service life, allowing the use of smaller diameter piping.

Secondary Treatment – This process exposes piping to high concentrations of microorganisms as excessive biological growth collects in a clarifier. Microbial byproducts including disinfectants and dichlorination chemicals corrode metallic piping. Corzan systems withstand chemical and microbial corrosion – even when transporting highly concentrated acids and caustic chemicals used for pH control.

Advanced Treatment – Corzan CPVC ensures reliability in cooling tower applications and while handling nominal concentrations of methanol for biological denitrification. The system is suitable for double-containment systems required to transport treatment chemicals underground.

Wastewater Odor Control – Whether a plant is using sodium hydroxide and sodium hypochlorite in its wet air scrubbers at temperatures up to 200°F or metal chelating agents in a liquid redox process, Corzan systems offer the chemical resistance and superior high-temperature performance required for wastewater odor control.

Corzan CPVC is very popular in the chemical feed systems of water treatment and wastewater treatment plants because these systems use strong chemicals such as sodium hypochlorite and ferric chloride.

What Makes CPVC Easier and More Cost Effective to Install

CPVC piping is less expensive to purchase than many high-end alternatives such as stainless steel and titanium. The material is typically installed via a simple solvent cement joining process that fuses the pipe and fittings together at the molecular level to form a uniform piece of material that is highly reliable and often the system’s strongest part.

Installing CPVC is simple and does not require a designated welding area, hot work permits or an experienced, certified welder as with metal piping. Because CPVC is lighter and easier to move, there is no need for heavy equipment. ASME B31.3 bonder training is available and highly recommended for all installers.

To learn more, contact a Corzan CPVC materials expert for a free suitability review or technical consultation or contact a Corzan partner manufacturer.

Details for this blog were taken in part from the following:

https://www.corzan.com/en-us/cpvc-water-and-wastewater-treatment-industry

https://www.corzan.com/blog/why-use-cpvc-in-wastewater-treatment-plants